Moresuperhard attended CIMT2023 Beijing last week, and we gained a lot from this event for the digital intelligence era, the global industry and the deep integration of upstream and downstream industry chains! The six-day Beijing Machine Tool Show came to a successful end on April 15, 2023.

The exhibition area of United Grinding left a deep impression on us. The United Grinding Group integrated intelligent and digital technology elements into the on-site display around the innovative concept, combining industrial manufacturing with enthusiasm, openness, and integration. In the six days, it was a fabulous feast worthy of praise, collection and forwarding.

United Grinding maintains a leading position in the market and technology in various aspects of grinding technology and all related industries. To achieve this goal, United Grinding focuses on three strategic directions: innovation, localization, and customer orientation. These three factors are closely connected. Innovation refers to the development of innovative and high-quality products based on customer needs and requirements; localization means establishing a stable and competitive supply chain domestically, taking into account every stakeholder (customer, supplier, employee, society, etc.); Customer orientation "refers to everything we do to make customers' lives and work easier.

Mr. Erwin Geissler, CEO of United Grinding, introduced the CIMT exhibition area of United Grinding to everyone. The United Grinding Group showcased a revolutionary customer-oriented innovation - the C.O.R.E. operating system. C. The O.R.E. operating system not only endows various brands of machine tools in the United Grinding Group with a unified operating interface, enabling easy data exchange. The integrated umati interface can also communicate with third-party systems, laying a technical foundation for customers to achieve digital manufacturing. In addition, adhering to the role positioning of "the leader in the cutting tool industry", Mr. Erwin Geissler stated that United Grinding will continue to maintain or even expand the gap with peers through sufficient research investment.

The tool grinding brands WALTER and EWAG of United Grinding are widely known in the industry, with many loyal fans. Their excellent machining experience has never been disappointing. Mr. Erwin Geissler stated that ensuring stable or even continuous improvement in quality over many years or even decades is more of a process of positive development. WALTER and EWAG, like all brands of the United Grinding Group, have been fighting for quality for a long time. This time, we mainly introduce three products that are particularly suitable for the Chinese market: COMPACT LINE/HELITRONIC G200 and HELITREC NANO.

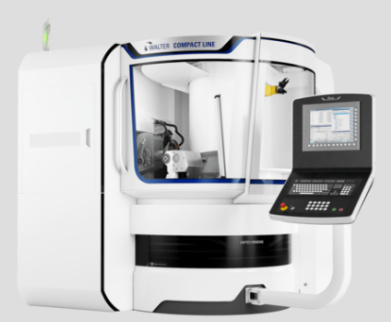

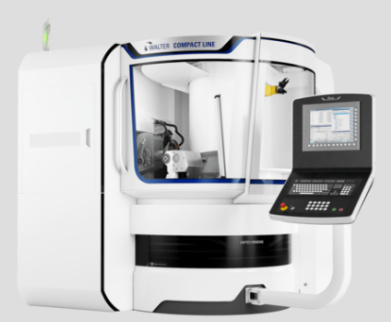

COMPACT LINE CNC blade grinding machine

This equipment is equipped with 6 CNC axes and can be used for the processing and production of indexable blades such as cutting, milling, turning, and forming blades. This model supports various clamping systems and can be added through a plug and play interface, providing ample freedom for your tool, order, and batch selection. Thanks to minimal setup time, even small batches can be produced economically.

HELITRONIC G200

This equipment is equipped with 6 CNC axes and can be used for the processing and production of indexable blades such as cutting, milling, turning, and forming blades. This model supports various clamping systems and can be added through a plug and play interface, providing ample freedom for your tool, order, and batch selection. Thanks to minimal setup time, even small batches can be produced economically.

HELITRONIC G200

This equipment has an innovative machine tool concept and was developed for the first time by WALTER in collaboration with the German Chinese project team. It is economical and efficient, covering an area of less than 2.3 square meters, but can achieve the best tool grinding. It produces and regrows rotating symmetric tools with a diameter range of 1-125 mm, a maximum length of 235mm, and a maximum weight of 30kg

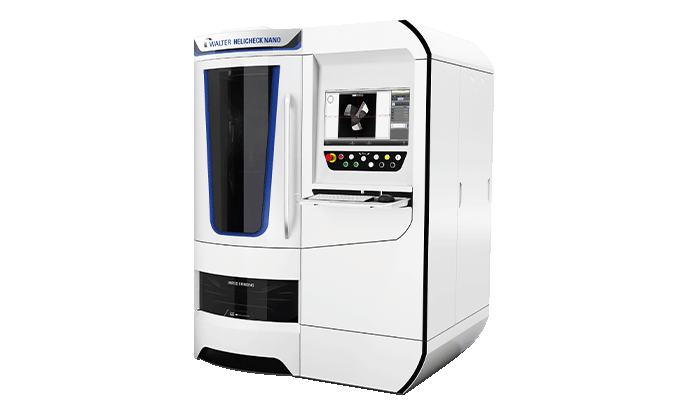

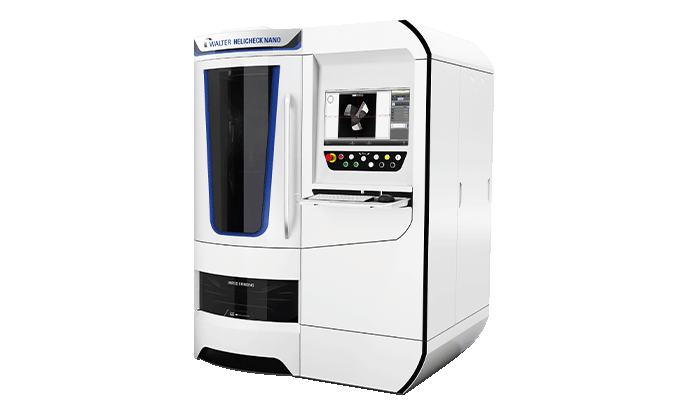

HELICHECK NANO measuring machine

This equipment has an innovative machine tool concept and was developed for the first time by WALTER in collaboration with the German Chinese project team. It is economical and efficient, covering an area of less than 2.3 square meters, but can achieve the best tool grinding. It produces and regrows rotating symmetric tools with a diameter range of 1-125 mm, a maximum length of 235mm, and a maximum weight of 30kg

HELICHECK NANO measuring machine

WALTER can provide a non-destructive and independently operated product measurement solution for micro and nano tool manufacturers, reliably measuring tools with a diameter of 0.1 millimeters under transmitted and reflected light. Moreover, it provides the possibility of automation without operator intervention, and can automatically measure pallets of up to 7500 tools overnight. In the future, the device will also expand more functions, such as measuring cutting edge fillets, 3D digitization, and measuring surface smoothness.

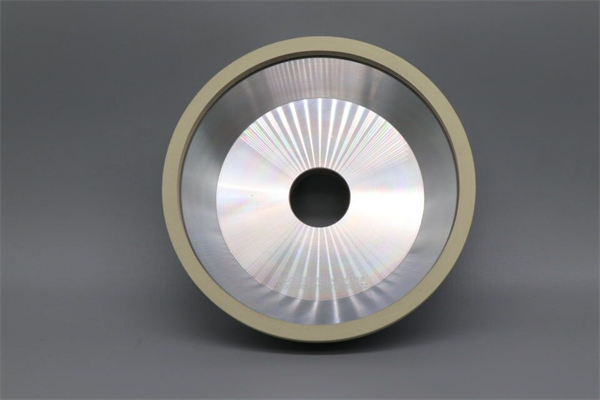

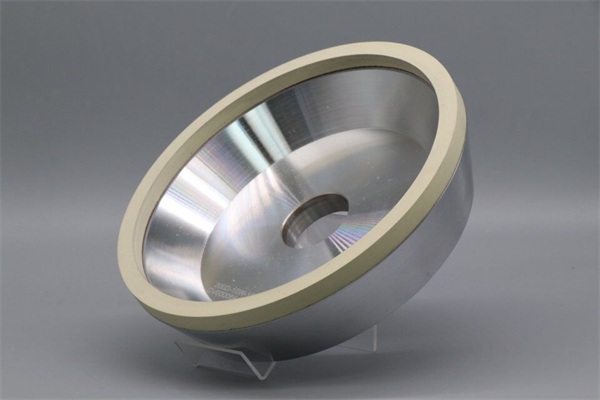

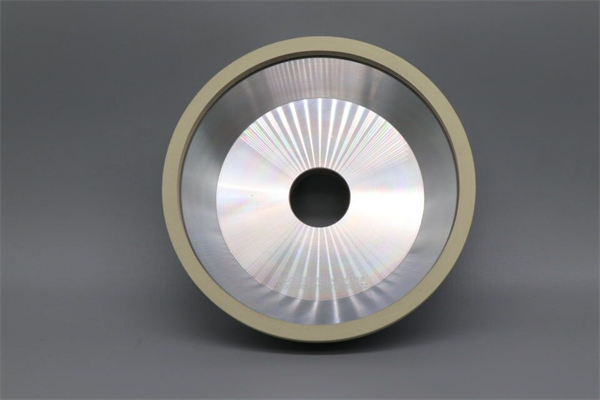

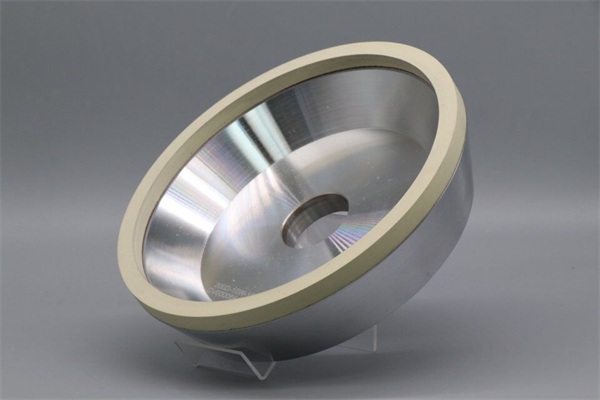

Vitrified Diamond Wheels Application Case of EWAG Compact Line:

WALTER can provide a non-destructive and independently operated product measurement solution for micro and nano tool manufacturers, reliably measuring tools with a diameter of 0.1 millimeters under transmitted and reflected light. Moreover, it provides the possibility of automation without operator intervention, and can automatically measure pallets of up to 7500 tools overnight. In the future, the device will also expand more functions, such as measuring cutting edge fillets, 3D digitization, and measuring surface smoothness.

Vitrified Diamond Wheels Application Case of EWAG Compact Line:

The

COMPACT LINE CNC insert grinding machine is equipped with 6-axes. It can be used for the production of indexable inserts such as cutters, milling tools, turning tools and forming inserts. This model supports a wide range of clamping systems and can be retrofitted via a plug-and-play interface, offering full freedom in your tool, order and lot selection. Thanks to the minimal setup time, even very small batches can be produced economically.

Processing Details:

Wheel size : 11A2-Ø200-W10-X10-H40

Wheel grit: D16 C125

Wheel speed :12M/S~30M/S

Machine: EWAG Compact line

Press:feed on pressure at 130-140 Nm

coolant:Oil

Workpiece: PCD inserts

Work life: 0.07mm/plate

Application Of Vitrified Peripheral Diamond Grinding Wheels

Mainly used for precise edge grinding of indexable inserts (such as tungsten carbide inserts, ceramic inserts, CBN inserts).

Materials of workpiece: tungsten carbide, ceramics, metal ceramic PCD/ PCBN inserts, etc.

Model: 6A2T, 6A2M, 11A2B, 12A2T (or full customed )

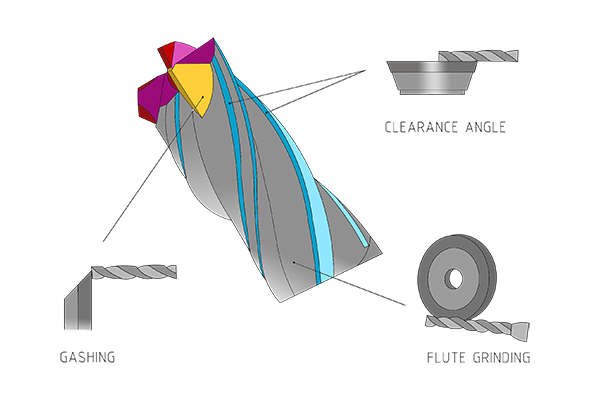

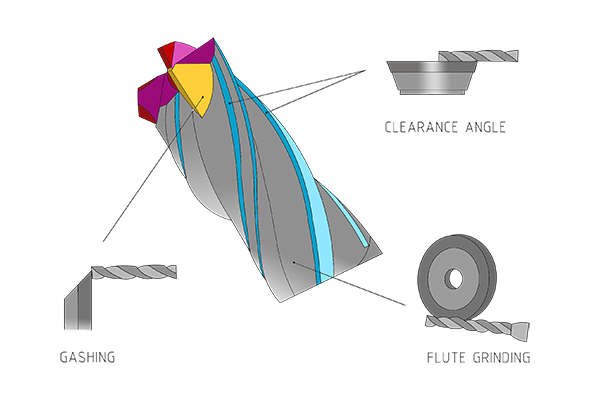

Diamond CBN Grinding Wheel for Walter CNC Five-axis Machines:

► Application: grinding carbide and HSS. (such as drill, end mill, reamer)

► A complete solution for CNC tools manufacturing: fluting, gashing and Clear edge, relief angle grinding, OD grinding

► Model: 1A1, 1V1, 11V9, 12V9, 14A1, 12V5, etc (or full customed )

.jpg)