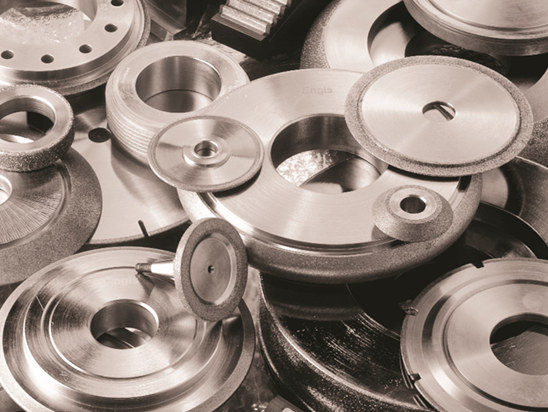

Electroplated bond diamond grinding wheels manufacturer

Electroplated bond diamond grinding wheels

• Electrolytic depositing through a layer of grain on a metallic body

• Very high grip for the highest possible grinding performance

• For pre-grinding complex profiles with high material removal volumes

• For finishing grinding with high precision, for example in the gear-cutting industry

Application and Processing Material for Electroplated bond Diamond Wheels

- Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs

- Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer

- Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel.

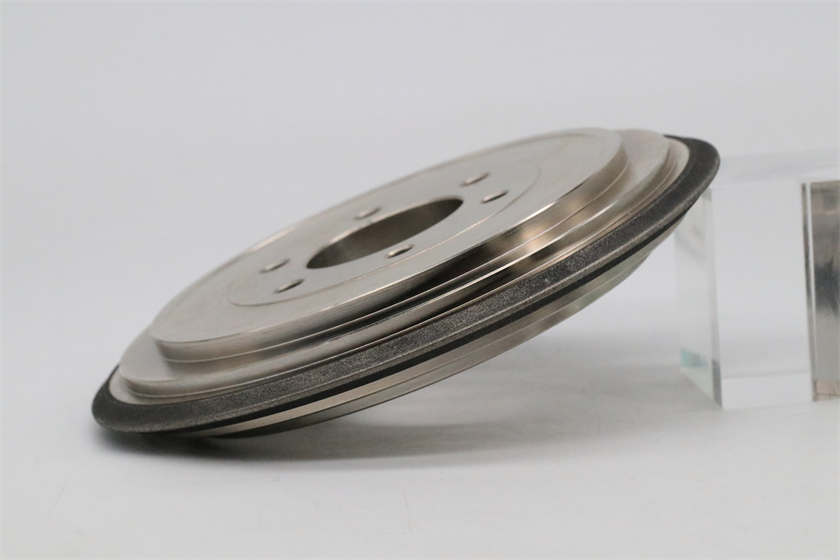

- Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or rimming aluminum oxide wheel

Electroplated Diamond Grinding Wheels

Better removal rates and less heat/thermal damage to the part when an aggressive amount of stock removal is required.

Excellent Form Holding Characteristics

Holds tolerance and simple and intricate shape and forms for the entire life of the tool or wheel, from first grind to last.

Maximum Abrasive Particle Exposure

Gives the most aggressive, open structure of all bonding methods

With faster stock removal and increased speed and feeds, lower your long-term cost with the potential reduction or elimination of time associated with setup, dressing, and tool changes.

Materials processed of electroplated diamond and cbn wheels

- Tungsten Carbide

- Stainless & HS Steel

- Ductile and Cast Irons

- High Temperature Alloys

- Fiberglass

- Inconel

- Composites

- Ceramics

- Glass