Before grinding, should check the grinding wheel. If the grinding wheel is beating, the cylindrical surface is irregular, and the fillet corner is too large, it needs to be dressed. Generally can use grinding wheel dresser(diamond dresser, dentate dresser) to dress the cylindrical surface of grinding wheel; also can use used grinding wheel with relatively large hardness for dressing. If the grinding wheel profile is not smooth, you can replace the grinding wheel.

Face grinding technology of end mill cutter:

1.Smooth the end face of end milling cutter

No matter how many flutes of the end milling cutter, first of all to the edge face perpendicular to the axis of grinding flat, this is to ensure that the highest point of the tool can be in the same plane. Correcting the verticality of the edge face relative to the axis of the milling cutter can be done as follows.

(1)visual inspection. With the help of a flat plate, the edge of the end milling cutter is placed face down on the flat plate to observe the left and right tilt Angle. Then rotate the milling cutter 180°and observe its left and right tilt Angle. If the inclination Angle observed twice in the same direction is different, it shall be polished until the inclination Angle observed twice in the same direction is the same. Then rotate the cutter 90°and repeat the action.

(2)Correct with a square. In a flat plate with 90°square correction, the milling cutter and square are put flat to observe whether there is clearance between the milling cutter and square or whether the clearance is uniform, and then according to the clearance to judge the verticality of the milling cutter, milling cutter for grinding.

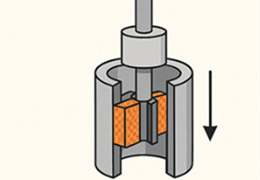

(3)Self- correction.

When you clip an end milling cutter on a drill or a milling machine clamp, put a used grinding wheel under it, and pick up a good rotational speed to turn on the machine, and then move the milling cutter down and grind on the grinding wheel, what you do is to grind based on what's happening on the end face

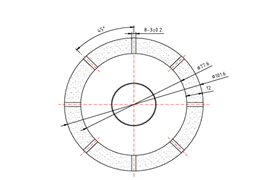

2.groove of end mill cutterGrind cross chip

If there is no circular groove in front of the end face of the four-flute end milling cutter, you need to use the fillet of the grinding wheel to reopen the cross groove along the direction of the spiral groove of the milling cutter, with a depth of about 1 ~ 2mm (too deep to crack, too shallow not easy to grind out the secondary back corner). When grooving, pay attention to the side of the grinding wheel not to touch the other cutting edge below (Note: this cross groove has the function of chip removal, if not opened, the Angle of the cutting edge that goes into the middle concave should be increased).

3.Edge Grinding of end face of end mill cutter

(1)When sharpening each edge separately, the point of each edge is taken as the benchmark and the principle is to keep the point tip of the insert. Grind rake angle (do not need to grind if there is no chipping edge), clearance angle, secondary clearance Angle (if it is a large amount of cutting need better strength, it is recommended to increase the wedge angle of the insert in front of the sharpening tool) and edge angle.

(2)The selection of angle is rake angle 6°~ 8°, (secondary relief angle 30° ~ 45°) edge Angle 1° ~ 3°. The choice of the clearance angle should be changed according to the hardness of the workpiece, and the angle is smaller when the hardness of the material is larger.

The principle of selecting the angle of insert inclination is that all four edges must be concave to the middle, and the flatter the angle, the better the roughness accuracy. In this case, the deeper the machining depth (such as greater than 2mm but within the allowable range), the better the roughness accuracy will be, because the whole cutting edge is involved in the cutting result.

(3)When finish grinding, set up the milling cutter on a platform. If the axis is vertical, all the edge tips can be even, and the angle of the insert can be even, so that it can meet the requirements.

In the manual grinding, the height and angle of the insert are not easy to grasp, should train vary from person to person, as long as the attention to grinding out a little clearance angle can be. The top edge is not usually as long as the highest tip can be, and if it is not the case of the processing of the inner cavity angle, you can also grind the tip of the chamfering greater than 0.2mm to increase the strength of the tip.

4.Grind the main edge (or side edge) of an end mill

If the main edge of the end milling cutter is worn, it is necessary to grind along the spiral line on the grinding wheel (a smaller diameter is better) (it is difficult for beginners to grind). However, there is generally a taper after grinding. The smaller the taper, the higher the level of operation.

Moresuperhard has much experience in making grinding wheels for surface grinding, flute grinding, rake angle grinding, clearance angle grinding, gashing of end mill cutters.

► Fluting Grinding (1A1, 3A1, 14A1, 1V1)

► End Face grinding (11V9, 12V9, 11V2)

► Gashing (1V1, 12V9, 14V1)

► OD clearance grinding (12V9, 11V9, 12V5, 11V5)