Introduction of Resin Bond Diamond Wheel for Polishing Carbon Parts:

In the competitive world of carbon part manufacturing, obtaining flawless finishes is crucial. This customer case delves into the success story of a leading carbon part manufacturer who achieved remarkable results using our Resin Bond Diamond Wheel. By adhering to the principles of efficiency, reliability, and quality polishing, our product has become an invaluable asset in their production processes.

Customer Background of Resin Bond Diamond Wheel for Polishing Carbon Parts:

Our customer, specializes in producing high-quality carbon parts for various industries such as automotive and sporting goods. Their commitment to excellence has established them as a trusted supplier within the market. However, they faced a significant challenge: finding a polishing solution that could consistently deliver impeccable finishes while maintaining the structural integrity of carbon parts.

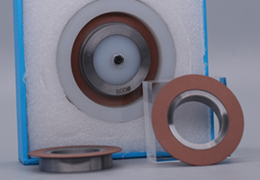

Moresuperhard Resin Bond Diamond Wheel is an innovative and cutting-edge product designed specifically for polishing carbon parts. This solution provided numerous advantages that aligned perfectly with their requirements. The Resin Bond Diamond Wheel excelled in the following areas:

Superior Polishing Performance:

Our Resin Bond Diamond Wheel employed advanced diamond technology, ensuring exceptional polishing performance. The carefully formulated resin bond maximized the wheel’s ability to remove imperfections, resulting in a flawless finish on carbon parts.

Precision and Consistency:

By leveraging the resin bond’s remarkable hardness and strength, CarbonTech Solutions achieved consistent polishing results across all their carbon parts. The wheel’s precise abrasive properties allowed for targeted polishing of intricate areas, guaranteeing superb surface quality.

Durability and Cost Efficiency:

The Resin Bond Diamond Wheel demonstrated superior durability, offering an extended lifespan compared to traditional polishing methods. This longevity resulted in reduced downtime and increased overall cost efficiency for CarbonTech Solutions.

Streamlined Workflow:

The efficient design of our Resin Bond Diamond Wheel significantly reduced polishing time, enabling CarbonTech Solutions to meet tight production deadlines and handle larger order volumes. This streamlined workflow enhanced their overall competitiveness and customer satisfaction.

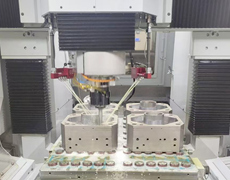

Detailed Information of Resin Bond Diamond Wheel for Polishing Carbon Parts:

Wheel Size: Diameter 620mm

Wet / dry: Dry fine grinding

Process material : Carbon graphite

Typical Workpiece size: Ø80ODx35IDx5 mm thickness

Material removal required : 0.05 mm (Cumulative of both sides)

No of pieces per carrier :3

No of carriers in a set : 5

Surface finish requirements: Bottom side: Ra0.8

Top side: Ra0.2

Flatness requirements: Less than 1 micron

Other requirements: Ground surface must be free from scratch marks / Line marks

Results of Resin Bond Diamond Wheel for Polishing Carbon Parts:

With our Resin Bond Diamond Wheel as their go-to polishing solution, our customer achieved impressive results. The consistent and flawless finishes generated by the wheel elevated the quality of their carbon parts, reinforcing their reputation as a top-tier manufacturer. Moreover, the integration of our product improved their overall operational efficiency, enabling them to scale their production and meet the growing demands of their customers.

---EDITOR: Sarah Shi,Jackie Wang

---POST: Jackie Wang