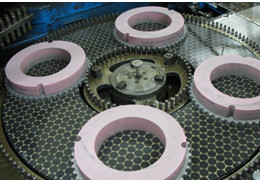

Metal diamond grinding wheels are commonly used for grinding glass bottles in industrial applications. They consist of a metal bond matrix with diamond particles embedded within the matrix. The metal bond provides excellent durability and resistance to wear from the abrasive glass surface while the diamond particles allow for a precise and efficient grinding process.

When using metal diamond grinding wheels for grinding glass bottles, it is important to choose the appropriate grit size. A finer grit size will provide a smoother surface finish while a coarser grit size will remove material faster. Additionally, the diamond concentration, or the number of diamond particles per unit area, can also be adjusted for different grinding applications.

It is important to note that proper safety precautions should always be taken when using metal diamond grinding wheels for grinding glass bottles, including the use of personal protective equipment such as safety goggles and gloves. Additionally, the grinding process should be performed with adequate ventilation to prevent the inhalation of glass dust and other particles.

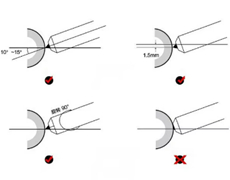

The steps to follow when using a metal diamond grinding wheel to grind the edge of a glass bottle:

1. Secure the glass bottle: Before grinding, make sure that the glass bottle is secured in place to prevent it from moving or vibrating during the grinding process. You can use clamps or a specialized holding device designed for glass bottles.

2. Select the appropriate grinding wheel: Choose a metal diamond grinding wheel with the appropriate grit size and diamond concentration for the type of glass bottle you are grinding. Consult the supplier or manufacturer for recommendations.

3. Wear protective gear: Wear safety goggles and gloves to protect your eyes and hands from glass particles and flying debris.

4. Start grinding: Holding the glass bottle securely, slowly lower the edge onto the grinding wheel, starting from one end of the edge and working your way to the other end. Apply a moderate amount of pressure and maintain a constant speed to ensure an even grind.

5. Check progress frequently: It is important to check the progress frequently to avoid overheating or damaging the glass bottle. Use a piece of cloth to wipe away any glass dust or debris that collects on the grinding wheel.

6. Smooth the edges: Once the desired shape has been achieved, use a finer grit size grinding wheel to smooth out the edges of the glass bottle for a polished finish.

7. Clean up: When finished, thoroughly clean the glass bottle and the grinding wheel to remove any debris or dust.

Here are some additional features of metal diamond grinding wheels for grinding glass bottles:

►High Efficiency: Metal diamond grinding wheels are very efficient for grinding glass bottles due to the use of diamond particles, which are extremely hard and can remove material quickly and precisely.

►Long Lifespan: Due to their metal bond matrix, metal diamond grinding wheels have excellent durability and can last for a long time even with frequent use.

►Wide Range of Applications: Metal diamond grinding wheels can be used for grinding a variety of glass bottles with different shapes, sizes, and thicknesses.

►Consistent Performance: Metal diamond grinding wheels are designed to provide consistent performance over time, ensuring that the surface finish is uniform and of high quality.

►Low Maintenance: Metal diamond grinding wheels require minimal maintenance and can be easily cleaned and maintained between uses.

►Versatile: Metal diamond grinding wheels can also be used for other materials, such as ceramic and stone, making them a versatile choice for industrial grinding applications.

Moresuperhard Customer Case of M

etal Diamond Grinding Discs to Grind the Edge of Glass Bottles:

The feedback details are as the follows:

"I recently purchased a set of metal diamond grinding discs to grind the edge of glass bottles for a personal project. I was impressed by the high efficiency and consistent performance of the grinding discs. They made the grinding process quick and easy, and I was able to achieve a precise and uniform edge without any chipping or cracking.

The grinding discs were also very durable and have held up well to frequent use. The metal bond matrix with embedded diamond particles was especially effective in removing material quickly and precisely without causing any damage to the glass surface.

I appreciated that the supplier provided recommendations regarding grit size and diamond concentration based on the specific type of glass bottles I needed to grind. This guidance was crucial in ensuring that I get the best possible results."

Overall, our custormers are very satisfied with their purchase of the metal diamond grinding discs, and would recommend them to anyone looking for an efficient and reliable solution for grinding glass bottles.