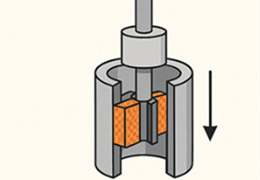

The grinding mechanism is completely different with cutting.

In cutting,using the tool cut into workpiece material so the material deforms then breaks.

The surface of the workpiece is squeezed and rubbed by the tool to make the material tear from the workpiece, so there are microscopic defects after processing;

The friction and extrusion of the tool on the machining surface and the surface stress between the workpiece and the tool are the factors that affect the precision of the workpiece in the machining process.

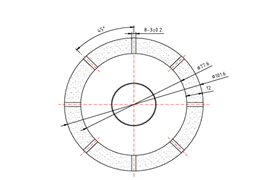

Grinding processing accuracy is higher than turning and milling, mainly show in the processing of high hardness materials. grinding workpiece surface by abrasive delimit engraved with extrusion, Diamond/CBN grain sizes will be fall off and the grinding speed is very high, so in a short period of time will have a lot of grits strokes on the surface of the inscription that improve the quality of surface, grinding grain will force loss after the dull due to the cutting face bigger .

The exfoliated abrasive particles have little influence on the surface quality, and the abrasive particles vary in size, so different grinding wheel particle sizes can be selected according to your needs.