Classification of diamonds

Diamond is mainly divided into single crystal system and polycrystalline system.

The single crystal system is divided into natural diamond ND and synthetic single crystal. Among them, synthetic single crystal is divided into artificial single crystal MCD and synthetic single crystal CVD.

The polycrystalline system is divided into polycrystalline diamond PCD and chemical vapor CVD.

The difference between different types of diamonds

Natural diamond (ND): It is the hardest substance in the known minerals.

Single crystal diamond: Artificial synthetic single crystal diamond MCD is a diamond recrystallized and grown by graphite powder and alloy catalyst under high temperature and pressure.

Chemical vapor deposition diamond (CVD): refers to a diamond film synthesized on a heterogeneous substrate by chemical vapor deposition, which has exactly the same structure and characteristics as natural diamond.

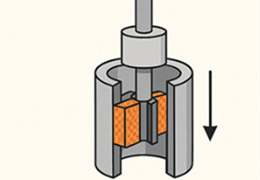

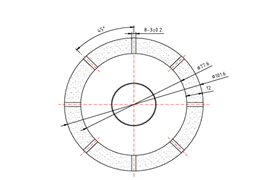

Polycrystalline Diamond (PCD): PCD is a polycrystalline sintered body. The artificial diamond particles that have been rigorously screened are sintered using cutting-edge technology of high temperature and high pressure, and the artificial diamond crystal particles are tightly combined on the tungsten carbide base. In some actual processing cases, it has been proved that its life is more than 50 times longer than that of tungsten steel. Because the diamond powder is randomly oriented, there is no problem of directionality. It can be made into various shapes of blades through precision grinding, suitable for continuous or broken Continuing cutting processing fee for ferrous metal materials.

Diamond application

Natural diamond tools are mainly used for ultra-precision mirror processing of copper and copper alloys, gold, silver, rhodium and other precious non-ferrous metals, as well as special parts, such as VCR disks, optical plane mirrors, polygon mirrors and quadric mirrors. But its crystal anisotropy makes cutting tools expensive.

The performance of PCD depends on the content of diamond grains and cobalt, and the tool life is 10 to 500 times that of cemented carbide (WC matrix) tools. It is mainly used for turning and processing various non-ferrous metals such as aluminum, copper, magnesium and their alloys, hard alloys and non-metallic materials such as fiber plasticized materials with strong wear resistance, metal matrix composite materials, and wood.