Customer Requirements

A heavy machinery manufacturer requires machining of oversized bases and structural components (up to 8 meters in length and 32 tons in weight). The process demands high planar grinding accuracy, stable efficiency, and grinding wheels capable of withstanding continuous heavy-duty conditions.

Grinidng Solutions From More Super Hard

Grinidng Solutions From More Super Hard

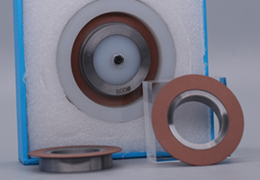

To meet the demanding requirements of an oversized grinding machine (table dimensions 8000×2500mm, maximum grinding width 2650mm), our company provides multi-specification 30A60/80J grinding wheels (diameters D450-D610, thicknesses 28-100mm). Combined with a 35kW high-power motor drive, this solution achieves:

Heavy-load grinding stability: Supports continuous processing of 32-ton workpieces without vibration or power decay

Wide-span coverage: Maximum grinding width of 2650mm accommodates full-surface machining of large structural components

High-efficiency grinding parameters: Linear speeds of 30-50m/s balance rough grinding efficiency with fine grinding surface quality

1. Machine data: Table dimensions: 8000 x 2500 mm

Maximum table load: 32,000 kg

Maximum grinding width: 2650 mm

Width between columns: 3100 mm

Maximum grinding height: 1400 mm

2. Grinding speed: 30 ~ 50 m/s

3. Grinding wheel drive motor power 35 kW

Grinding wheel size:

| Size |

GRIT |

| D450*28*304.8 |

30A60/80J |

| D450*42*304.8 |

30A60/80J |

| D500*42*304.8 |

30A60/80J |

| D500*60*304.8 |

30A60/80J |

| D610*65*304.8 |

30A60/80J |

| D610*80*304.8 |

30A60/80J |

| D610*100*304.8 |

30A60/80J |

Technical Highlights

Technical Highlights

High-rigidity grinding wheel design: 304.8mm oversized bore + reinforced rib structure ensures dynamic balance under heavy loads

30A60/80J grit optimization: Coarse grit for rapid material removal, medium-fine grit for consistent surface finish

35kW motor matching: Delivers ample torque to prevent overload shutdowns and boost production efficiency

Customer Benefits

Single-setup full-width grinding of large workpieces reduces downtime

Grinding wheel life extended by 25% with no abnormal wear under heavy loads

Suitable for ultra-large components including energy equipment, marine components, and heavy machine tool bases

Application Fields

Wind turbine bases, nuclear power structural components

Marine engine mounts, hydraulic press platforms

Large mold steel plates, rail transit components