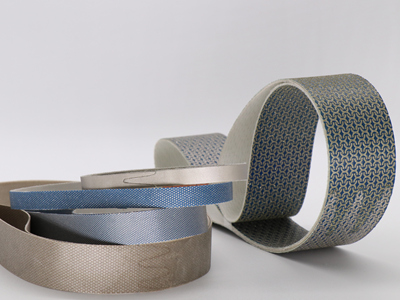

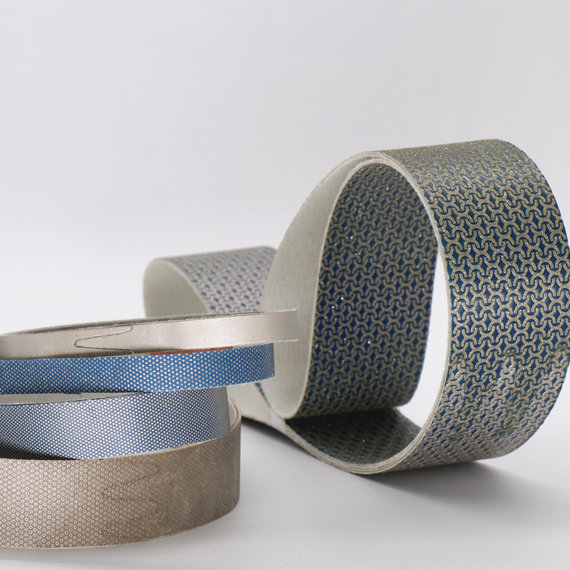

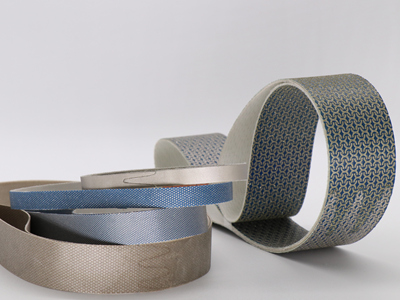

Applications of diamond and cbn sanding belts

Diamond & CBN sanding abrasive belt can be widely used for grinding steel, stone, glass, ceramics, monocrystalline silicon, polysilicon, zirconia, alumina, metal-nonmetallic synthetic materials, cemented carbide, aluminum-magnesium alloy, aluminum beryllium alloy, titanium alloy and etc. hard brittle materials.

Classification of Diamond Sanding Belt

Bond: Diamond sanding abrasive belt is divided into metal nickel plating electroplated bond and resin bond, a resin bond also consists of flexible and hard type.

Pattern: There are many grinding advantages such as sharpness, durable, flexible, dry or wet grinding for diamond sanding abrasive belt with various patterns. Please choose different design patterns according to needs.

Backing Base: The main characteristics of the backing are thickness, softness, temperature resistance, and easy quickly removal. Select the backing base according to the material which will be ground.

► Electroplated Bond Diamond Abrasive Belt

.jpg)

► Resin Bond Diamond Abrasive Belt

Customer Case

Customer Case

Moresuperhard's customer previously used Kegis abrasive belts, which were of good quality, but the customer thought they were slightly overpriced. In order to reduce the processing cost, he tried other domestic brands of diamond belts in China, after testing and using but they could not meet his requirements.

Later, the customer found our website, and after some professional communication between us, the customer expressed his willingness to try to test our resin CBN abrasive belts. After several tests and uses, the customer provided good feedback on the use. He thought Moresuperhard's abrasive belts were very soft and especially suitable for polishing their steel knives, and expressed that he would continue to have a relationship with Moresuperhard.

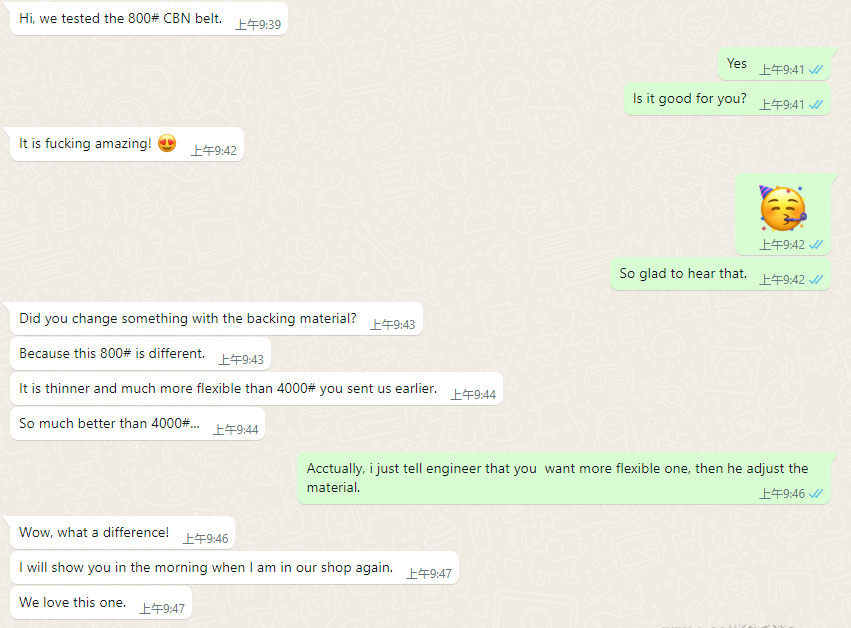

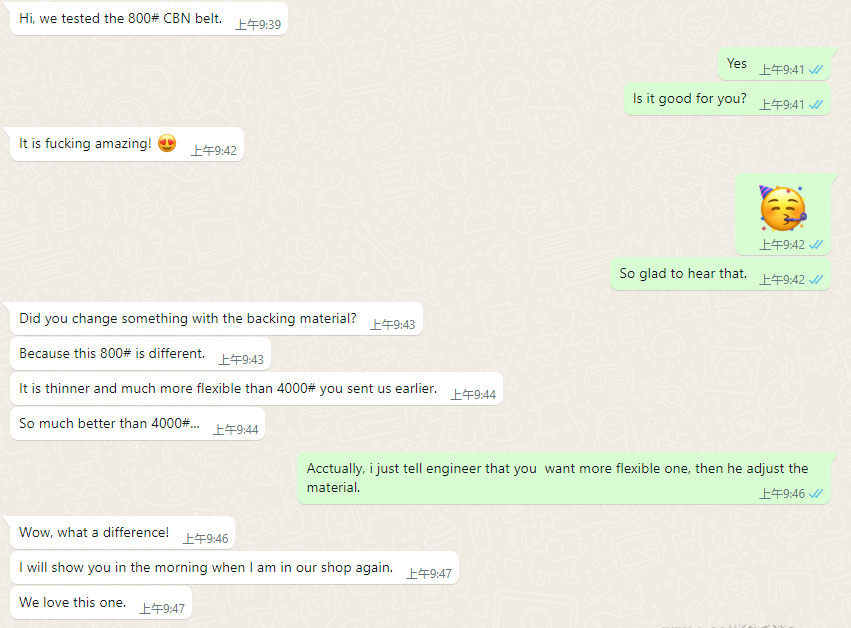

Here is the customer's feedback after testing and using our resin diamond sanding belt size 50x1500mm 4000# and 50x1500mm 800#:

.png)

He firstly made a purchase of our diamond sanding belt #4000, but he found that it was a little stiff. Because we have the ability to provide customized services for customers and our engineer made some improvements for his workpieces, so the second time he purchased the belt, he found the test and use result was amazaing!

.jpg)

.jpg)

.png)

_(1).jpg)