How to improve the mirror polishing efficiency of tungsten carbide?

Tungsten carbide has a series of excellent properties such as high hardness, wear resistance, strength, toughness, heat resistance and corrosion resistance, so it is one of the most commonly used workpieces. However, these advantages have also become grinding On a big problem.

Common Problem

1. When rough grinding: If you want to increase the cutting force, the grinding texture is too deep, and fine grinding is not easy to remove the rough grinding texture.

2. For fine grinding: the cutting force is not good, it needs frequent dressing, and it is easy to cause scratches. It needs to be ground in many stages. The dressing is frequent, and it is impossible to expect scratches, which will cause heavy industry to repair and cause low efficiency.

Solutions

1.

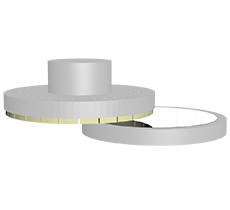

Improve the grinding force of the grinding wheel

It is often misunderstood that reducing the grinding ability to achieve good results during mirror polishing, but the opposite is true. The coarse-grained grinding force is good, and no excessive feeding is required to reduce uneven grinding lines. The fine-grained grinding force is good, and it is capable of removing it. Coarse graining can reduce the number of grinding steps.

2.

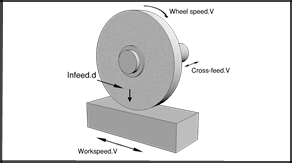

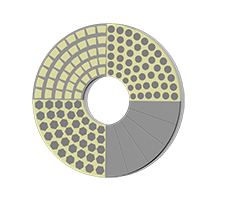

Improve the heat dissipation ability, and reduce the problems of passivation of abrasive particles and failure to discharge abrasive debris

The speed of the grinding wheel should not be too fast, the supply of cutting fluid needs to be sufficient, and special attention must be paid to the removal of grinding debris. Through dressing methods, these require operators with sufficient experience and careful operation to achieve. The best method It is possible to solve these problems at once by making enough porosity on the grinding wheel.

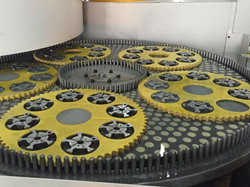

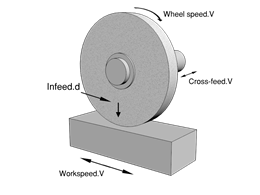

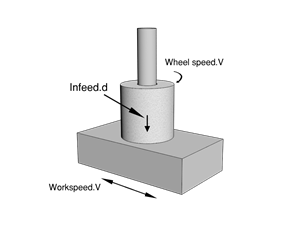

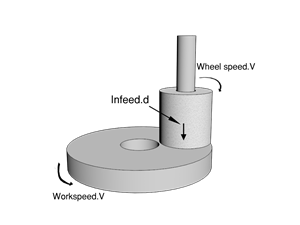

The case of surface grinding

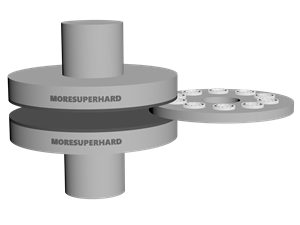

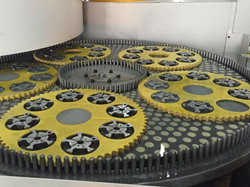

1. Powder metallurgy inner rotor double face grinding

a. Introduction to powder metallurgy inner rotor:

The workpiece is powder inner rotor material of powder metallurgy, the size is Diameter 71.8mm x height 19.2mm.

b. Powder metallurgy inner rotor grinding results:

Parallelism/flatness 0.006 mm; verticality 0.02 mm; roughness Ra 0.8 μm; thickness tolerance ± 0.01 mm; stock removal 0.1 mm.