The Introduction of Glass Molding Grinding:

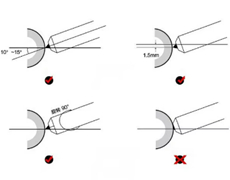

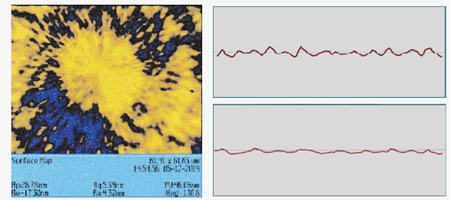

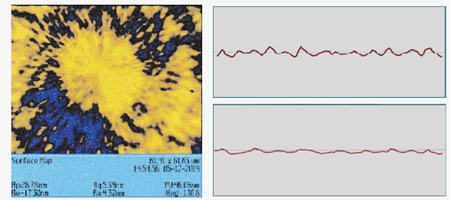

The glass molding method does not process the lenses themselves, but rather the molds used in the production of the lenses. The materials used are Cemented Carbide and CVD-SiC, and the dimensional accuracy is strictly required. Cemented carbide is a kind of powder sintered material, while silicon carbide of CVD process is a kind of material with compact structure, using tiny tools to fix the abrasive for precision machining, it can achieve the dimensional accuracy and surface roughness required by aspheric lenses, no matter what kind of material is used, if only precision grinding is carried out, it will leave machining traces in the center of the workpiece, and if the machining traces are not handled, the shape of the traces will be transferred to the surface of the aspheric lenses. If the processing marks are not treated, the shape of the marks will be transferred to the surface of the aspherical lens, and the scattering phenomenon (diffraction phenomenon) will appear after the lens is made, causing the image to appear halo, resulting in a reduction of the quality of the photo.

Currently, in the manufacture of camera lenses, the processing marks are only slightly smoothed, so that the effect of the lens marks on the photos cannot be seen when viewing the photos on the screen, but when printed as a large photo, it is possible to tell whether the lens used is good or bad.

In order to achieve the finest surface, polishing is required to eliminate process marks.

However, over-polishing can jeopardize dimensional accuracy, and prolonged polishing is not recommended even with NC control, so for carbide and SiC, it is recommended to use a soft, small-diameter tool with diamond abrasive or abrasive paste, and to process with NC control.

In addition, when polishing, it should be noted that if the workpiece is made of Cemented Carbide and is processed with a soft ball-shaped rotary tool and diamond polishing paste, the Cemented Carbide, which is a powder-sintered material, will be degranulated, which will damage the luster of the lens.

The lens of a monocular camera is composed of multiple lenses to correct aberration, if the combination of good precision and surface roughness of the lens, add a few residual traces of processing, less accurate lens, may affect the resolution of the camera applied to the large screen presentation.

Moresuperhard's Grinding Solutions for Glass Molding:

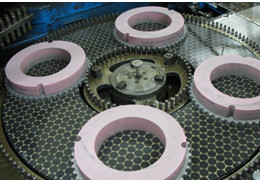

Resin Diamond & CBN Grinding Heads/Pins/ Mounted Points for Internal Grinding

| Internal Grinding Wheel D(mm) * T(mm) * H(mm) * X(mm) |

| D25*T12*H6*X6 |

D25*T24*H6*X6 |

| D30*T12*H6*X6 |

D30*T24*H12*X6 |

| D35*T24*H6*X6 |

D40**T12*H6*X6 |

| D40*T24*H12*X6 |

D50*T24*H12*X5 |

| D50*T24*H12*X10 |

D60*T6*H16*X10 |

| D75*T24*H12*X10 |

D100*T12*H12*X10 |

| D100*T24*H12*X10 |

D125*T25*H12*X10 |

| D150*T25*H12*X10 |

|

| Special size can be design according to customers’ requirement |

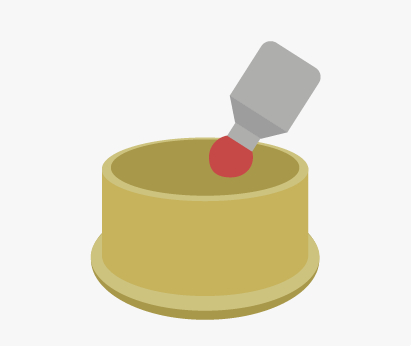

Diamond Polishing Paste Diamond Compound:

.jpg)

The main application of Diamond polishing paste, diamond compound

-Polishing of metal workpieces (such as measuring tools, cutting tools, knives, molds, etc.)

-Grinding and polishing of tungsten steel molds, optical molds, injection molds, etc.

-Grinding and polishing of jewelry, jade, gems and agate crafts

-Optical lenses, crystals, wafers, integrated circuits, quartz wafers, monocrystalline silicon wafers, sapphire, semiconductors

-Grinding and polishing of precision ceramics, magnetic materials, magnetic heads, iron hydrochloride, cemented carbide

-Fine grinding of metallographic and petrographic samples of high-hardness materials, etc.

-Precision medical equipment, dental materials (dentures) grinding and polishing

.jpg)