In the sophisticated world of grinding, wheel clogging is an invisible adversary that often inadvertently strikes at machining efficiency and workpiece quality. Have you ever encountered such a problem, grinding wheel clogging makes the process tricky?

Today, we analyze the reasons.

First of all, what are the factors that cause clogging of the grinding wheel itself?

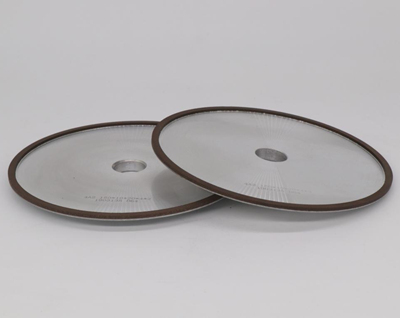

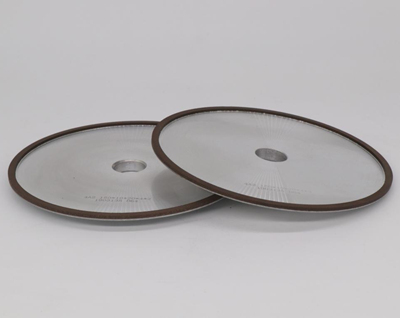

1. the type of grinding wheel abrasive

Different types of abrasives have different effects on the cutting performance of the wheel and the degree of clogging. Choose the right type of abrasive can effectively reduce the clogging of the grinding wheel.

2. grinding wheel hardness

Wheel hardness is too high, the abrasive grain is not easy to fall off, easy to form a blockage; hardness is too low, the abrasive grain is easy to fall off, but the cutting performance decreases. Therefore, according to the processing requirements need to choose the appropriate grinding wheel hardness.

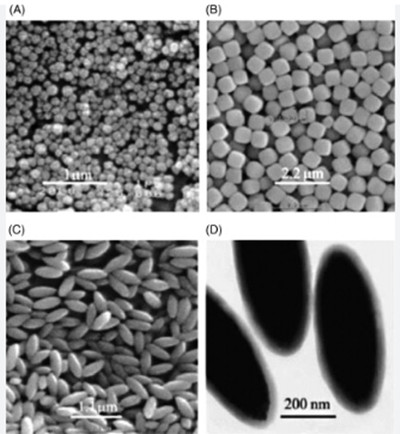

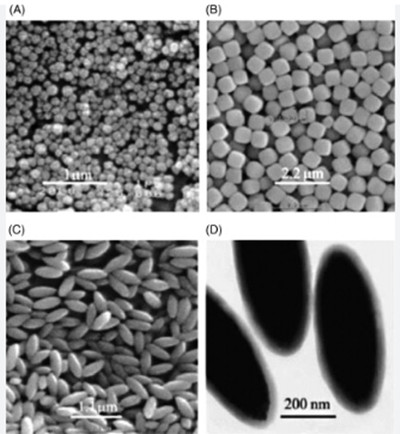

3. grinding wheel particle size

the finer the particle size, the greater the number of abrasive grains, the smaller the distance between the cutting edge, easily lead to clogging. But the particle size is too coarse, cutting performance will decline. Therefore, according to the processing requirements need to choose the appropriate grinding wheel size.

4. grinding wheel organization

grinding wheel organization reflects the proportion of abrasive, binder, porosity relationship between the three. Organization is too dense, the gap between the abrasive grain is small, easy to block; organization is too loose, the gap between the abrasive grain is large, cutting performance is poor. Therefore, it is necessary to choose a suitable grinding wheel organization.

So, in the process of grinding, which grinding conditions will affect the generation of grinding wheel blockage problems?

1. grinding wheel linear speed

1. grinding wheel linear speed

grinding wheel linear speed is too low, the depth of cut of the abrasive grains is large, easy to produce clogging; linear speed is too high, the depth of cut of the abrasive grains is small, but the grinding heat increases, may also lead to clogging. Therefore, the need to choose the appropriate grinding wheel speed.

2. workpiece speed

when the workpiece speed is too fast and the depth of cut of the abrasive grain is shallow, it is more likely to clogging phenomenon. Because the abrasive grain on the surface of the workpiece to stay a short period of time, grinding down the chips may not be too late to be discharged, so as to accumulate in the abrasive grain between or on the surface of the grinding wheel.

3. radial access:

If the radial access is too large, the grinding force increases, grinding heat rises, easy to clog; access is too small, low grinding efficiency. Therefore, the need to control the appropriate amount of radial cut.

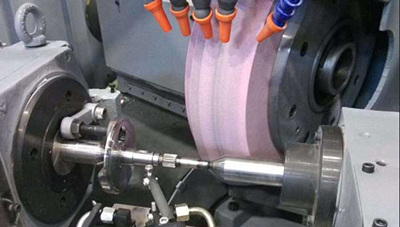

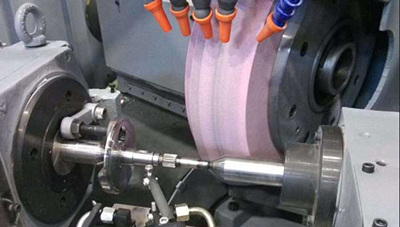

4. grinding mode

different grinding mode on the grinding wheel clogging degree has different effects. For example, plunge-cut grinding is easier to block than longitudinal grinding. This is because in plunge grinding, the contact area between the grinding wheel and the workpiece is relatively large, and the cutting edge of the abrasive grain needs to be rubbed several times on the same grinding mark, which increases the possibility of heat generation and the temperature of the grinding area. In addition, the increased difficulty of the coolant entering the grinding zone makes it difficult for the heat in the grinding zone to be effectively dispersed, which leads to the accumulation of grinding heat and increased clogging between the abrasive grains. Therefore, it is necessary to choose the appropriate grinding method according to the processing requirements.

5. grinding temperature

grinding temperature is too high, the workpiece material and grinding wheel surface is prone to adhesion, the formation of adhesion-type blockage. Therefore, it is necessary to control the grinding temperature to avoid too high.

6. grinding fluid

the type of grinding fluid, concentration, flow and other factors will affect the degree of clogging of the grinding wheel. Choosing the right grinding fluid can effectively reduce wheel clogging.

Through the in-depth analysis of the causes of wheel clogging, it is not difficult to find, whether it is the characteristics of the wheel itself or the setting of the grinding conditions, have a direct impact on the problem of wheel clogging. Only by understanding these reasons, we can find effective countermeasures to reduce the incidence of wheel clogging and improve processing efficiency and workpiece quality. In practice, we should combine the specific processing conditions and workpiece requirements, flexible adjustment and optimization of the solution, so that wheel clogging is no longer a problem in the grinding process.