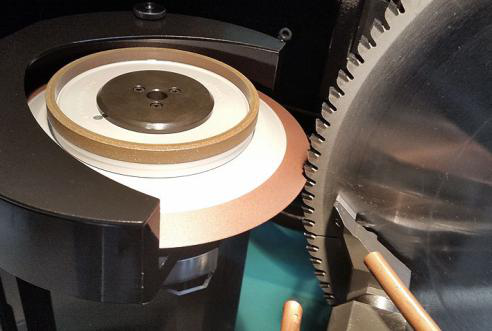

Recently, Moresuperhard earned a feedback of a customer from Russia, St. Petersburg city. He ordered 1A1 diamond grinding wheel for carbide grinding few days ago and give us the feedback at once after using!

Let's have a look at the customer's feedback about our products!

The details of this feedback are below:

Dear Moresuperhard,

Hello, we are a company from Russia, St. Petersburg city. We recently

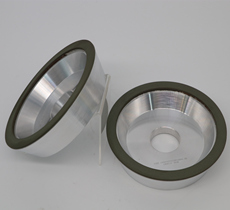

ordered a diamond wheel from you for grinding carbide:

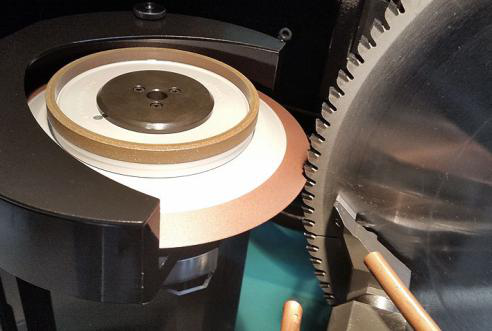

shape 1A1,

diameter 250mm, bore diameter 32mm. These wheels worked well

and we want to order 2 more wheels 250mm and 2 wheels of the

same, but with a diameter of 200mm. There are 4 wheels in total.

Best Regards,

...................

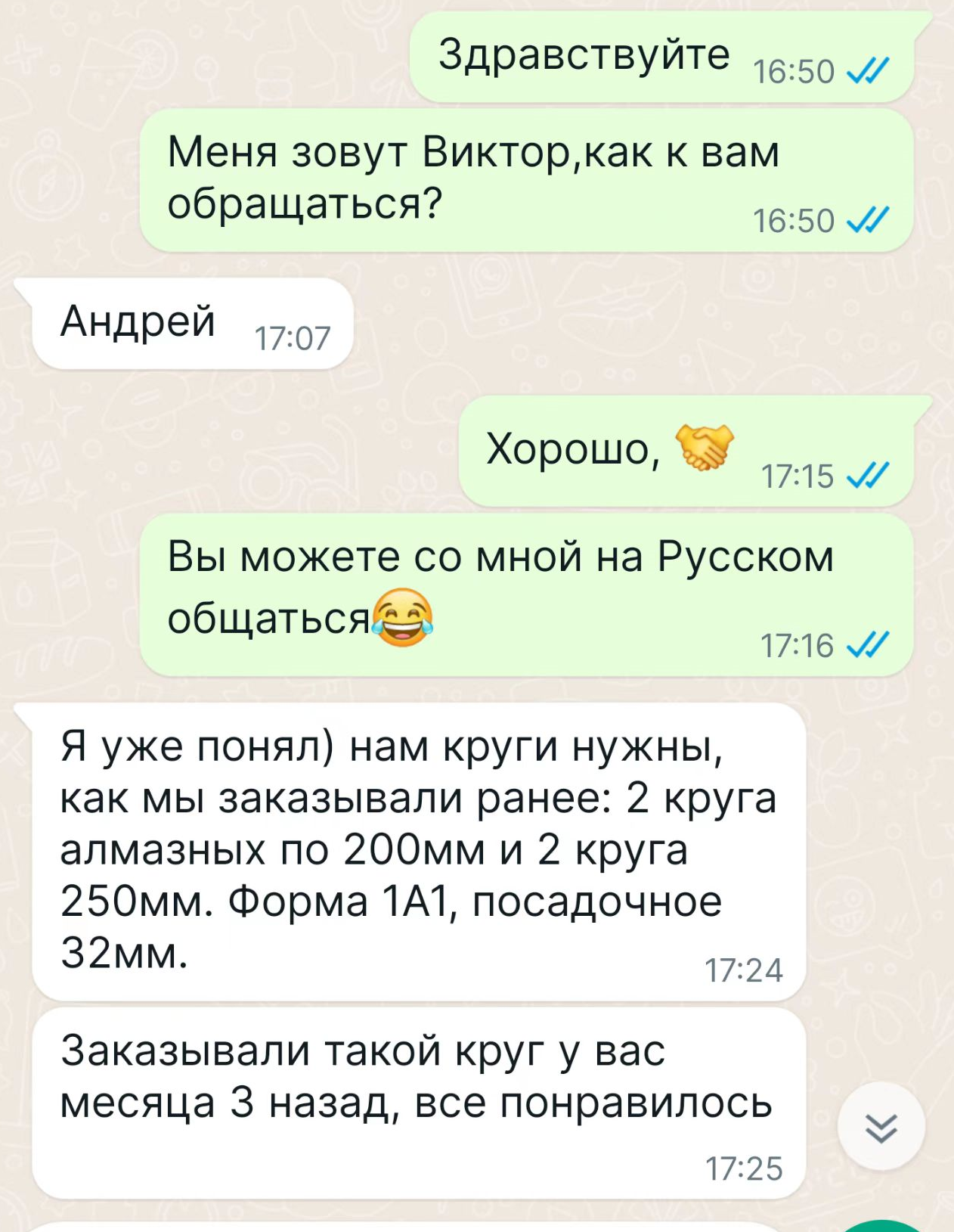

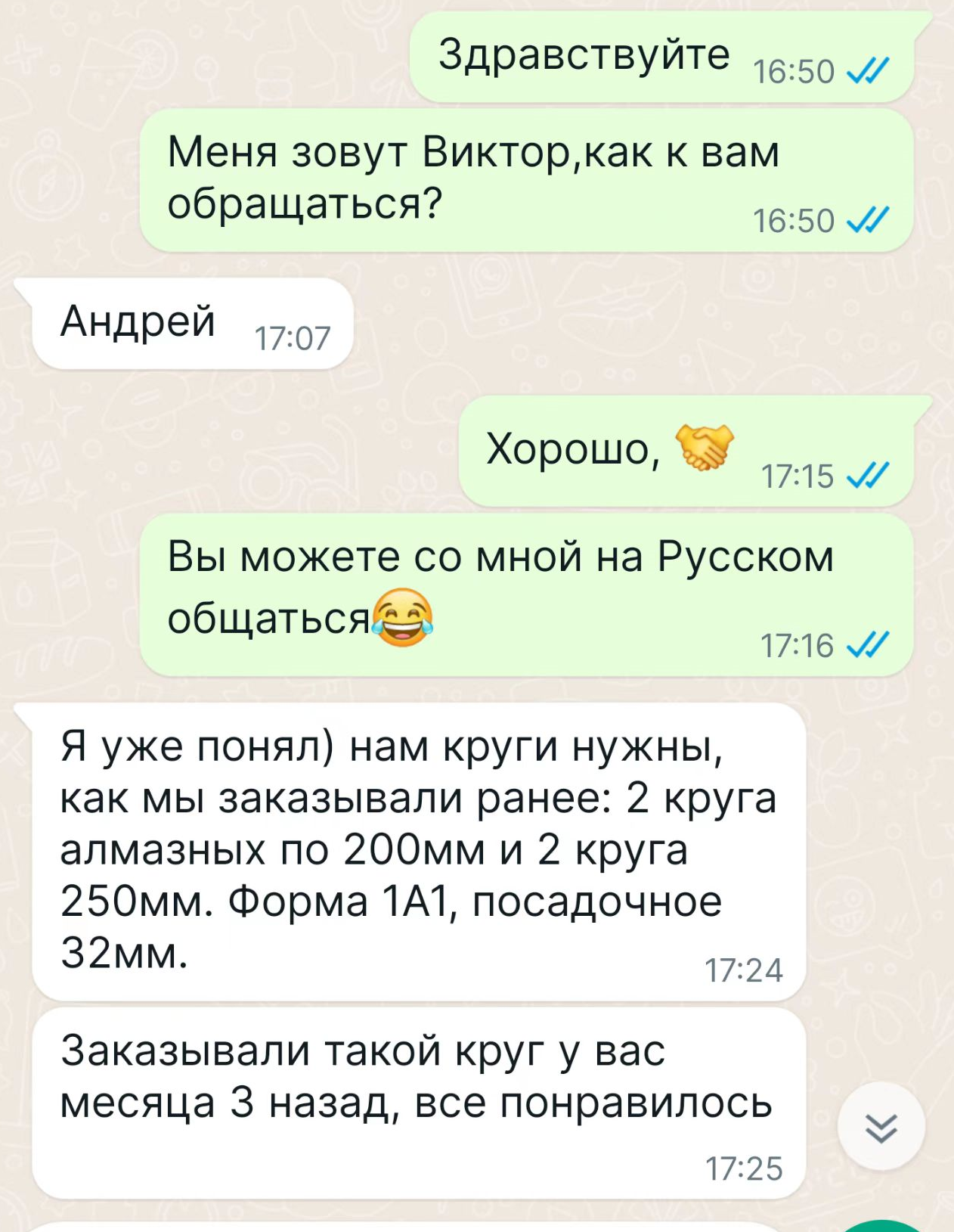

Besides, he also chatted with our sale to express his recognition and gratitude through WhatsApp:

We really appreciate customer's feedback which will inspire us to move forward and dedicate to making more progress in grinding products!

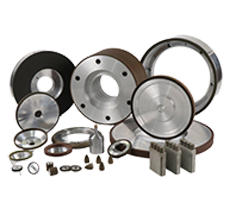

What are the applications of vitrified diamond grinding wheels?

♦ For tungsten carbide workpieces

♦ Steel based tungsten carbide coating workpiece

♦ Non-metallic materials semi-finishing grinding and finishing grinding, etc.

Models: 1A1(Diameter: 100mm-1200mm)

What are the advantages of vitrified diamond grinding wheels?

What are the advantages of vitrified diamond grinding wheels?

♦ The bonding strength of vitrified bond to grinding is better than resin bond

♦ After customized diamond grinding tools with higher diamond concentration, it is less heat and jam generate in grinding

♦ High grinding efficiency

♦ Very sharp grinding

♦ Long lifespan and easy to dress

What are the applications of resin bond diamond grinding wheel?

Resin bond diamond grinding wheel is grinding tungsten carbide cutting tools, ceramic , magnetic materials, silicon , sapphire, glass , quartz and HVOF carbide coated,PCD, PCBN, etc

Applicable Industry: carbide inserts (cnc tools), carbide circular saw (woodworking tools), Thermal Spraying Coated, Silicon Wafer Grinding, etc

Model: 1A1R, 1A1, 3A1, 1V1, 4A2, 4BT9, 6A2, 11V9, 12A2, 14F, etc

Advantages of resin diamond grinding wheel

Advantages of resin diamond grinding wheel

* High cutting efficiency, good self-sharpening, less blocking, reducing the grinding burn occurs when the phenomenon of work

* Good flexibility will help to improve the surface roughness, mainly used for rough grinding, semi-fine grinding, polishing and other processes

* Compared to conventional silicon carbide , resin diamond wheel has good material removal rates, longer wheel life and lower grinding costs

* Resin bond diamond wheels generally remove material up to 10 times faster than metal bond wheels

With a global development strategy and comprehensive multilingual business departments, Moresuperhard keeps an eye on the latest developments in the global grinding industry and is committed to providing high-quality and efficient grinding products and services to our customers worldwide! We also accept customized orders to suit your needs.

If you have any questions about Internal Grinding Wheel for Inner Face of Gears, please feel free to contact us! You can leave us your questions below, and we will contact you as soon as possible!

---EDITOR: Victor Liu,Jackie Wang

---POST: Jackie Wang

.png)

.png)