Engineering ceramics have light weight, corrosion resistance, high temperature resistance, low thermal expansion coefficient, thermal shock resistance and self-lubrication ability, wear resistance and low friction coefficient of excellence. It has been widely used in energy engineering, automotive industry, machinery, chemical oil, aerospace, metallurgical building materials and military engineering and other fields.

However, engineering ceramics also have some defects, mainly for brittleness (easy to produce cracks), poor uniformity, low toughness, low strength, poor reliability, poor machinability.

Diamond abrasive for grinding zirconia ceramics

Zirconia ceramics are hard and brittle and difficult to work

Diamond abrasive for grinding zirconia ceramics

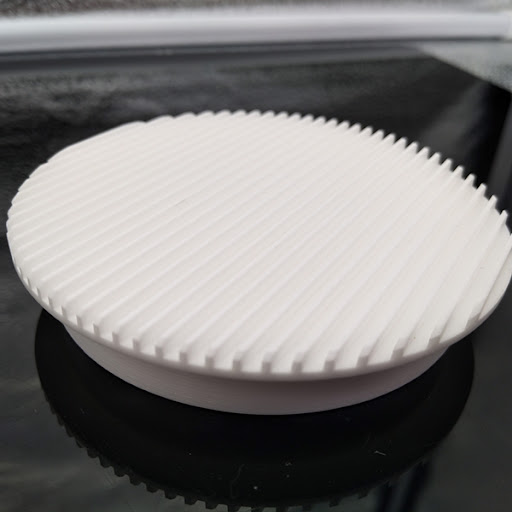

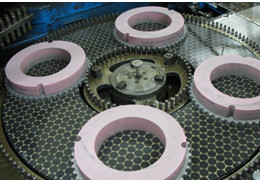

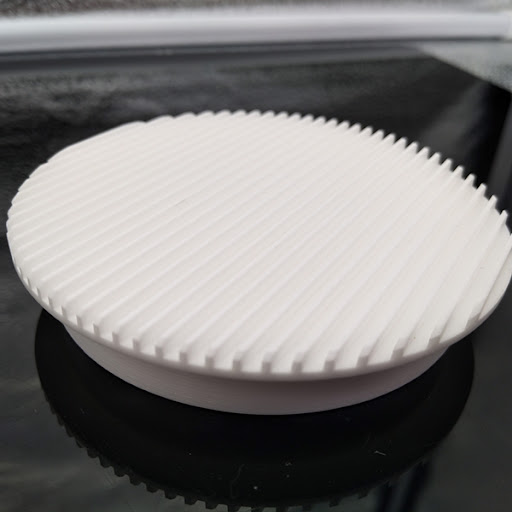

Zirconia ceramics are hard and brittle and difficult to work. Diamond abrasives are often used in grinding. According to different bond, diamond grinding wheel can be divided into resin bond diamond sand, ceramic bond diamond grinding wheel and metal bond diamond grinding wheel.

1. Resin bond diamond grinding wheel is mainly made of thermosetting resin, which has the advantages of low curing temperature and relatively simple preparation. They are mainly used for hole grinding, cylindrical grinding and surface grinding.

2. Metal bond diamond grinding wheel bond agent and abrasive strong, good toughness, can withstand a large load, used in hard and brittle material complex surface grinding, precision and ultra-precision grinding.

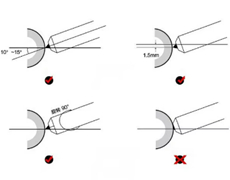

Due to the characteristics of ceramic materials (such as high hardness, brittleness, thermal vibration sensitivity, etc.), specially care needs to be taken during machining. Unlike hard metals, ceramic materials are less likely to have sharp points created by grinding through plastic deformation due to their high brittleness. Therefore, processing takes account of this missing plastic property. In grinding ceramic materials, diamond grinding discs bonded by synthetic resin have outstanding performance due to their high hardness. Using synthetic resin adhesive, can realize relatively small processing force, reduce the wear degree of grinding disc, make the workpiece achieve better surface quality and shape precision. However, due to poor thermal conductivity of synthetic resin bonded grinding discs, high temperatures may occur in the grinding process.

Ceramic bond is different. Due to its good porosity, lower temperatures can be achieved during grinding. It also usually has a high effective hardness.

---EDITOR: Doris Hu

---POST: Doris Hu