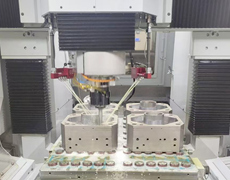

In the mass production of iron castings, removing large residual stock from casting risers is a critical process that directly impacts product appearance and subsequent machining efficiency. When a leading manufacturer of iron castings faced challenges with this task—needing a high-adaptability grinding wheel to tackle thick residual material—we collaborated closely with suppliers to deliver a targeted solution, addressing unexpected issues related to equipment rigidity and grinding performance.

Customer Background & Requirements of Electroplated CBN Grinding Wheel:

The customer specializes in the mass production of iron castings. After casting molding, thick excess material remains at the riser positions, which not only affects the regularity of the workpiece appearance but also hinders the smooth progress of subsequent processing steps. To ensure production efficiency and product quality, the customer urgently needed a highly adaptable grinding wheel that could efficiently remove large stock while maintaining processing stability.

Challenges Encountered

The customer gave high praise to the initial sample, noting that it met all requirements except for slightly lower cutting efficiency. To enhance grinding efficiency, the team switched to a coarser grit (30#) grinding wheel. However, this adjustment led to a new problem: obvious vibration marks on the ground surface. The customer proactively provided feedback and recorded videos for analysis, helping identify the root cause.

Problem Analysis

Our technical team conducted in-depth research and concluded that the core contradiction lay in the mismatch between the coarser grit wheel and the customer’s equipment:

- Coarser grit (30#) electroplated CBN grinding wheels require higher rotational speed and grinding force to achieve optimal efficiency.

- The customer’s equipment was equipped with a relatively slender robotic arm, which could not provide sufficient support for the increased grinding force.

- This mismatch resulted in vibration marks on the grinding surface and even a decrease in actual grinding efficiency—opposite to the intended goal.

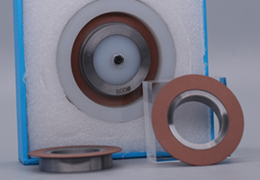

Product Specifications (Customized Electroplated CBN Grinding Wheel)

To address the customer’s large stock removal needs, the customized grinding wheel featured key technical parameters:

- Abrasive Material: CBN (Cubic Boron Nitride)

- Grit Size: 30# (coarse grit for enhanced stock removal efficiency)

- Plating Layer: Heavy-duty electroplated nickel

- Abrasive Protrusion Height: 50% of the particle size

- Abrasive Concentration: High concentration (≈C100)

- Dynamic Balance: G2.5 (at 6000 RPM)

Solution & Collaboration

After analyzing the problem, two feasible solutions were proposed:

- Replace the coarser grit wheel with a finer one to reduce required grinding force (rejected by the customer, as finer grit could not meet the demand for high efficiency).

- Enhance the rigidity of the customer’s equipment robotic arm to support the grinding force of the 30# grit wheel.

The customer opted for the second solution, as it aligned with their long-term production efficiency goals. Our team provided technical guidance throughout the process, ensuring the solution was tailored to their equipment and production needs.

Outcome & Customer Recognition

While the customer is in the process of adjusting the robotic arm rigidity, the initial collaboration has already gained their trust:

- The customized electroplated CBN grinding wheel’s performance (excluding the efficiency-related grit adjustment) was fully recognized, with the initial sample meeting all quality standards.

- Our proactive problem analysis, rapid response, and targeted solutions demonstrated professional technical capabilities, strengthening the partnership.

Once the equipment adjustment is completed, the 30# grit electroplated CBN grinding wheel will fully exert its high-efficiency stock removal advantages, helping the customer achieve stable, efficient casting riser processing.