Recently, one of our customers in Singapore wanted to order some electroplated diamond belts to polish tungsten carbide. We recommend resin diamond belt to this customer, because the polishing surface of resin diamond belt will be more shiny than that of electroplated diamond belt.

So today, specifically introduce the difference between electroplating and resin bond of diamond belts!

What is the difference between electroplated diamond abrasive belt and resin diamond abrasive belt?

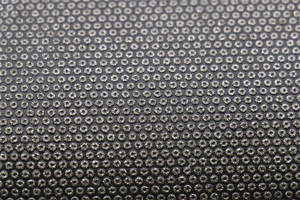

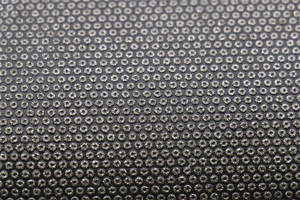

1. In terms of bond, resin diamond abrasive belt mainly uses phenolic resin and a small amount of metal powder as the bond, while electroplated diamond abrasive belt is a kind of abrasive belt production process that deposits nickel drill alloy on the surface of metal matrix and fixes diamond abrasive by electrodeposition.

2. In terms of processing efficiency, because the electroplated diamond abrasive belt uses higher-grade abrasive and has only one layer of abrasive, it has its own advantages in heat dissipation performance, so the processing efficiency of the electroplated diamond abrasive belt is higher.

.jpg)

3. In terms of service life, the electroplated abrasive belt has only one layer of abrasive, so the service life of the electroplated abrasive belt is inferior to that of the resin diamond abrasive belt.

What are the advantages and disadvantages of electroplated diamond abrasive belt?

Advantages of electroplated diamond belt:

1. Electroplating process is simple, investment is small, and production is convenient

2. Easy to use.

3. The single-layer structure determines that it can reach a high operating speed

4. Although there is only a single layer of diamond, it still has enough life.

Disadvantages of electroplated diamond belt:

1. There is no strong chemical metallurgical bonding between the coated metal and the substrate and the abrasive interface. The abrasive is actually only mechanically embedded in the coated metal, so the operating force is small, and the diamond particles are heavily loaded. Efficient grinding is easy to fall off (or the coating falls off in pieces), resulting in overall failure.

2. In order to add control force, it is necessary to add coating thickness. As a result, the exposed height of abrasive particles reduces the chip space, the abrasive belt is easy to block, the heat dissipation effect is poor, and the workpiece surface is easy to burn.

.jpg)