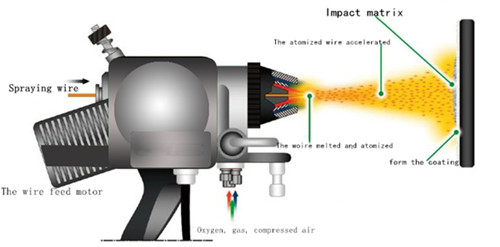

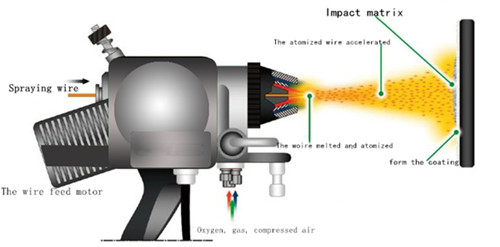

Thermal spraying technologyis a method of using heat source to heat the spraying material to melting or semi-melting state and spray deposition to the surface of the pretreated substrate at a certain speed to form coating. Thermal spraying technology creates a special working surface on the surface of ordinary materials, so that it can achieve a variety of functions, such as anticorrosion, wear resistance, friction reduction, high temperature resistance, oxidation resistance, heat insulation, insulation, electric conductivity, microwave radiation and so on, so that it can achieve the purpose of material saving and energy saving.

The advantages of thermal spraying technology :

1.The equipment is light, can be site construction.

2. Flexible process, less operating procedures. Fast repair, reduce processing time.

3. Strong adaptability, generally not limited by the size of the workpiece and the site.

4. Coating thickness can be controlled.

5. In addition to spray welding, the substrate heating temperature is low, the workpiece deformation is small, crystal phase structure and performance changes are small.

6. Suitable for all kinds of matrix material parts, almost all solid materials on the surface of the preparation of various protective coating and functional coating.

In the thermal spraying process, the coating material is sent into a high-energy heat source (combustible gas - oxygen - fire source and arc or plasma of inert gases such as argon, hydrogen, nitrogen and helium) and melts. Molten particles accelerate toward the workpiece and collide at high speeds (40 -- 600 m/s). When heat is transferred to the substrate, the particles solidify and layer into a coating. Repeat the process again and again with a burner to achieve the desired thickness. The coating thickness can vary from a few ten μm to a few mm.

During the coating process, the workpiece is usually heated to 150°C and its surface temperature is monitored.

See the spraying technology and application:

|

spraying technology

|

Gas thermometer(℃)

|

Velocity particle(m/s)

|

Adhesion strength(M/Pa)

|

Porosity(Vol/-%)

|

|

Arc spraying

|

4000

|

100

|

10-15

|

10

|

|

HVOF

|

3100

|

40

|

10

|

10-15

|

|

HVFS

|

3100

|

800

|

>70

|

1-2

|

|

PSP

|

15000

|

200

|

>50

|

2-5

|

|

Coating materials

|

Material

|

Melting point(℃)

|

HV 0.3

|

Typical characteristics

|

Application field

|

|

Pure metal

|

Al

|

660

|

80

|

Soft,corrosion prevention

|

Corrosion protection in industrial and Marine environments

|

|

Cu

|

1080

|

120

|

Good thermal and electrical conductivity

|

General sliding surface. Crankshafts, synchronous rings and piston rings, pump parts, guides, diesel engine assemblies, mounting mounts and pressure mounts, to prevent friction corrosion

|

|

Mo

|

2600

|

700

|

Good sliding and emergency running performance, hard, tough, wear resistance, also suitable for anticorrosion. Can form extremely dense protective layer, good compressive strength

|

A conductive layer, as on a non-conductor

|

|

Zn

|

420

|

30

|

Low melting point, good corrosion resistance

|

Corrosion resistant like aluminum (also commonly used as Al/Zn alloys), especially for bridge and crane structures and containers, etc.

|

|

W

|

3400

|

300

|

High melting point element

|

Electrical contact, electrode

|

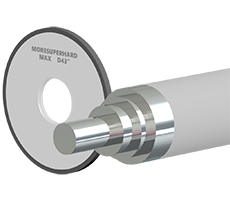

MoreSuperHard provides a full range of thermal spray coating solution and service which includes OD grinding, inside grinding, cylindrical grinding, surface grinding and polishing, etc. We have been present on the Thermal Spraying Coating industry for over 10 years . Our resin diamond wheels for HVOF carbide coating has enjoyed wide popularity in Canada, Turkey, Dubai, etc. Our products cover cylindrical resin diamond wheels , diamond internal grinding wheels and flexible diamond sand belts.

---EDITOR: Doris Hu

---POST: Doris Hu