Vitrified Bonded CBN Wheels for Peel Grinding of Gear Shaft

1. App parameters:

Workpiece: Gear shaft

Material : 16MnCrS5, HRC 58-62

Grinder: JUNKER QuickPoint 5000

Grinding part : Gear shaft journal

Grinding method: spot grinding/

peeling grinding

Coolant : emulsion

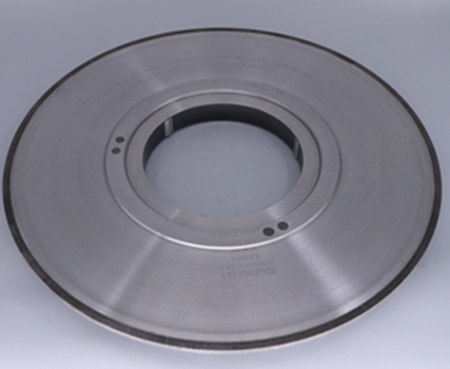

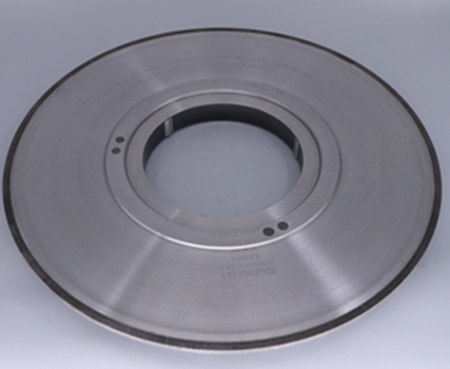

Grinding wheel : MSH D400*5*35 B126

Diamond Roller: Reverse Plated Roller

2. Grinding parameters:

Grinding wheel speed: vc=100 m/s

Grinding allowance: Ø 0.45~0.5mm

Grinding time : 120 s

Workpiece Surface require: Rz 2um.

3. Dressing parameters:

Roller dresser speed : 90 m / s

Dressing amount :3*3 µm

Dressing speed ratio : + 0.90

Moresuperhard Vitrified Bonded CBN Wheels for Peel Grinding of Gear Shaft:

Moresuperhard provides new solutions for rough grinding using a peel grinding technique evolved from previous work. Due to the unique wheel composition, a new high-strength metal bond and innovative diamond qualities the

vitrified bonded CBN grinding wheels offer convincing performance. The process is carried out with an extremely low grinding noise level, wear is significantly reduced, whilst having improved surface quality and an especially high stock removal.

Features of Peel Grinding

— High-precision, high-efficiency

— Center-going, step-difference forming external cylindrical grinding

— The punches and needles are rough and finely ground at one time, and the finish is high

— With less frequent dressing in the case of vitrified CBN wheels or without dressing in the case of plated CBN wheels

.png)

.png)