What is Electrolytic Grinding?

I. Principle of Electrolytic Grinding

I. Principle of Electrolytic Grinding

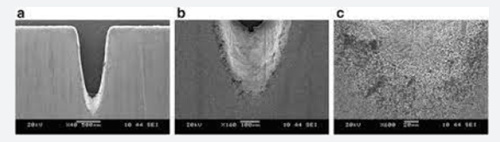

Electrolytic grinding is a processing technology that combines the principles of electrolytic and mechanical grinding. In the process of electrolytic grinding, the electrolytic grinding wheel plays a key role. These grinding wheels are made of electrolytic substrate combined with abrasives, and the common types are metal bond diamond grinding wheels, electroplated diamond grinding wheels, copper-based resin bond grinding wheels, ceramic silver infiltration grinding wheels and carbon bond grinding wheels, etc. The choice of which type depends on the specific application.

2. The scope of application of electrolytic grinding

Electrolytic grinding is especially suitable for dealing with metal materials that are difficult to grind such as high strength, high hardness, heat sensitivity and brittleness, such as cemented carbide, high-speed steel, titanium alloy, stainless steel, nickel-based alloys and magnetic steel. Through electrolytic grinding, it can process all kinds of carbide cutting tools, plug gauges, rolls, wear-resistant bushings, mold planes and stainless steel injection needles.

3. The advantages of electrolytic grinding

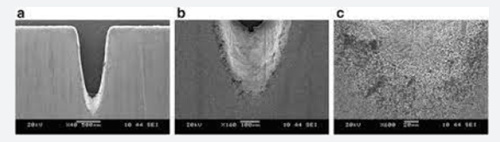

Compared with traditional mechanical grinding, electrolytic grinding has higher efficiency, lower grinding wheel loss, and the processed surface will not produce grinding burns, cracks, residual stress, processing of deterioration layer and burrs and other problems. In addition, the surface roughness of electrolytic grinding is usually low, generally within the range of R0.63 to 0.16 micron, up to R0.04 to 0.02 micron.

4. The processing strategy of electrolytic grinding

In the electrolytic grinding process, in order to improve the machining accuracy, electrolytic grinding wheels that also have the ability of pure mechanical grinding are sometimes used. In the roughing stage, it mainly relies on the high efficiency of electrolytic grinding to complete most of the processing volume. Then, in the finishing stage, will cut off the electrolytic power supply, only rely on pure mechanical grinding to remove the remaining machining allowance, which can significantly improve machining accuracy.

5. Electrolytic grinding wheel type

In the electrolytic grinding of highway cover molds, the commonly used electrolytic grinding wheels have two kinds of copper-based and graphite. Copper-based electrolytic grinding wheel has good electrolytic performance, and the machining gap can be obtained through the anti-copy method. And graphite grinding wheel will produce spark discharge between it and the workpiece during grinding, which has the dual role of electrolytic grinding and EDM grinding. In the fine grinding process after power off, graphite also has the role of lubrication and polishing, which can obtain a better surface roughness.