Die and mold machining needs to consider several key factors when selecting a surface grinder to ensure that the equipment selected will meet specific machining needs while improving productivity and quality. Below are a few key issues to keep in mind when selecting a surface grinder:

.jpg)

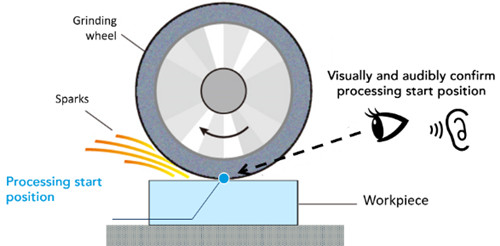

Machining needs of surface grinding machine:

First, the size, shape, accuracy requirements and material type of the mold need to be specified. For large molds, it may be necessary to select a surface grinder with a large working table and sufficient power. For molds with high precision requirements, a surface grinder with a high-precision spindle, high-precision measurement system and advanced control technology should be selected.

Precision and Stability of surface grinding machine:

The precision and stability of the surface grinder directly affects the processing quality of the mold. A high precision and stable grinder can ensure the precision and surface quality of the mold. Therefore, when choosing a grinder, attention should be paid to its accuracy level, spindle runout, table movement accuracy and other parameters.

Degree of automation of surface grinding machine:

Modern surface grinding machines are equipped with a variety of automation functions, such as automatic feeding, automatic dressing of grinding wheels, automatic control of coolant and so on. These functions can improve productivity, reduce manual intervention, and lower the difficulty of operation. Therefore, when choosing a grinder, you should consider whether you need these automation functions according to the actual needs.

Grinder brand and after-sales service of surface grinding machine

choosing a surface grinder of a well-known brand usually means higher quality and more reliable after-sales service guarantee. After-sales service includes installation and commissioning, maintenance, repair support and spare parts supply. When purchasing a grinder, you should know the supplier's service and support policy to ensure that you can get timely and effective support during use.

Cost-effective of surface grinding machine:

When choosing a surface grinder, you need to comprehensively consider the performance of the equipment, price and their own budget. Under the premise of meeting the processing needs, should choose a cost-effective grinding machine to maximize the return on investment.

In summary, mold processing in the choice of

surface grinding machine, you need to comprehensively consider the processing needs, accuracy and stability, degree of automation, brand and after-sales service, as well as cost-effective and other factors. By carefully evaluating and comparing the performance and characteristics of different grinders, you can choose the most suitable surface grinder for your needs, thus improving the productivity and quality of mold processing.

.jpg)