Recently, Moresuperhard has received feedbacks from customers on the use of our

Resin Bond CBN Wheels for Grinding D2 Cutting Tools. We are very grateful for his feedback!

Looking forward to more feedback from our customers!

Here, we will share the details with you!

Firstly, let us see the details of processing:

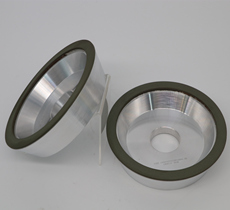

Wheel Bond : Resin bond

Wheel Size: 6A2-D200-T35-X6-W10 B181

Wheel Speed: 30m/s

Workpiece material: D2 tool steel hardened

Workpiece Hardness: HRC 62.

Workpiece Size: W20-L40-T0,86-angle 15°

Workpiece Surface Requirement: Ra 0.8

Grinding Infeed: 0.02mm per pass

Wheel Life: 6000pcs tool per wheel

Moresuperhard Resin Bonded CBN Grinding Wheels for Cutting Machines:

Moresuperhard Resin Bonded CBN Grinding Wheels for Cutting Machines:

►Excellent Grinding Action

►less apt to experience loading, and they dress easily for added convenience

►Convenience and Ease of Use

►Grinding abilities apply to both wet and dry tasks on processing objects such as harden steel, glass, ceramic, carbide alloys, ferrite, refractories, semi conductors, and other electrical carbon products.

The Applications of Resin CBN Grinding Wheels:

Resin CBN grinding wheels are suitable for grinding workpieces such as hardened steel, high-speed steel, cast iron, stainless steel and nitrided stainless steel.

At the same time, in order to improve production efficiency, people began to use CBN grinding wheels on low-speed grinding machines to increasingly replace ordinary grinding tools.

At present, resin CBN grinding wheels are widely used for precision grinding of workpieces containing iron group elements in industries or fields such as automotive, bearings, compressors and precision molds, and have become an irreplaceable tool in manufacturing production and grinding processing.