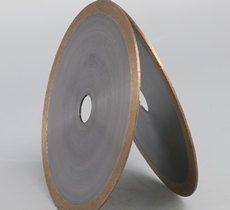

A metallographic cutting blade, also known as a metallographic cutting wheel, is mainly used in the process of sample cutting in the metallographic sample-making process. The metallographic cut-off sheet is born from the wet grinding wheel cut-off sheet in the ordinary grinding wheel cutting, and after improving the cutting accuracy and cutting temperature control, it forms the metallographic cut-off sheet which is suitable for the demand of metallographic sample making, and it is also mainly three types of alumina resin cut-off sheet, silicon carbide resin cut-off sheet and diamond sintered cut-off sheet.

What are the differences between metallographic cutting blade and ordinary cutting blade?

What are the differences between metallographic cutting blade and ordinary cutting blade?

1, cutting blade thickness: metallographic cutting sheet than general wet grinding wheel sheet to thin, for example, 300mm diameter alumina general film thickness is 3.2-3.8mm thick, the gold photo is 1.5-2mm thick, thinner is to better control the cutting into the knife cutting stress caused by the plastic deformation of material tissue, but also can better control the accuracy of the cutting position.

2, cutting blade elasticity: the elasticity of the gold photo is better than the general-purpose sheet, better elasticity can better buffer the sample tissue plastic deformation brought by the knife load, more flexible to adapt to the metallographic cutting is constantly changing cutting speed to adapt to the changes in cutting torque output.

3, high efficiency and precision film: gold photo is also subdivided into high-efficiency film and precision cutting film according to the different cutting precision, the precision cutting film has higher resin content and better elasticity, and the thickness of the cutting film is thinner.

What are the cutting principle and service life of metallographic cutting blades?

.jpg)

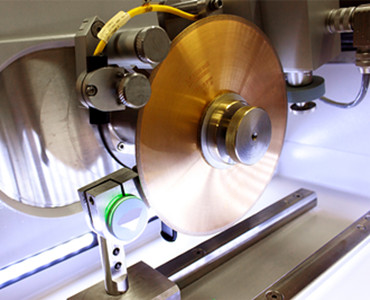

Metallographic cutting blade maximum cutting capacity = cutting wheel radius - cutting protection flange radius, if you need to cut harder materials, in order to protect the cutting blade need to replace the larger diameter of the protection flange, but the cutting diameter to reduce some.

Metallographic cutting blade life, due to the resin content being higher than the ordinary sheet, so the service life will be short, if not to protect the motor is not overloaded and bursts the blade, life reduced performance is mainly cutting wheel diameter with the use of smaller.

Cutting blade rated maximum speed: the speed of metallographic cutting is basically from 50rpm to 4000rpm free variation, but the cutting blade is generally marked with the rated maximum speed, which you need to determine before use.

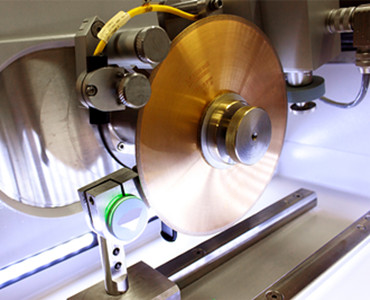

Applications of metallographic cutting blades:

Cutting Blades can cut the following materials:

Plastics, rubber - non-ferrous metals, cast iron, stainless steel, tool steel - hardened steel, spring steel, bearing steel - alloy steel, heat treated steel - sintered materials, ceramics, silicon wafers, quartz, and cement.

.jpg)

.jpg)