The accuracy of the work piece depends largely on the consistency of the process system state.After dressing the layer thickness decreases and the grinding wheel local changes to the designated calibration position, which leads to the change of the state of the whole process system, so the size consistency cannot be guaranteed.Therefore, it is very important to compensate the grinding wheel after dressing.

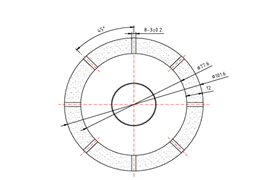

The dressing process of grinding wheel is a comprehensive result of the mutual grinding of two abrasives. Not only will the abrasive thickness of grinding wheel decrease, but also the abrasive thickness of dressing wheel will decrease.

The hardness and wear resistance of diamond grinding wheel are much higher than GC cup dressing wheel.It can be predicted the abrasive thickness reduced amount of diamond grinding wheel is far less than that dressing amount.

The relationship is:

Dressing amount = reduce amount of grinding wheel + reduction of dressing amount

The reduction of the grinding wheel after dressing should be compensated In order to ensure the size consistency of the work piece. For example, when the dressing amount is 0.03mm, the thinning of grinding wheel is 0.0015mm, and the thinning of dressing wheel shoule be 0.0275mm.