How to grind the Monocrystalline silicon in integrated circuits?

Monocrystalline silicon, which is used to make integrated circuits, often requires polishing of the positioning surfaces. This means that one or two flat surfaces are polished on the side of the crystal bar, along the longitudinal direction of the crystal. Polysilicon is polished on two planes, one wider, called the primary orientation plane, and the other narrower called the secondary orientation plane. The orientation and position of the positioning surfaces are strictly defined. (For (111) crystals the primary positioning plane is the (1-10) plane and for (100) crystals the primary positioning plane is the (011) plane. Photovoltaic crystals or small square ingots are polished on four planes to ensure that there are no cut marks on the four planes, a mirror effect is required and in practice, the grinding product needs to be selected according to the process requirements.

What kind of vitrified grinding wheel can you use to grind monocrystalline silicon?

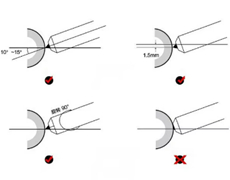

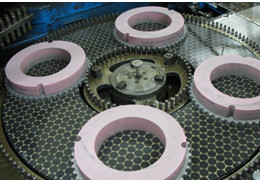

The grinding of the positioning surfaces is carried out on a roller mill. During operation, the crystal does not rotate and the crystal or the grinding head moves longitudinally. Currently, depending on the capacity requirements, the machine is designed with two or three face grinding wheels and two rods are coarsely and finely ground at the same time to increase capacity.

The earliest crystals that have undergone tumbling and polishing of the positioning surface must then be chemically etched and polished to remove the mechanically damaged layer on the surface of the crystal, which is also done for semiconductors. This process is now used in the PV industry for ultrasonic cleaning and goes directly into the sticky bar room for a sticky bar and curing treatment, followed by cutting to complete the silicon wafer manufacturing process.

Depending on the changing market, the technology for polishing monocrystalline silicon is constantly being updated and the requirements of this process are constantly being upgraded, along with significant changes in yield and quality.

Moresuperhard welcome all those in the industry to share their views. If you have any questions would like to ask, please contact us online or leave a message.

---EDITOR: Jackie Wang

---POST: Jackie Wang