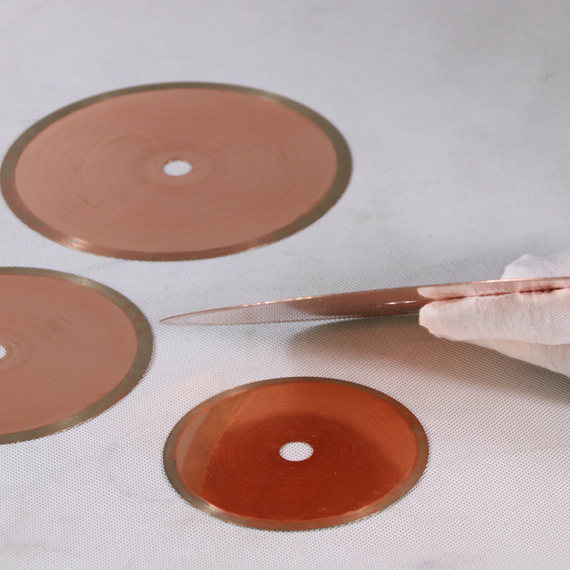

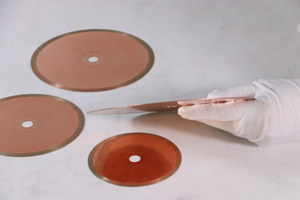

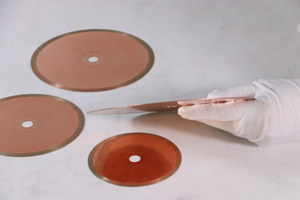

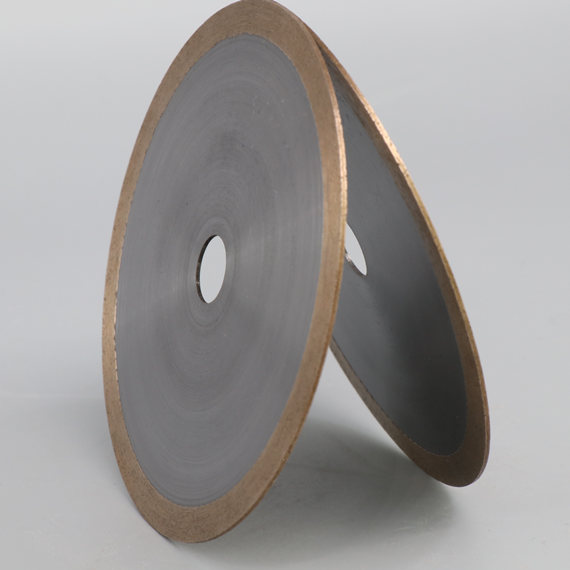

The premise of metallographic analysis is to prepare better metallographic sample products. At present, metallographic samples are mainly prepared by diamond and cbn cutting discs. Therefore, it is particularly important to choose high-quality metallographic cutting wheels. Diamond blade is a saw blade which has diamonds fixed on its edge for cutting hard or abrasive materials. Cutting precision 0.01mm.

Applications of Diamond Cutting Blade Saw

precision cutting hard materials, ceramic and petrographic samples, plastics and polymers, steel, non-metallic material, circuit board, semiconductor, composites,glass,quartz, crystal, metallography, photonics, semiconductor, etc

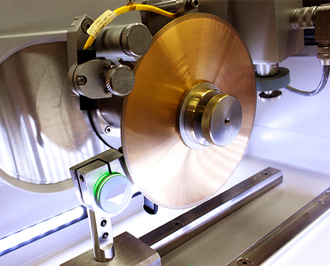

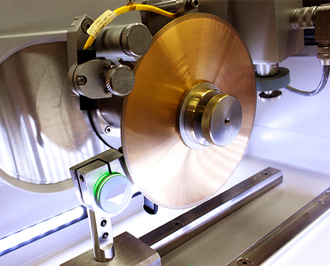

Cutting machine: cutting OM (optical microscope), SEM (scanning electron microscope), and even TEM (transmission electron microscope) specimen.

The main features of metallographic diamond cutting saw blades

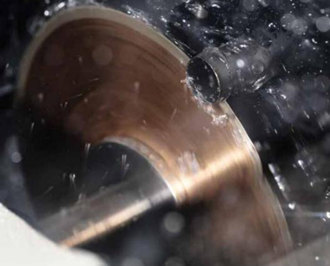

1. Cutting disc thickness: Metallographic cutting discs are thinner than general wet grinding wheel discs, but not easy to crack. For example, the thickness of 300mm diameter alumina general disc is 3.2-3.8mm thick, and the thickness of gold photo is 1.5-2mm. The thinner is for better control of cutting. The plastic deformation of the material structure caused by the cutting stress during the cutting process can also better control the accuracy of the cutting position

2. The slit is narrow, which can greatly increase the utilization rate of valuable raw materials

3. High efficiency, sharp cutting, no need for frequent tool changes

4. High rigidity, high strength, long service life

5. Better elasticity: better buffer the plastic deformation of sample tissue brought by feed load, more flexible to adapt to metallographic cutting is constantly changing the cutting speed to adapt to the change of cutting torque output.

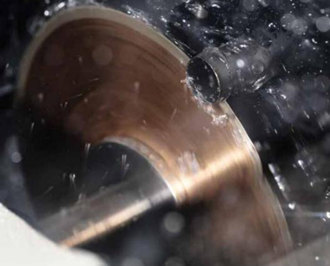

8. Minimal cutting heat

.jpg)