How to install and operate one Polishing Film Machine?

Snorkel installation of Polishing Film Machine

Snorkel installation of Polishing Film Machine

1, prepare an air compressor (the volume of the gas tank is about 90L, the flow rate is 580L/min, the exhaust pressure is 0.7MP left

Right)

2, prepare a gas pipe (diameter 8mm)

3.Open the electrical cabinet door and connect the air pipe to the vent, as shown in the following figure

4. After the gas pipe is connected, the other end of the gas pipe comes out from under the electric box and passes to the outside

5. Prepare a gas pipe interface (used to connect the air compressor interface), installed on the gas pipe outside the electric box (if the air pressure machine

The diameter of the gas pipe interface is inconsistent with the diameter of the gas pipe interface of the electrical box, and a converter is required.

6. Open the air compressor, the barometer above the panel of the mirror electrical box begins to rotate, and the pressure adjustment button is rotated to adjust the air pressure

7. The air conditioning work is completed

Lathe Installation of Polishing Film Machine

1. prepare a base (base size: measure the center height of the lathe, and then make the height of the base according to the center height,

Base length and width according to the length and width of the mirror machine), the position of the screw hole connected to the lathe under the base should be determined

The base seat can be fixed on the lathe tool holder

2. Connect the mirror machine with the base with screws, remove the lathe tool holder, and install the base in the original position of the tool holder

3. Observe whether the rubber wheel of the mirror machine and the workpiece are parallel, if not parallel, fine tune the position of the base until parallel

4. tighten the screws under the base, the mirror machine is completely fixed on the lathe

5. Lathe installation completed

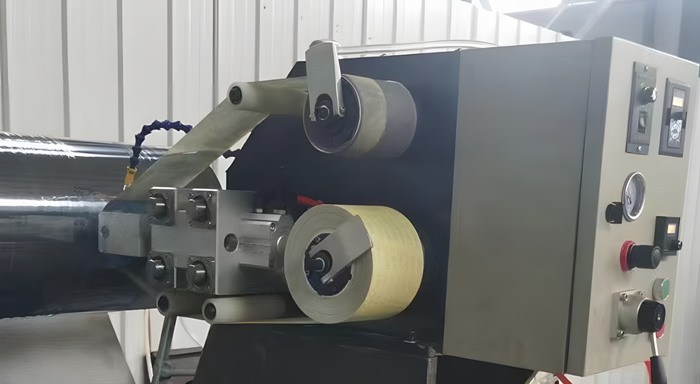

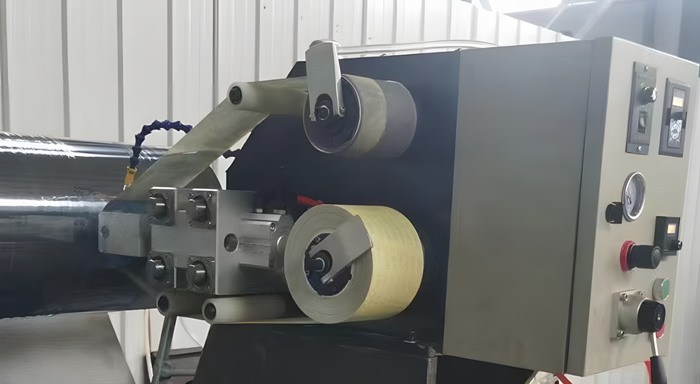

Polishing Debugging of Polishing Film Machine

1. Install the sand belt on the machine, reel it above, and roll it below.

2. Electrify and ventilate the mirror machine, shake the lathe handle, and slowly push the mirror machine close to the workpiece

3. Click the green switch button, and then rotate the swing frequency button, adjust the vibration frequency of the mirror machine (vibration frequency according to

Process to determine)

4. Adjust the pressure of the mirror machine, rotate the pressure button (generally between 0.2-0.6MP)

5. Water, mirror polishing for wet polishing, polishing process can not stop the water, small water can be

6. Push the mirror machine to the workpiece 1 cm away, flip the cylinder ejection switch (to the right), the cylinder ejection,

Rubber wheel against the workpiece, began to swing polishing

7. According to the requirements, decide the different granularity of abrasive belt polishing back and forth times, abrasive belt from coarse to fine replacement polishing, to mirror effect

8. Polishing and debugging work is completed

Mirror polishing machine parameters

Maintenance

1, the vibration head part of the machine, regularly add lubricating oil on the four shafts

2. When the machine works for a long time, there will be abrasive residue attached to the vibrating head. Clean the vibrating head regularly

3. Wipe the machine regularly to avoid dust entering the machine