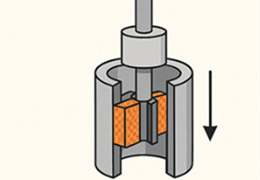

Prior to grinding, a number of stages are involved in gear manufacturing:

Hobbing is a roughing operation which produces a gear profile

with stock remaining for a final grinding process (see figure 1).

Hardening/Heat-Treating

Hardening/Heat-Treating is a group of processes used to

alter the physical, and sometimes chemical, properties of a material.

Treatment involves the use of heating or chilling, normally to extreme

temperatures, to achieve to desired result such as hardening or

softening of a material. Heat-treatment techniques include annealing,

case hardening, precipitation strengthening (age hardening),

tempering and quenching.

Grinding produces a high quality surface finish, correcting any

distortion following heat treating, establishes profile dimensional

accuracy. In some cases, grinding can be utilized to grind gears from

solid eliminating the hobbing process.