What is the centerless grinding machine?

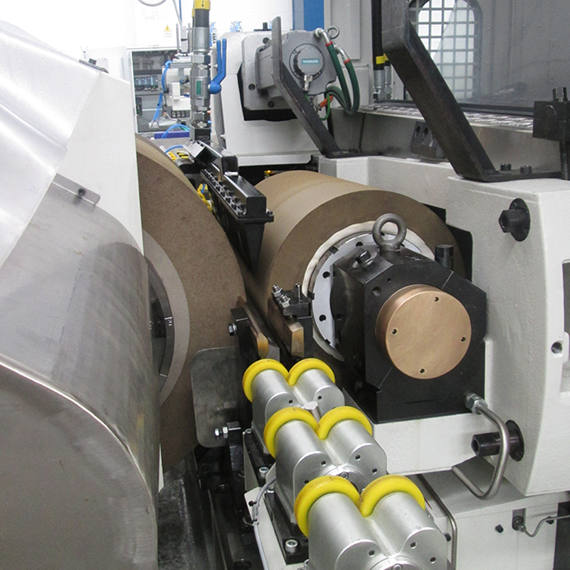

Centerless grinding machine is a type of grinding machine that does not need to use the axis of the workpiece for grinding. It is mainly composed of three mechanisms: grinding wheel, adjustment wheel and workpiece support. The grinding wheel actually performs the grinding work, and the adjustment wheel Control the rotation of the workpiece and control the feed speed of the workpiece. As for the workpiece holder, which supports the workpiece during grinding, there are several ways to cooperate with these three parts, except for stopping grinding, the principle is the same.

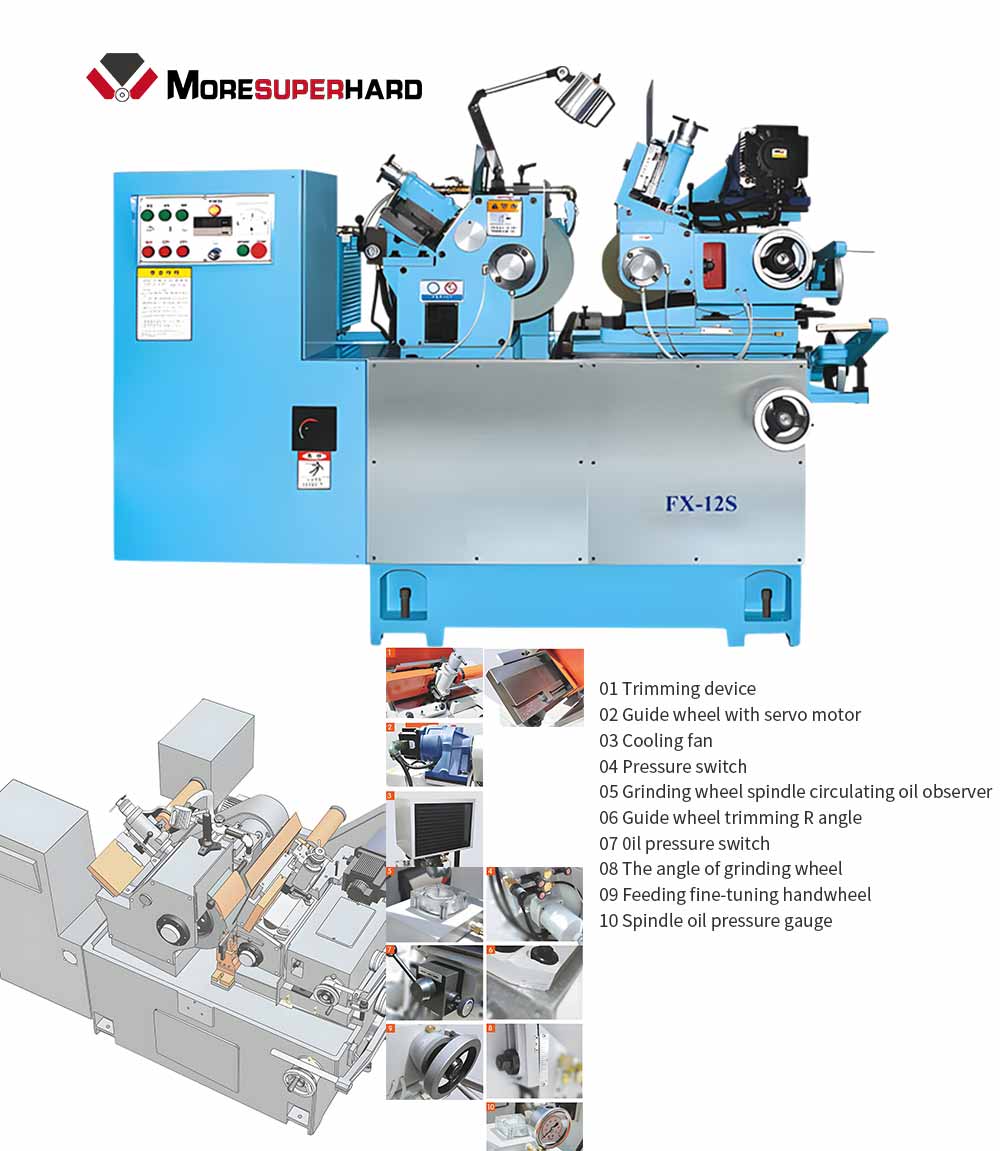

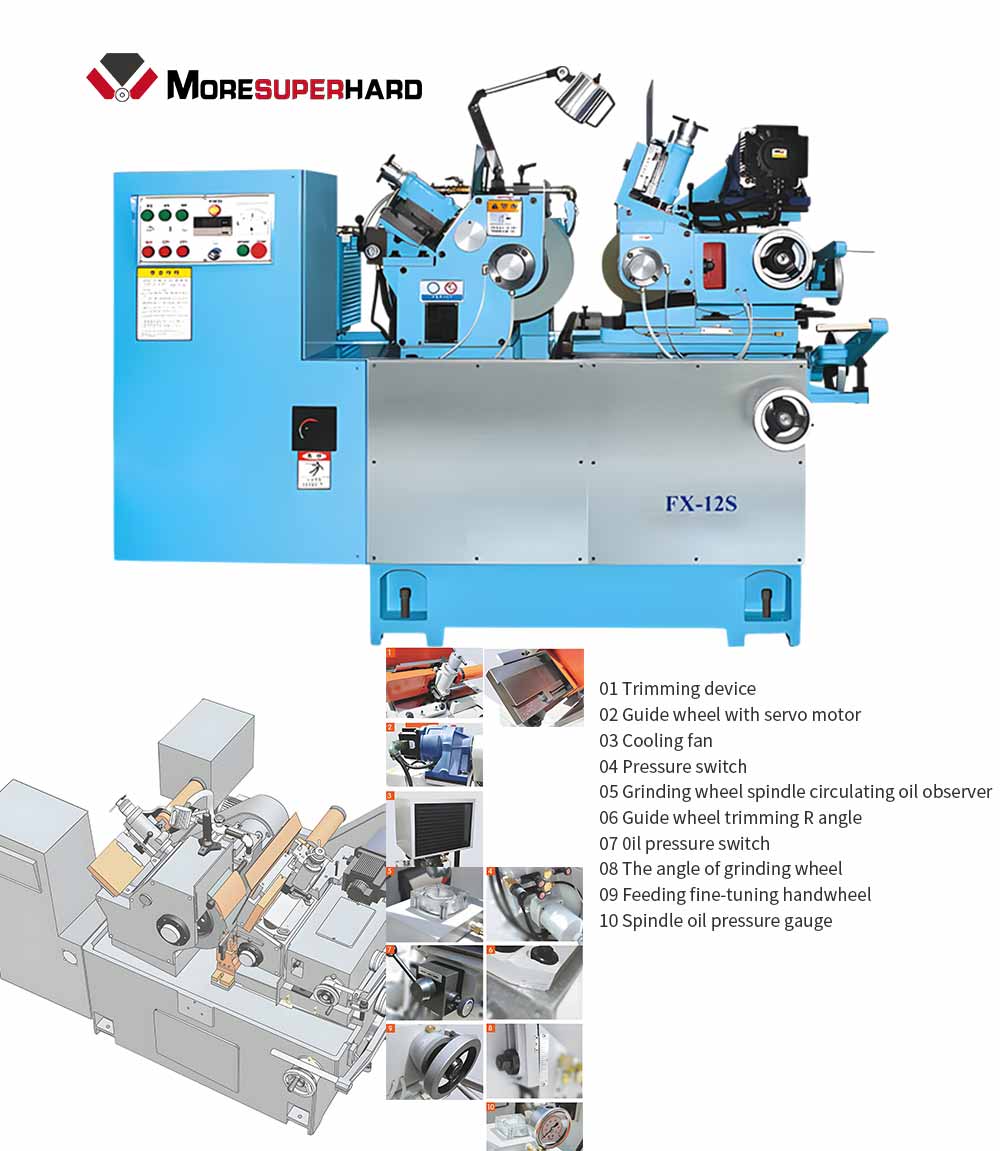

Moresuperhard High Precision Centerless Grinder

High Rigidity Body Structure

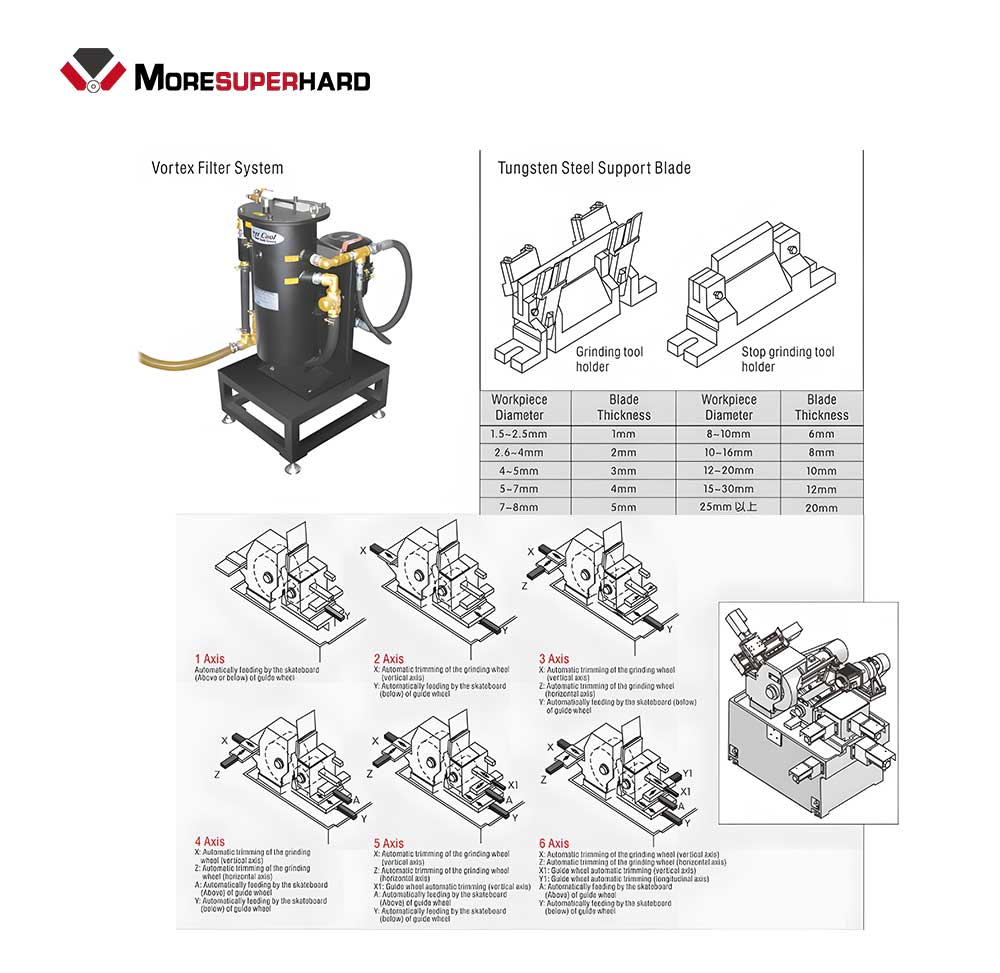

The bottom of the centerless grinding machineis cast from high-grade cast iron (FC30) andnormalized heat treatment.The double V-shapedslide rail design ensures the deformation ofthe inorganic body after long-term use. Fineadjustment of the upper and lower feeds up to 0.001mm.

The grinding wheel trimming device can beadjusted ± 6° and the workpiece and the guidewheeljoint are accurate.The widest selection of models to meet a varietyof grinding needs.The most complete selection of equipment toenhance operational functions and convenienceThe most rigorous testing and quality control ofthe machine guarantees the best performance,precision and lowest failure rate.

.jpg)

01 Manual long material feeding and grinding device (special device)

02 Manual long material receiving and grinding device

03 Long material feeding device (manual or automatic)

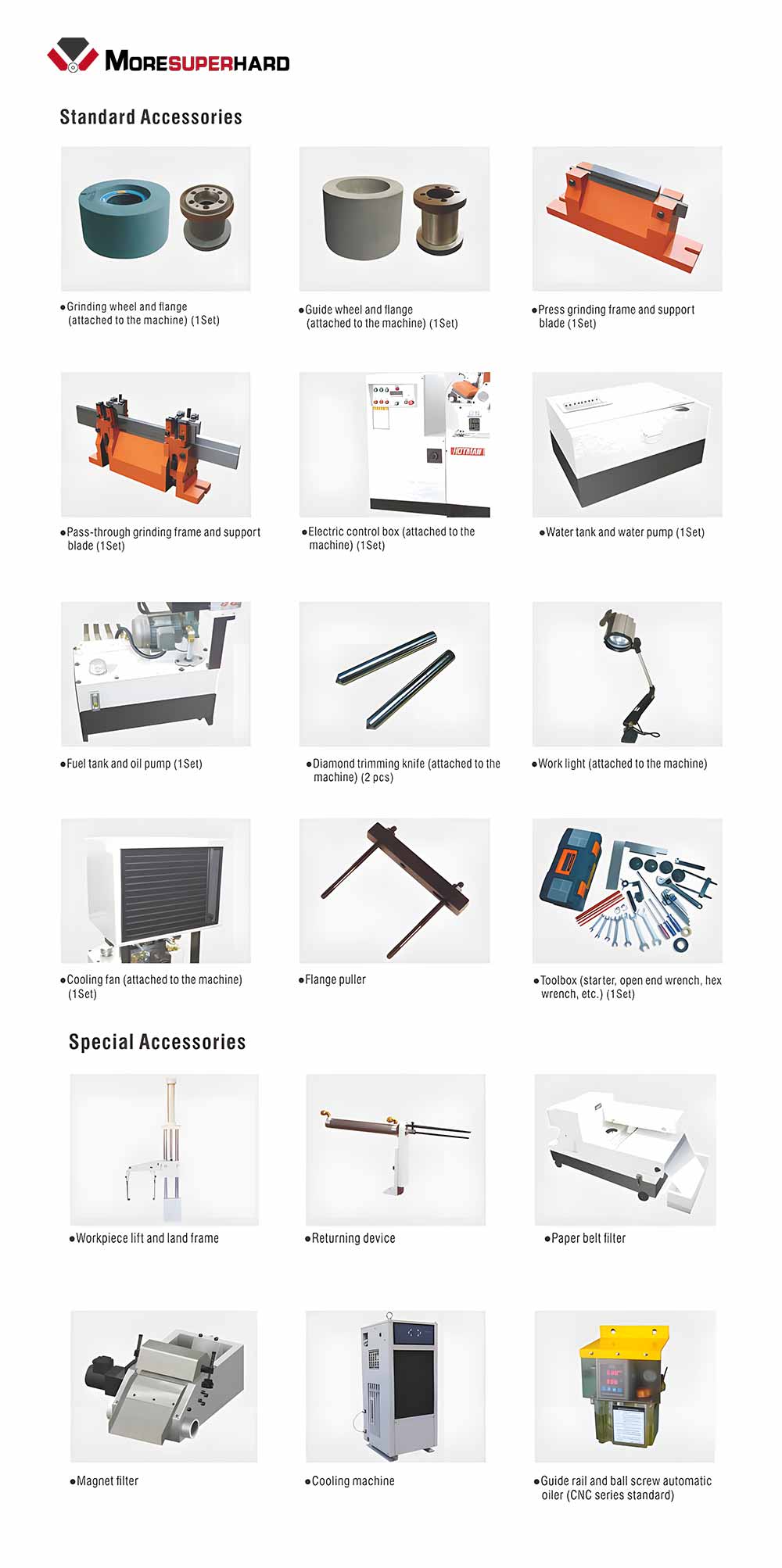

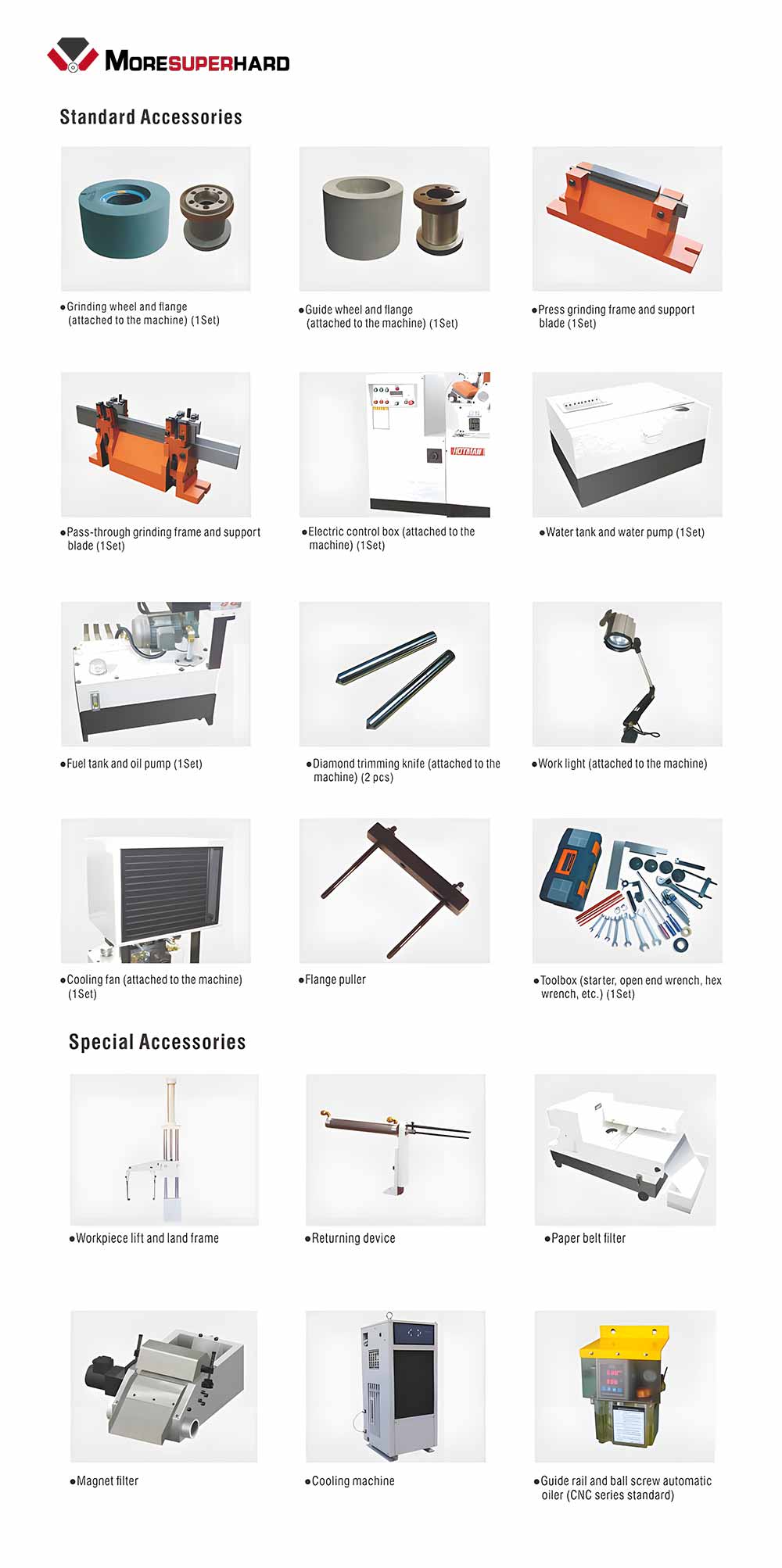

Standard Accessories of High Precision Centerless Grinder

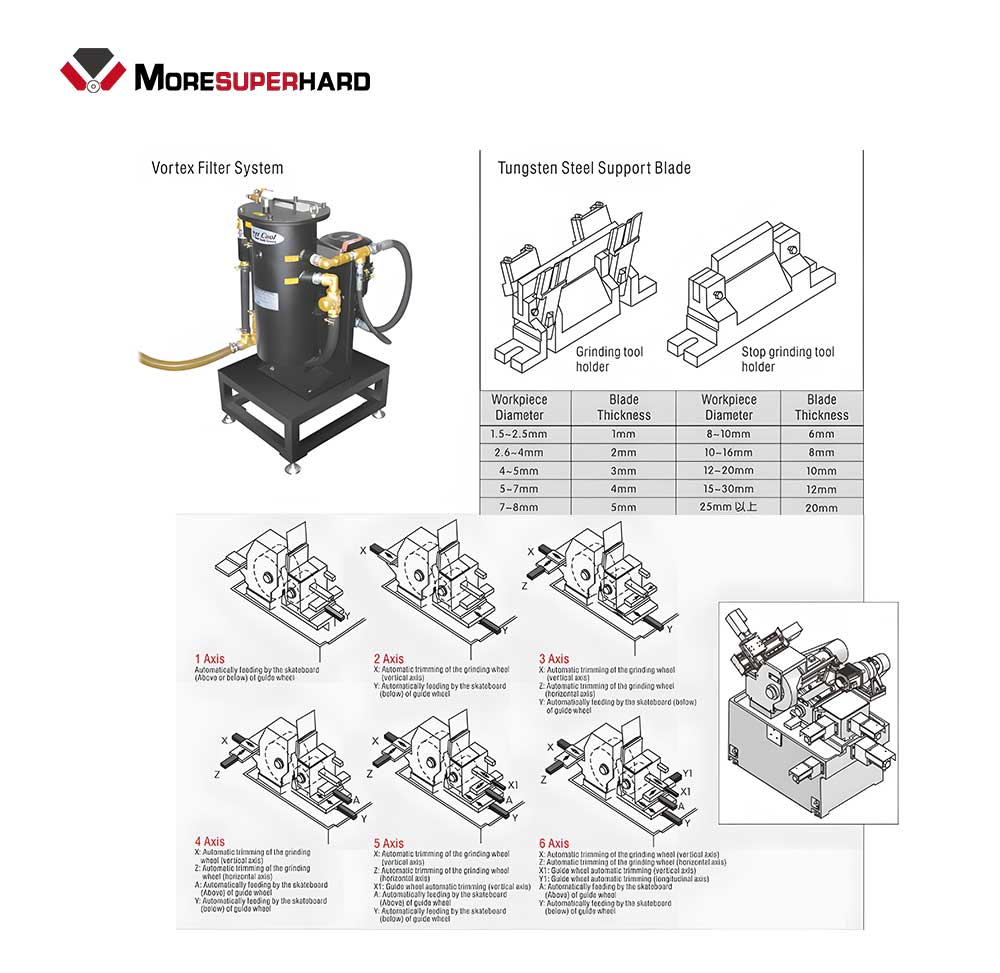

What are the methods of centerless grinding?

There are two main grinding methods for centerless cylindrical grinders: through type and plunge type; through type centerless grinder, the workpiece is fed along the axis of the grinding wheel for grinding, and the small inclination angle of the guide wheel axis is adjusted to realize the axial feed of the workpiece. It is suitable for grinding slender cylindrical workpieces, short shafts without central holes and sleeve workpieces. The plunge-type centerless grinding method is that there is an axial positioning fulcrum on the pallet, the workpiece is supported at a certain position on the pallet, and the grinding wheel or guide wheel is used for grinding. For grinding workpieces with shoulders or bosses as well as cones, spheres or other workpieces of revolution. “Plung-in” to “Through-through” centerless grinding is a composite grinding method of the two centerless grinding machines.

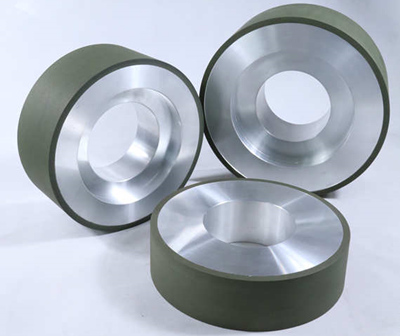

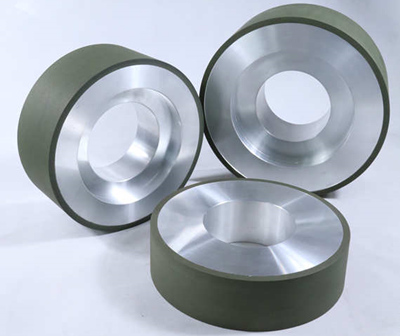

Moresuperhard Centerless Diamond Grinding Wheel - Resin Bond

► Application: grinding carbide, ceramic, magnetic materials, stainless steel bar, PCD & PCBN compositives

► Model: 1A1 , 6A1, 9A1

► Bonded Type: Resin bond, Metal bond

► Centerless Grinder Machine: Koyo, Crystec, Dedtru, Landis , Okuma, Paragon, Royal Master, Unison, WMV

.jpg)