New materials often cause a domino effect on aerospace processing technology. Environmental problems have forced a change in materials from traditional chromium electroplating to HVOF spraying coating, which in turn affects the selection of grinding wheels and ultimately the selection of grinding machines themselves.

It swings between two lines

The HVOF coating materials in aviation parts has had a positive impact on the aerospace industry. HVOF coating materials are not only more environmentally friendly but also more resistant to wear and tear and therefore last longer. During the migration, there is also a shift in the grinding process used to produce the parts. While resin-bonded diamond wheels are an old standard, vitrified bonded diamond wheels are now more popular because resin-bonded diamond wheels cannot be dressed in machines. This poses a challenge to maintaining consistency. By using a vitrified bonded diamond grinding wheel, one can use a rotary dresser and a rotary dressing diamond wheel on the spindle to dress the grinding wheel. This breaks the situation that diamond grains can only be bonded in the grinding wheel, creating a completely new cutting surface on the grinding wheel. Bonding operations can be done online and during the manufacturing process.

Technological leap

Technological leap

Recently an aerospace parts manufacturer set out to implement these new technologies and managed to find a new process for producing parts. In this case, the component is the fuse pin that holds the aircraft engine to the wing. Fuse pins are HVOF Tungsten Carbide Co-Cr, 2-1/2" diameter x 8" long, with a diameter deviation of 0.01", and require surface finish of 8RA.The manufacturer had already chromed parts for its customers. After updating the material requirements, the manufacturer needed to develop a new HVOF spraying process. Initially the manufacturer knew that this required a tool grinder, which has good rigidity - The experienced Okuma had known and had been using for years to grind chrome in the equipment. So, along the way, the Okuma official company was called in to collaborate and to inject expertise into the team with HVOF grinding technology that was not available within the manufacturer.

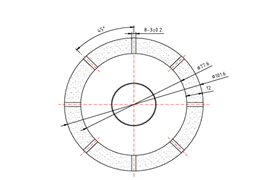

Resin-bonded diamond wheels would have met the customer's specifications, but after the Okuma team showed the benefits of using vitrified diamond wheels, the customer allowed them to be used as an alternative. That company knows that Vitrified diamond wheels offer more productivity because they could dress the wheel on the machine and do not take it off the machine, which eliminates the need for off-line operations. The vitrified diamond wheel from one of super hard material company was selected for a 220 mesh, 24" diameter ×1-1/4" wide and set to operate at 6000sfm. Okuma's GP-36FII X 1500 grinder is preferred.

Key Characteristics

Now that HVOF materials and Vitrified diamond grinding wheels have become the new standard, the capability of CNC grinding machines is more important than ever. Okuma's grinder has several important features and capabilities that should be taken into account when optimizing the process and maximizing productivity. Okuma's GP-36FII X 1500 grinder was selected based on its functions in the following aspects.

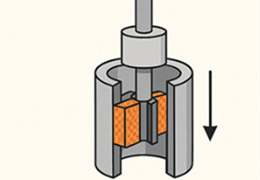

Rotary Dressing

Rotary Dressing

With a Vitrified diamond wheel, a more open and free-cutting wheel is created when the diamond rotary dresser and wheel operate in a one-way rotation (relative rotation), allowing for more active grinding. The rotary dresser can also rotate in reverse, providing a higher surface finish. It is worth noting that the grinding wheel is not very sharp in this case, which is why it leads to better surface finish. The ability to rotate dressing provides a variety of ways to adjust the grinding wheel. However, resin bonded grinding wheels also require alumina dressing sticks. This involves the operator picking up the dressing rod and pushing it into the grinding wheel to expose the cutting area, thus introducing uncontrollable variables into the process flow. Depending on the operator, the dressing stick should be able to be applied under different pressures and create different conditions for the grinding wheel according to the working time. By combining the vitrified diamond grinding wheel with the rotary dresser, a consistent quantity can be dressed at a constant and steady feed speed, so that stable results can be obtained.

Acoustic Sensor

The sensor detects when the wheel touches the rotary dresser, so the exact area and time of contact is known. This prevents excessive trimming from cutting off the grinding wheel. Take the fuse pin as the example, a grinding wheel of this size can cost $6,000 to $7,000, so it is ideal to trim as little as possible to extend the life of the wheel. The cost basis is obvious. By minimizing the amount of grinding wheel dressing, one can reduce the reduction to 0.0001" instead of 0.0005". This saves material.

High precision static and dynamic rigidity

Okuma grinder provides static and dynamic rigidity to the machine with two key functions. The first is the guide system, which is an open V-shaped and flat guide with extremely high stiffness and no slippage. The second is the spindle of the hydrodynamic grinding wheel, which has very good rigidity. The supporting force at the center is 1 ton, the offset radial load is equivalent to about 1 per 100kg, and the rotation accuracy is 0.0000004". This provides a higher surface finish for the diamond wheel, while rigidity prevents vibration in the system, which is necessary for grinding very hard materials such as Stellite.

During the transition period driven by the demand for new materials for aerospace components, we have the opportunity to update the entire process flow. Through adding the unique design capabilities of vitrified diamond grinding wheels and suitable grinding machines to the process flow, it is possible to achieve greater overall productivity.