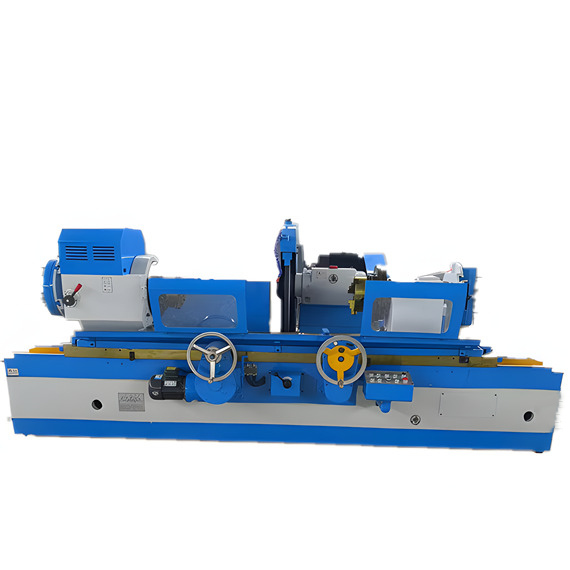

The crankshaft grinding machine Model MQ8260A is intended for use in the automobile. tractor, diesel engine works and their repair shops to grind the journals and crankpins of crankshafts.

Structure features of Moresuperhard manual crankshaft grinding machine:

▇Three different work speeds are obtainable by using the belts in the headstock.

▇Cross chucks are used in the headstock and tailstock.

▇Friction coupling is used in the headstock transmission chain for its easy adjustment.

▇Table traverse is operated either by hand or by power.

▇Wheelhead rapid approach and withdrawal are effected through hydraulic means.

▇Wheelhead rapid approach and withdrawal are effected through hydraulic means.

▇The wheel spindle being 80mm in diameter has good rigidity and strength.

▇Use is made of roller ways for wheelhead movement.

▇The bed ways and wheelhead are lubricated in an automatic cycle by means of the oil pump.

Basic accessories of Moresuperhard manual crankshaft grinding machine:

Coolant tank 1 set

Left and right chucks 1 set each

External cylindrical dresser 1 set

Grinding wheel end face dresser 1 set

Vertical template 1 set

Horizontal template 1 set

Machine pad iron 11 sets

Grinding wheel arc dresser 1 set

Measuring bridge 1 set

Special accessories

Grinding wheel balance frame 1 set

Calibration device 1 set

Crankshaft Grinding - Vitrified CBN Grinding Wheel

.jpg) ► Application: grinding crankshaft

► Application: grinding crankshaft

► Model : 1A1 CBN wheel

► Wheel speed is generally 80m/s-120m/s

Vitrified CBN grinding wheel are remarkable for preventing grinding burns to the shoulder of the Crankshaft. CBN Grinding Wheel For Crankshaft can equip with various high precision CNC Crankshaft Grinding Machines, Suitable for high efficient,heavy grinding of Crankshaft pin grinding,Journal grinding.The wheel speed is generally 80m/s-120m/s.

.jpg)

.jpg)