Copper has good ductility, which is easy to cause porosity blockage, so that the grinding wheel loses heat dissipation ability.Then cause the workpiece burn or expansion deformation, belongs to one of the difficult grinding materials.

When grinding, the grinding wheel can be selected according to the characteristics of copper.

The main processing properties of copper are as follows:

Grinding properties of copper

1.The grinding wheel is easy to be blocked and the workpiece is heated and deformed

Due to the good ductility of copper, it is easy to cause the blowhole blocking and the grinding wheel loses the heat dissipation ability, thus causing the workpiece to burn or expand and deform.

2.Copper material is easy to adhere, grinding slip, vibration

After grinding, the copper material is easy to adhere to the abrasive grain, so that the abrasive grain loses the grinding force, easy to leave vibration traces on the workpiece.

3.Easy to scratch, improve gloss is not easy

The grinding copper material is easy to stick to the surface of the grinding wheel and cause scratches as the grinding wheel rotates. It is not easy to improve the gloss.

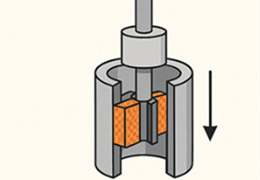

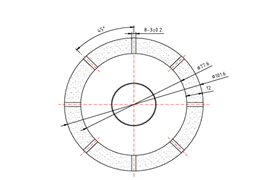

We can improve the pore of its structure, via the treatment of pores can reduce the blockage, grinding heat and improve the adhesion problem.

Through the treatment of pore, can provide the chip hiding space, reduce the scratch problem. And fine grain still has large pores, even fine grain grinding wheel can still make large pores specifications, can simultaneously improve the gloss and avoid blockage, burn deformation!

.jpg)

The grinding wheel with the "pore technology" of both large and small pores can also dissipate heat smoothly with fine grain size, improve the surface roughness and at the same time, do not have to worry about grinding heat problem.

Moresuperhard developed a kind of metal bond diamond wheel to grind brass copper, if you are in need, feel free to contact us.

.jpg)