Optimized for Mold, Aerospace, and Medical Component Manufacturing

Case Overview

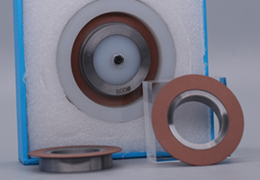

This technical case study demonstrates the successful application of specialized metal and resin bond CBN wheels on the HAUSER H55-400 jig grinder. The solution achieves micron-level precision for mold steel workpieces, serving high-demand industries such as aerospace, medical devices, and automotive manufacturing.

Technical Specifications

| Parameter |

Specification |

| Grinder Model |

HAUSER H55-400 |

| Worktable |

1440 × 860 mm |

| Load Capacity |

800 kg (peak 1500 kg) |

| T-Slots |

7 slots (14 mm) |

| Power Supply |

400 V / 50 Hz, 9 kW total |

| Grinding Wheels |

Resin Bond & Metal Bond CBN |

| Workpiece |

Mold Steel Components |

Key Achievements

-

Ultra-Precision Grinding:

-

Exceptional surface finish and dimensional accuracy for complex geometries.

-

Ideal for molds, aerospace components, and medical instruments.

-

Dual Bond Flexibility:

-

Efficiency Optimization:

Applications

-

Precision Molds: Injection molds, die-casting molds, and stamping dies.

-

Aerospace: High-complexity components requiring tight tolerances.

-

Medical Devices: Surgical tools and implants with stringent surface finish requirements.

-

Automotive: Core components such as engine parts and transmission elements.

Why Choose This Solution of CBN and Metal Grinding Wheels?

-

Proven Performance: Validated on Swiss-engineered HAUSER grinders for reliability.

-

Technical Support: Custom wheel configurations based on material and application needs.

-

Global Supply Chain: Rapid delivery and after-sales service across 30+ countries.

Contact Us

Elevate your jig grinding capabilities with our CBN wheel solutions. Request a technical consultation or free grinding test:

Email: [email protected]

Whatsapp: +8619900915906

https://www.mogrinding.com/

https://machinery.moresuperhard.com/