After grinding, the workpiece surface roughness Ra<0.01m, the light like mirror, can be clearly imaging, so it is called mirror grinding. The flatness of the grinding surface is not greater than 3m/1000mm. Surface grinding of high precision and high added value parts is required.

Surface grinding machine for mirror grinding, often produce some defects, such as surface ripples, burns, scratches, patterns and wear marks (silk flow) obvious, to solve these problems, can take the following measures:

(1) Surface ripples are mostly caused by grinding wheel vibration, such as excessive bearing clearance, spindle deviation, poor dynamic balance of motor rotor, uneven oil film between spindle and bearing, etc. In addition, the wheel is not well balanced will also produce ripples. If the grinding wheel is well balanced, there are still ripples, it is necessary to overhaul or adjust the grinding wheel and its matching parts to completely eliminate the ripple phenomenon.

(2) When machining materials with high hardness, the grinding efficiency of grinding wheel is poor, and the grinding point will produce high temperature, which will easily burn the workpiece (for example, when grinding W18Cr4V, it is more likely to burn). To prevent burns, there must be sufficient grinding fluid at the grinding point. In addition, the amount of back knife should be appropriate, not too large. * The method is to reduce the linear speed of grinding wheel, about 18m/s is appropriate. Using 1440r/min low speed, basically can eliminate the burn phenomenon. Another advantage of reducing the grinding wheel linear velocity is to reduce the vibration of the grinding wheel frame, and also reduce and eliminate the ripple phenomenon.

(3) There are roughly two kinds of scratches in mirror grinding:

* One kind of scratches is irregular, which is caused by impure grinding fluid, impurities and abrasive particles brought out by being rushed to the grinding wheel and the workpiece. The method of eliminating such scratches requires grinding fluid filtration, generally using magnetic, copper wire mesh three filtration.

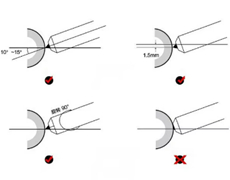

* Another scratch is a line like dotted lines, shallow, the length of the distance is roughly the same, this is the grinding wheel abrasive grain is about to fall off, with the grinding wheel rotation and scratch. At this time, the elimination method is to use sufficient grinding fluid when dressing the grinding wheel, and trim the two end faces of the grinding wheel into oblique shape with wide outside and narrow inside. In addition, the selection of grinding wheel should be appropriate, not too soft, do not use too good grinding wheel.

(4) Mirror grinding, easy to appear pattern shape in a variety of forms. There are many factors that produce patterns in the coating production line, and the main reason is vibration, including periodic vibration of grinding wheel, external influence and vibration of adjacent machine tools, etc., and when the grinding wheel is too blunt and the stroke is unstable, there will be patterns. When the adjacent machine is not in operation when grinding, then the pattern is not easy to appear.

(5) When the grinding crack in mirror grinding is obvious, it is necessary to use fine grit grinding wheel to remove this kind of silk flow. However, when using fine grit grinding wheel, the following points must be considered:

① When polishing grinding wheel, the diamond tool should be sharp, the grinding fluid should be sufficient, and the debris should be washed away in time to avoid affecting the surface of grinding wheel.

② The amount of grinding should be appropriate to prevent surface burns and other defects and affect the surface smooth. Keep proper allowance for grinding.

③ The grinding wheel linear speed must be reduced to 15 ~ 18m/s.

④ The grinding fluid is strictly filtered to prevent scratches.

⑤ When polishing grinding wheel with grindstone, the contact area between grindstone and grinding wheel should not be too small, and the grindstone used should not be too soft, otherwise it will not play the role of polishing grinding wheel.

Grinding parameters:

(1) The back cutting depth of the grinding wheel is about 0.005mm. According to the properties and hardness of the workpiece steel appropriate increase and decrease, such as high hardness of hardened steel, Back cutting depth is too large to cause burns, and soft steel back knife amount is too small and not easy to polish.

(2) Single stroke of horizontal feed is 0.2~0.4mm. The lateral feed speed has a great influence on the surface roughness, because the grinding wheel's cutting ability is very poor in mirror grinding. If the lateral feed speed increases, the grinding wheel surface will be damaged, so it cannot obtain a very smooth surface.

---EDITOR: Doris Hu

---POST: Doris Hu