At present, the pillar industry of powder metallurgy is automobile industry. As powder metallurgy technology is a kind of material saving, energy saving, less investment, no pollution of metal forming process, has long received the attention of the automotive industry, Ford, GM, Toyota, Honda and so on have opened the powder metallurgy business divisions.

Lots of automobile parts are made of powder metallurgy materials, and the

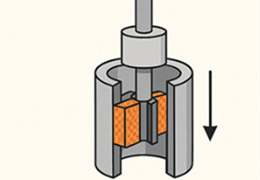

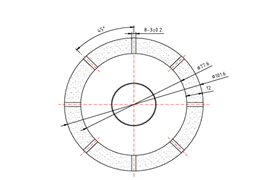

double-disc grinding process of oil pump and rotor, hydraulic motor and rotor, VVT rotor, stator and sprocket workpiece is undergoing subtle changes. Early a few years of powder metallurgy auto parts using the traditional plane grinding machine (or round table grinding machine), grinding disc fine grinding way processing.

From the analysis of grinding time: rough grinding using a round table grinding machine, although the order cost is low, but during the grinding process of dust, serious environmental pollution.

Fine grinding adopts double end grinding machine processing, although in the process of processing 6 built-in planetary wheels, a planetary wheel can be placed in multiple workpiece, seemingly high processing efficiency, but because of more rough grinding process, comprehensive grinding beat will be longer.

From the analysis of grinding accuracy: the size tolerance of grinding deviates greatly. In the actual grinding process, the whole plate is prone to waste.

With the strict control of the processing cost of automobile powder metallurgy finishing enterprises, the requirements for automatic production are becoming higher and higher, and the requirements for accuracy are becoming more and more stable. More and more powder metallurgy finishing enterprises are more willing to use powerful grinding double end grinding machine to do double end grinding of powder metallurgy workpiece.

From the analysis of grinding time : the use of this grinding method eliminates the rough grinding process, looks like a grinding, but because it is a double position continuous grinding, so there is no loading and unloading time, this grinding method can realize automatic loading and unloading, truly mechanized production, the overall processing beat is better than the traditional grinding method. If automatic loading and unloading mode is added, automatic grinding and automatic compensation can reduce the grinding cost due to high compensation accuracy.

It is found that the double-end grinding machine performs well in both the machining thickness tolerance size and the parallelism and flatness of the behavior tolerance, and the accuracy is within 0.003 micron. The double-end grinding machine has more advantages in the double-end grinding of the powder metallurgy workpiece.

In addition , if you have any problems in double face grinding of powder metallurgy in auto parts, you can feel free to contact us, we will help you more!

---EDITOR: Julia Zhang/Doris Hu

---POST: Doris Hu