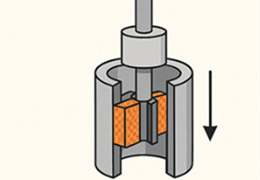

The purpose of grinding as the finishing step is to obtain the surface quality which cannot be achieved by hard machining. Shaft products require high surface quality of bearing mounting position or sealing position. For example, some surfaces require a non-helical surface, which is not possible with hard cars. Some parts are severely discontinuous, and turning can be a quick way to remove the margin. The precision grinding process is then used in the same clamping process in order to precisely grind to the required size and surface quality. Because the margin of grinding after hard lathe machining is very small, the grinding wheel wears lightly, which can reduce the dressing times and improve the processing efficiency.

Hard machining removes most of the allowance. Grinding allowance is very small and uniform. Grinding is only used as the final finish to improve efficiency, On the other hand, the high metal removal rate of hard cars is also the improvement of efficiency. Hard turning can also be used to process threads and grooves. By increasing the grinding process, more accurate overall results can be obtained. The foundation of the success of composite machining process is to understand the correct process knowledge of hard wheel and fine grinding and the interaction between these two processes, then can achieve efficient and stable production, can produce high profile and dimensional accuracy, and high surface roughness requirements of parts, also it can prolong the tool life and reduce the use cost.

More Superhard can supply not only turning tools, but also grinding wheel. Contact us for more detailed information.