Compact Structure of Moresuperhard Peripheral Grinding Machine

.jpg)

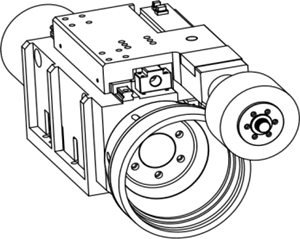

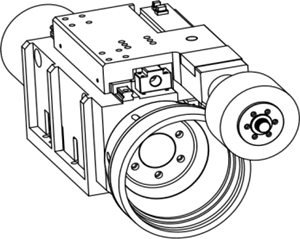

The compact mechanical structure design and the wide application of advanced manufacturing technology further reduce the footprint of the machine tool, which means that the output per unit area increases and improves the competitiveness of the owner.

Affordable Peripheral Grinding Machine

Ultra-cost-effective, for peripheral grinding, standard internal in-line grinding wheel dressing, suitable for grinding a variety of materials

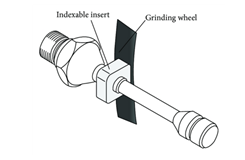

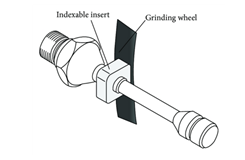

The application of indexed insert, X, Y, B axis direct drive technology and permanent magnet synchronous electric spindle makes the machine tool have high dynamic characteristics and rigidity, smooth grinding arc transition, good cutting edge quality , and is a sharp weapon for mass production.

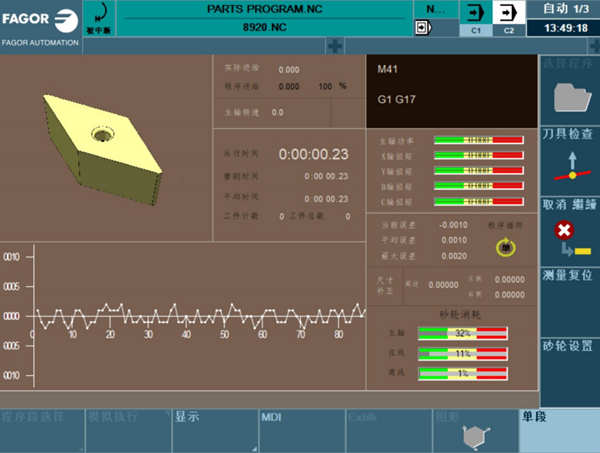

Overview of Each Axis in the Moresuperhard Peripheral Grinding Machine

X-axis, grinding wheel longitudinal feed axis, linear motor, absolute grating ruler, full closed-loop control

Y-axis, grinding wheel lateral feed axis, linear motor, absolute grating ruler, full closed-loop control

B-axis, workpiece spindle rotary motion, direct drive motor with absolute encoder, full closed-loop control

C-axis, High precision CNC turntable turntable

U-axis In-line cleaning axis servo control

Advanced Direct Drive Technology of the Moresuperhard Peripheral Grinding Machine

The main feed shafts involved in grinding X, Y, and B axes adopt advanced direct drive technology, and the high-torque direct drive motor with absolute value full closed-loop feedback ensures the rapid response and high-speed operation of each axis to achieve high-precision and high-efficiency machining.

Permanent Magnet Synchronous Electric Spindle in the Moresuperhard Peripheral Grinding Machine

The grinding wheel spindle adopts permanent magnet synchronous electric spindle technology, and its unique constant torque control enables the spindle motor to ensure constant torque no matter what speed it works at, and ensures the optimal rigidity, seismic resistance and durability of the spindle mechanism.

6-joint manipulator in the Moresuperhard Peripheral Grinding Machine

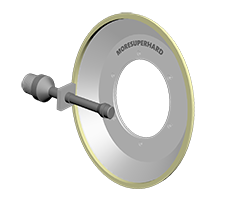

Applicable Grinding wheels for the Moresuperhard Peripheral Grinding Machine

Applicable Grinding wheels for the Moresuperhard Peripheral Grinding Machine

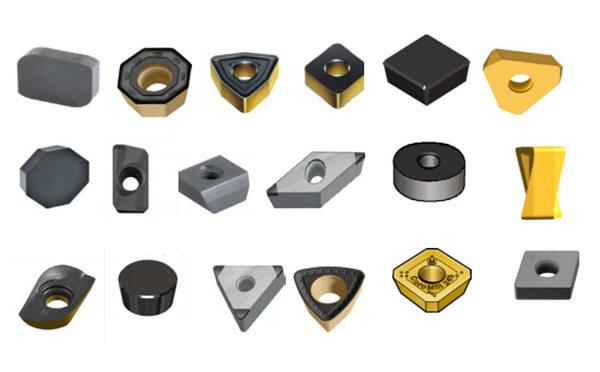

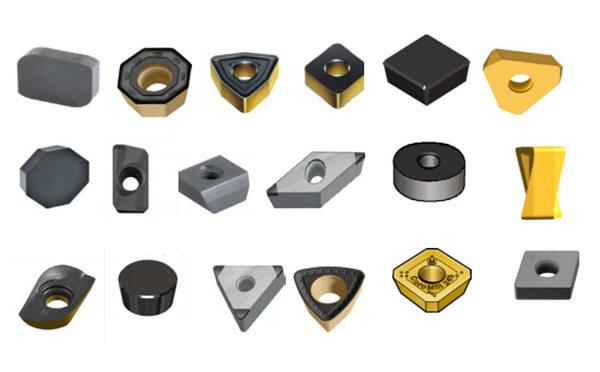

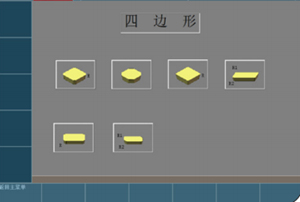

► Grinding Indexable inserts (tungsten carbide inserts, ceramic inserts, CBN inserts)

► Model: 6A2T, 6A2M, 11A2B, 12A2T

► Grinding Machine: WENDT, WAIDA, AGATHON, EWAG, COBORN, etc.

.png)

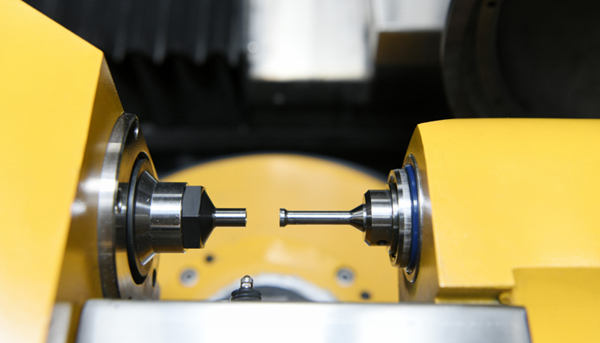

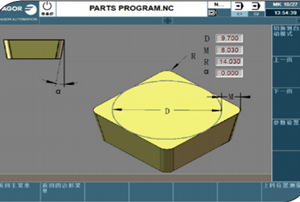

The 400mm large grinding wheel makes the grinding process more stable, and different shapes of grinding wheel flanges can be selected according to the products to be ground.

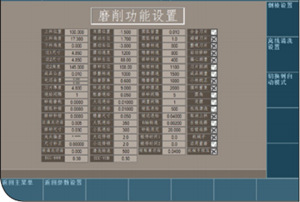

Grinding Dressing Wheels for the Moresuperhard Peripheral Grinding Machine

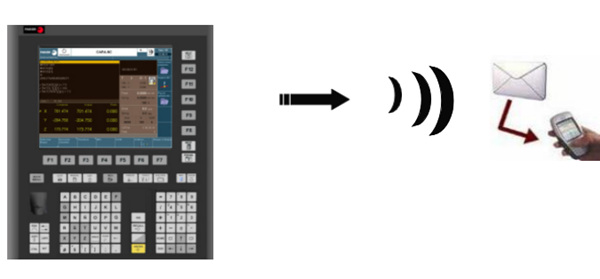

Measuring Method:

Blade size measurement system for automatic alignment, position correction, measurement and compensation of dimensions.

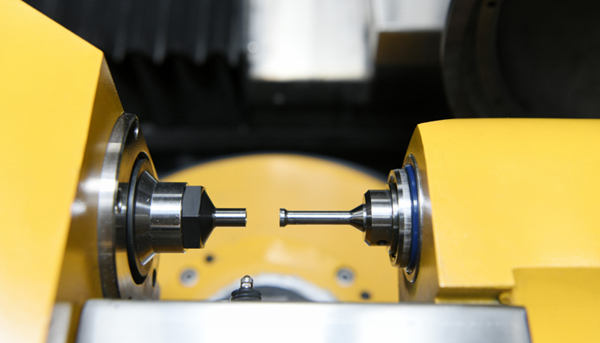

Typical Product of Manufacture:

.jpg)

.png)