The wide width of the centerless grinding wheel is based on the advantage of the long processing distance of centerless grinding. So the dressing of centerless grinding wheels is also very challenging.

Because the purpose of grinding wheel dressing, the first is rounding, that is, the shape, and the second is to repair the sharp teeth, that is, to let the sharp teeth on the grinding wheel in the exposure. However, in the case of centerless grinding wheels that are very wide, the diamond portion of the dresser is likely to be consumed so much that the rear portion will not be able to touch the wheel, not to mention flattening the wheel.

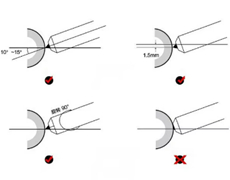

Generally common dressing methods:

.jpg)

1 Use a natural diamond with a large carat weight. Natural diamonds are more expensive, and although they are highly resistant to abrasion, their quality is inconsistent.

2 Multi-point diamond dressing pen. It is to contain many small diamonds on a flat surface so that the grinding wheel can be easily smoothed. And the price of this kind of dressing pen is lower, so, it is often used to dress centerless grinding wheels.

Effect of Centreless Grinding:

1 Natural diamond. Though the wear resistance is high, its abrasion has a specific direction. Although, the volume of dressing process is not easy to reduce, but the sharp angle will still be depleted, so the effect of sharpening is still unstable!

2 Multi-point dressing pen many tiny diamond, although can play the effect of unity strength, solve the problem of resistance to wear, but, many tiny diamond group is not easy to penetrate deep to cause abrasive grains broken, but is not conducive to the effect of repairing sharp.

In summary, for centerless grinding wheel dressing, not only should have like multi-point dressing pen wear resistance, but also to have a single-point dressing pen to repair the sharp effect.

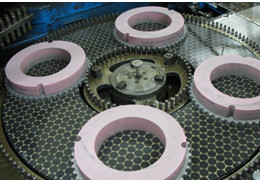

Moresuperhard Centerless Grinidng Machine and Grinding Wheels

High Precision CNC Centerless Grinder

►High Precision Centerless Grinding Machines Models:

-FX12CNC

-FX18CNC-4

.jpg)

►Broad Applications:

-Automotive Industry: shafts, pins, valves, and bearings

-Aerospace Industry: turbine shafts, landing gear components, and fuel system parts

-Medical Industry

-Tool and Die Industry

-Bearings industry

-Tool and Die Industry: cutting tools, punches, and dies with high accuracy and surface quality

Centerless Diamond Grinding Wheel - Resin Bond

.jpg) ► Application

► Application: grinding carbide, ceramic, magnetic materials, stainless steel bar, PCD & PCBN compositives

► Model: 1A1 , 6A1, 9A1

► Bonded Type: Resin bond, Metal bond

.jpg)

.jpg)

.jpg)