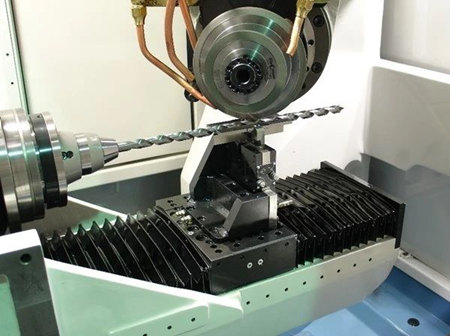

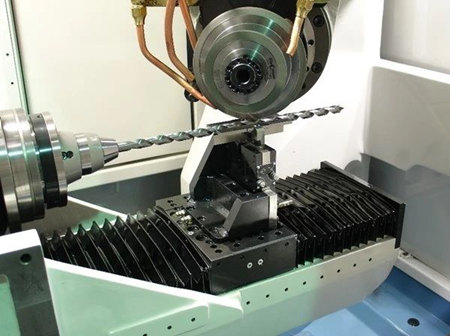

TX7 Linear is the new industry benchmark for production grinding and machining of cutting tools and components. With its large working envelope and powerful grinding spindle, TX7 Linear will deliver precision and productivity across the widest range of applications.

TX7 Linear finds the perfect balance between proven designs combined with ANCA’s newest technologies. The rigid bisymmetrical column design on the solid polymer concrete base has been the foundation design of ANCA machines over the years. Now, in addition, ANCA’s new LinX cylindrical linear motors and linear glass scales are fitted as standard on X, Y and Z for proven and unsurpassed long term reliability and accuracy. The result is a superior machine that ensures customers will meet ever increasing market demands of precision CNC tool grinding, no matter the industry.

What is deep hole drilling?

Deep hole drilling is a process of drilling holes in metal with a high depth to diameter ratio on a CNC machine tool. In a common drilling process, the depth of a hole is less than five times its diameter. If the depth to diameter ratio exceeds five, the process is called deep hole drilling. Deep hole drilling tools range in diameter from 1 mm to 200 mm [0.04 inches to 8.00 inches] and require the use of special drills with penetrating cooling holes to deliver high-pressure coolant to assist in chip evacuation, allowing the cutting to achieve the required tolerances and surface finish.

Some common deep hole drilling processes include gun drilling, BTA drilling (boring and nesting association) and traditional carbide Fried Dough Twists drills. These processes are suitable for different apertures and tolerances, and play their respective advantages in deep hole drilling.

BTA drilling is an effective deep hole drilling process because it is more environmentally friendly, reliable, and capable of achieving larger diameters at higher feed rates. BTA drilling is effective in 20 – 200 mm [0.80 – 8.00 inch] holes, and its size range is larger than that of gun drill and carbide Fried Dough Twists drill.

On the TX7, Straits requested the addition of the P-axis travel support option. This feature provides different tool support for both applications. During acceptance of the grinder, ANCA engineers demonstrated how to quickly configure, from a fixed tailstock suitable for hip file applications to a traveling bracket that can meet the needs of elongated reamers.

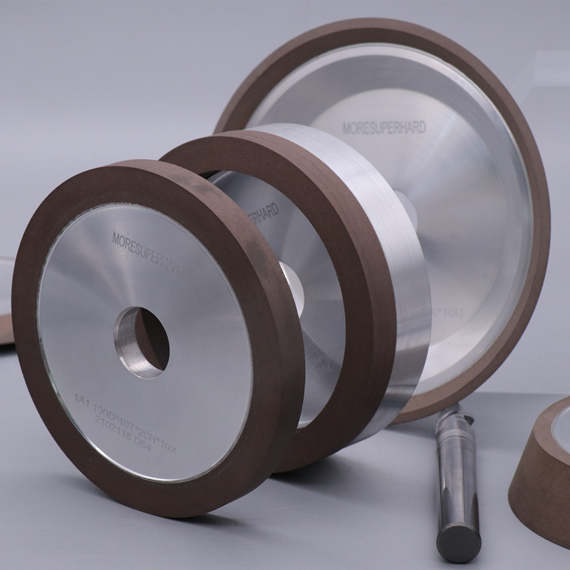

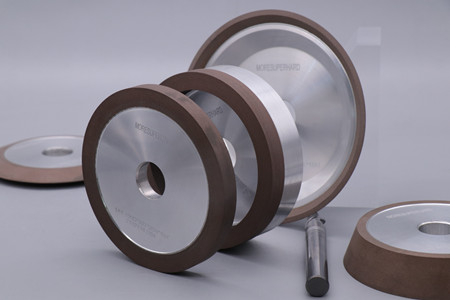

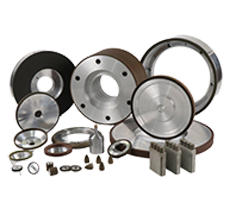

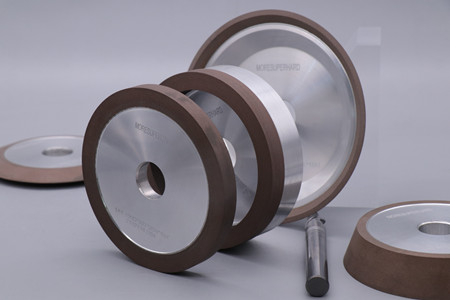

Moresuperhard's grinding solutions for ANCA TX7 Linear Machines:

Resin bond or hybrid bond diamond/CBN grinding wheels for drilling:

Resin CBN grinding wheels are suitable for grinding workpieces such as

hardened steel,

high-speed steel,

cast iron,

stainless steel and

nitrided stainless steel.

At the same time, in order to improve production efficiency, people began to use CBN grinding wheels on low-speed grinding machines to increasingly replace ordinary grinding tools. At present, resin CBN grinding wheels are widely used for

precision grinding of workpieces containing iron group elements in industries or fields such as

automotive, bearings, compressors and precision molds, and have become an irreplaceable tool in manufacturing production and grinding processing.

Moresuperhard's ample models of resin CBN grinding wheels:

► Model: 1A1, 1V1,1E1, 3A1, 14A1, 11V9, 12A2, 12V9, 4B1, 3A1, 14K1, 1B9.