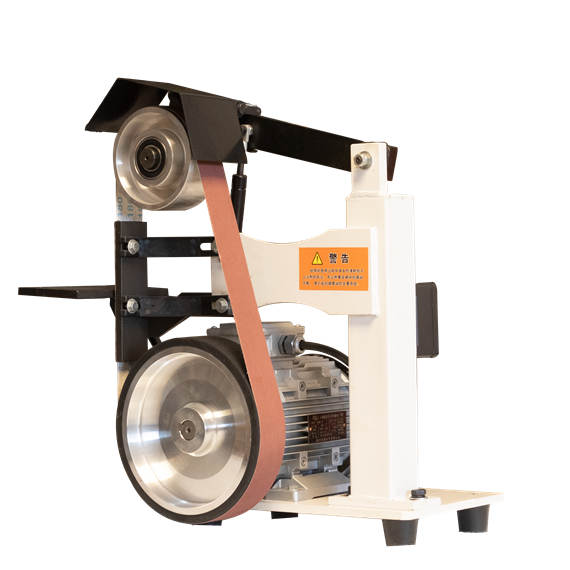

Belt Sander with diamond resin/electroplated abrasive film belt, mainly used for surface dyeing (CrN), Grinding of titanium nitride (TiN), titanium carbide (TiCN), tungsten carbide and other ceramic coated rolls and shafts Cutting and polishing.

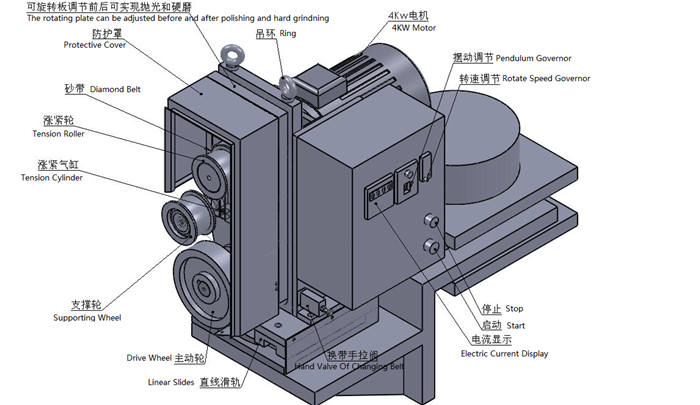

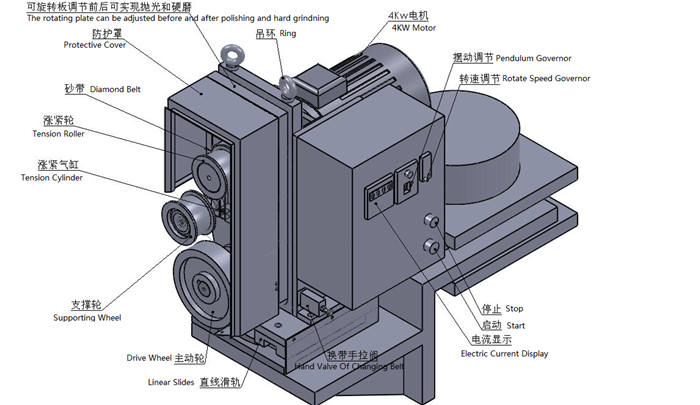

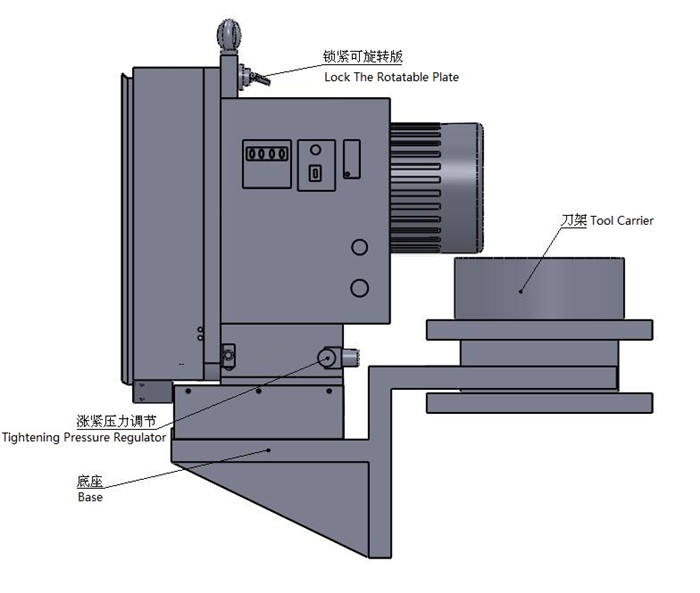

Schematic diagram of the belt sander:

Main technical parameters of belt sander

1. The main bracket of the belt machine is made of 30mm thick steel plate.

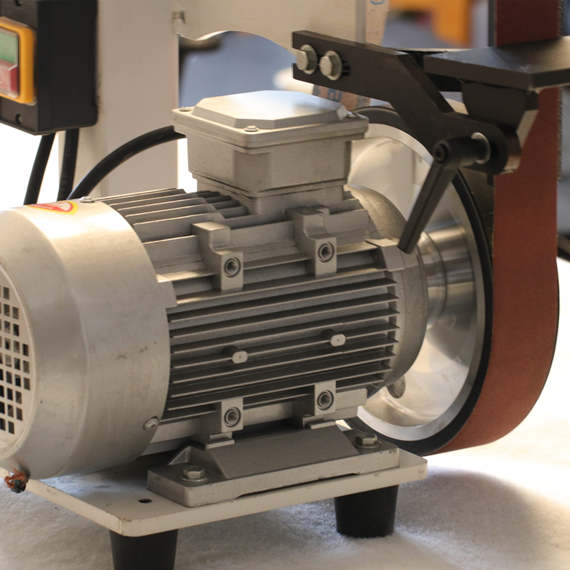

2. The power adopts Xinling brand motor with a power of 4 kilowatts.

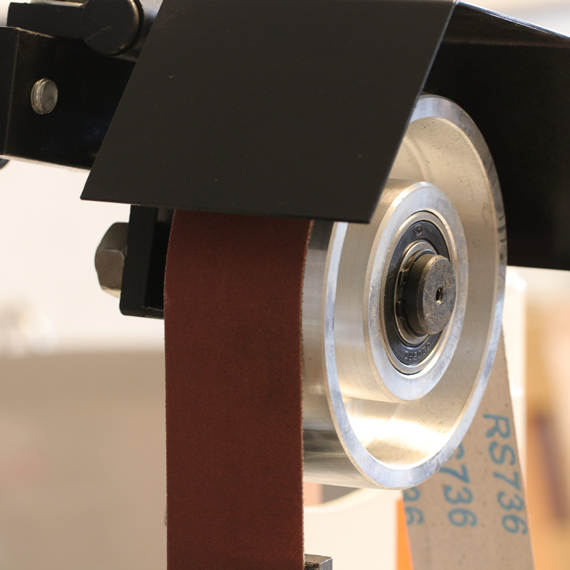

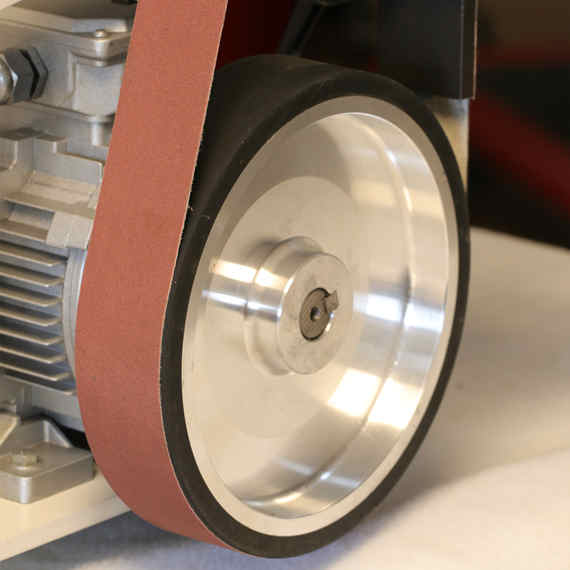

3. The driving wheel adopts packing rubber wheel, the outer diameter is 200mmx50mm wide

4. The sand belt tightening almond adopts Sanzheng brand.

5. The outer cover is made of stainless steel wire drawing board. 6. Belt size 1200mm long x50mm wide 7. Belt machine mass: 180 kg 8. The frequency converter adopts Delta brand 9. The left and right swing is realized by the motor driving the eccentric shaft on the linear slide rail.

Using Method of Moresuperhard Belt Sander :

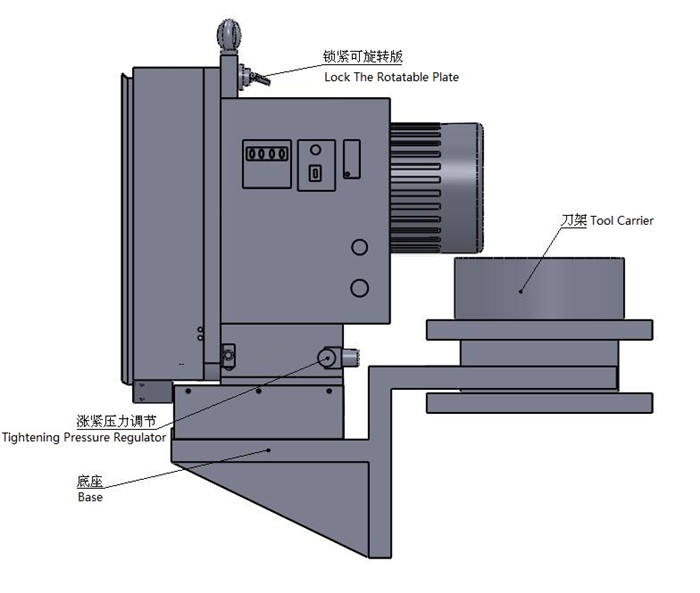

1. When working, first use a crane to take out the lathe tool holder from the lathe slide box, and then use a crane to lift the belt machine

installed on the same position of the lathe slide box, and at the same time, the base must be fixed on the lathe slide with 4 screws.

on the crate. (The center height of the abrasive belt grinding head is 178mm, if the center height is wrong, a base needs to be added.)

2. Pull the manual pressure valve, install the diamond abrasive belt when the cylinder is at the bottom, and turn the rubber working wheel counterclockwise by hand to check

Check whether the abrasive belt is running off. When using for the first time, choose 200#~400# gold according to the surface roughness of the sprayed product.

Corundum abrasive belt for rough polishing.

3. Turn on the power (check that the rubber working wheel rotates counterclockwise) the gas source (gas pressure P/0.4-0.6MPa)

And cooling water (just clean water).

4. Install the processed workpiece (roller or shaft) and adjust the geometric state (concentricity) of the workpiece.

5. Adjust the working surface of the diamond abrasive belt on the rubber working wheel to be parallel to the axis of the workpiece to be processed (the abrasive belt must be adjusted

machine bottom plate screws), and then tighten the belt sander bottom plate screws.

6. Turn on the cooling water and compressed gas in sequence. Turn on the power switch of the belt grinder, and press the run key to adjust the electrode speed.

The motor rotates and runs for 1 minute without load until the current display remains unchanged. The current is generally 0.7-0.9 during grinding

(depending on the amount of grinding), the speed is adjusted to 30-0Hz

7. Walk for a while to open the swing.

8. The upper locking handle can realize wheel contact and soft contact

9. The lathe makes the workpiece rotate in the opposite direction to the direction of the abrasive belt.

Using Method of Moresuperhard Belt Sander :

1. When working, first use a crane to take out the lathe tool holder from the lathe slide box, and then use a crane to lift the belt machine

installed on the same position of the lathe slide box, and at the same time, the base must be fixed on the lathe slide with 4 screws.

on the crate. (The center height of the abrasive belt grinding head is 178mm, if the center height is wrong, a base needs to be added.)

2. Pull the manual pressure valve, install the diamond abrasive belt when the cylinder is at the bottom, and turn the rubber working wheel counterclockwise by hand to check

Check whether the abrasive belt is running off. When using for the first time, choose 200#~400# gold according to the surface roughness of the sprayed product.

Corundum abrasive belt for rough polishing.

3. Turn on the power (check that the rubber working wheel rotates counterclockwise) the gas source (gas pressure P/0.4-0.6MPa)

And cooling water (just clean water).

4. Install the processed workpiece (roller or shaft) and adjust the geometric state (concentricity) of the workpiece.

5. Adjust the working surface of the diamond abrasive belt on the rubber working wheel to be parallel to the axis of the workpiece to be processed (the abrasive belt must be adjusted

machine bottom plate screws), and then tighten the belt sander bottom plate screws.

6. Turn on the cooling water and compressed gas in sequence. Turn on the power switch of the belt grinder, and press the run key to adjust the electrode speed.

The motor rotates and runs for 1 minute without load until the current display remains unchanged. The current is generally 0.7-0.9 during grinding

(depending on the amount of grinding), the speed is adjusted to 30-0Hz

7. Walk for a while to open the swing.

8. The upper locking handle can realize wheel contact and soft contact

9. The lathe makes the workpiece rotate in the opposite direction to the direction of the abrasive belt.

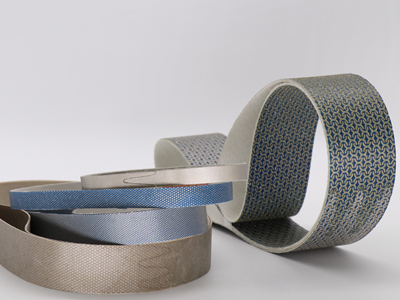

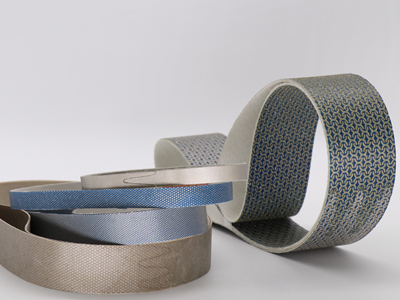

Applicable Moresuperhard's Diamond & CBN Sanding Film Belts:

► Bond: Metal nickel plating electroplated bond & Resin bond (resin bond also consists of flexible and hard type)

► Length: 150mm - 5000mm

► Width: 5mm - 350mm

► Grit: #60,#100,#120,#200,#400,#800,#1500,#2000,#3000,#5000

Electroplated Bond Diamond Abrasive Belt:

.jpg) ► Resin Bond Diamond Abrasive Belt

► Resin Bond Diamond Abrasive Belt

.jpg)