What are the characteristics of inner circular grinding compared with outer circular grinding?

Compared with outer circular grinding, inner circular grinding mainly has the following characteristics.

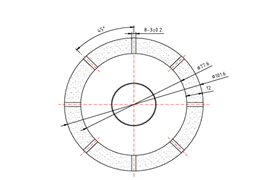

1. Grinding accuracy is difficult to control. Because of the large contact area between the grinding wheel and the workpiece, the heat is large and the cooling condition is poor, the workpiece is easy to produce thermal deformation. Especially because the sand wheel shaft is long and thin, the rigidity is poor, and it is easy to produce bending deformation, resulting in cylindricity error. Therefore, it is generally necessary to reduce the grinding depth and increase the frequency of light grinding.

2. Grinding surface roughness Ra is large. Generally, the wheel speed in inner grinding is less than 2000r /min. Due to the small diameter of the wheel, its linear speed is difficult to reach 30 ~ 50m/s in outer grinding. Roughness Ra value of inner circular grinding is generally 1.6 ~ 0.4μm.

3. Low productivity. Because the diameter of the grinding wheel is small, the wear is fast, the coolant is not easy to wash away the debris, and the grinding wheel is easy to be blocked, so the grinding wheel needs to be dressed or replaced frequently. In addition, in order to ensure the accuracy and surface roughness, it is necessary to reduce the grinding depth and increase the number of light grinding, which will inevitably affect the productivity.