We need to have a full understanding of the machinery industry of the various types of processing equipment, processing scope of application, structural characteristics, processing accuracy, etc., but also need to combine the company's equipment specifics, a variety of different processing parts and processing procedures for reasonable equipment selection and use. Understanding of their own processing advantages, but also clear about their own processing disadvantages, to be able to make good use of their strengths and weaknesses to coordinate the company's machining work.

Machining industry's most common lathe, milling, planing, grinding, boring, drilling, wire cutting and other processing equipment, followed by a detailed introduction to the different types of equipment, scope of application, structural characteristics and processing accuracy.

1 Lathe Machine

01 Types of lathe Machine

Type of lathe is very much, according to a machining technician manual statistics up to 77 kinds of more, more typical categories are: instrumentation lathe, single-axis automatic lathe, multi-axis automatic or semi-automatic lathe, back to the wheel or turret lathe, crankshaft and camshaft lathe, vertical lathe, floor and horizontal lathe, profiling and multi-tool lathe, axle roller spindle and shovel teeth lathe, etc., which is divided into many small classified, the number of vary, and in our machinery industry is more commonly used in the vertical lathe and horizontal lathe, almost any mechanical processing places can see the figure of these two kinds of lathes.

02 The scope of application of lathe processing

We mainly choose a few typical types of lathes to introduce the scope of use of processing.

A, horizontal lathe, can be applied to turning internal and external cylindrical surfaces, conical surfaces, forming rotary surfaces and ring grooves, turning section and a variety of threads, can be drilling, reaming, reaming, tapping threads, sets of threads and knurling and other processing procedures. Although the degree of automation of the ordinary horizontal lathe is low, the processing of auxiliary time is also more, but because of its wide range of processing and good general performance, this type of machine tool in the machining industry has been widely used and popularized, is one of the typical representative of our machinery industry on the processing equipment, but also one of the indispensable machining equipment in the machining industry.

B. Vertical lathe is suitable for the processing of various racks and shell parts, as well as the processing of internal and external cylindrical surfaces, conical surfaces, end surfaces, grooves, cutting off and drilling, expanding and reaming holes, etc. With the help of additional devices, it can also be used to realize the machining process of turning threads, turning end faces, profiling, milling and grinding.

Machining accuracy of lathe

A. The machining accuracy of the usual horizontal lathe is as follows:

Roundness: 0.015mm; cylindricity: 0.02/150mm; flatness 0.02/¢150mm; surface roughness: 1.6Ra/μm.

B. The machining accuracy of vertical lathe is as follows:

Roundness: 0.02mm; cylindricity: 0.01mm; flatness 0.03mm.

The above machining accuracy is only a relative reference value, does not mean that all lathes are in line with many lathe equipment according to the manufacturer's specific requirements and assembly specifics have a certain amount of up and down, but no matter how much the amount of fluctuation, the machining accuracy value must be to meet the requirements of the national standard of this type of equipment, if in the purchase of the equipment, the machining accuracy requirements do not meet the requirements of the National Standard The purchaser has the right to refuse acceptance and payment.

2. Milling machine

01 type of milling machine

Type of milling machine is also complex and diverse, according to a machining technician manual statistics up to more than 70 kinds, the more typical categories are: instrumentation milling machine, cantilever and ram milling machine, gantry milling machine, plane milling machine, profiling milling machine, vertical lifting table milling machine, horizontal lifting table milling machine, bed milling machine, milling machine, tools, etc., which is divided into a lot of small classifications, the number of varying, and more commonly used in our machinery industry Vertical machining centers and gantry machining centers, almost any mechanical processing places can see these two types of milling machines, we also target these two typical milling machines to do a general introduction and analysis.

02 Scope of application of milling machine

Because there are too many types of milling machines and structures, and applicable to a wide range of degrees are also very different, so we refer to the most commonly used vertical machining centers and gantry machining centers for two typical milling machines to do a processing range of introduction.

A, vertical machining center (pictured above), vertical machining center is actually a vertical CNC milling machine with a tool magazine, its main feature is the use of multi-flute rotary tool for cutting, can be flat, groove, split tooth parts, spiral surface and a variety of curved surfaces, especially with the application of CNC technology, the processing range of this type of machine tool has also been greatly enhanced, in addition to a variety of milling operations. Can also workpiece drilling, boring, reaming and tapping threads and other composite processing, has a very wide range of practicality and popularization significance.

B, gantry machining centers, and vertical machining centers compared to the gantry machining centers that is CNC gantry milling machine plus tool magazine composite application, in the processing range, gantry machining centers have almost all the machining capabilities of ordinary vertical machining centers, and in the external dimensions of the parts to adapt to the processing of larger tools, and also in the machining efficiency and machining accuracy also has a very big advantage, especially five-axis linkage type The practical application of gantry machining centers, its processing range has also been greatly enhanced, laying the foundation for the development of China's manufacturing industry in the direction of high precision.

03 milling machine machining accuracy

A, vertical machining center:

Flatness: 0.025/300mm; Rough superlative: 1.6Ra/μm.

B, gantry machining center:

Flatness: 0.025/300mm; roughness: 2.5Ra/μm.

The above machining accuracy is only a relative reference value, does not mean that all milling machines are in line with many milling machine equipment according to the manufacturer's specific requirements and assembly of the specific circumstances have a certain amount of up and down, but no matter how much the amount of fluctuation, the machining accuracy of the value of the equipment must meet the national standard requirements for this type of equipment, if in the purchase of the equipment, the machining accuracy of its requirements do not meet the requirements of the National Standard The purchaser has the right to refuse acceptance and payment.

3. Planing machine

01Types of planer

Relative to lathe and milling machine, planer type is much less, also according to the statistics of machining technician manual there are about 21 kinds, the more typical types are: cantilever planer, gantry planer, bullhead planer, edge and mold planer, etc., and these categories are divided into a lot of small types of planer products, and we in the machinery industry the highest rate of use, the most widespread should belong to the bullhead planer and the gantry planer. As shown in the above figure, we will do a basic analysis and introduction for these two typical planers.

02 Scope of application of planer

The planing movement of planer is mainly the cycle round-trip linear movement relative to the processing workpiece, and the applicable features of the planing parts are mostly the processing of plane, inclined and concave-convex surfaces, and the planing can also be carried out for various curved surfaces, but because of the limitation of its own processing characteristics, the processing speed of planing is not too high, and the planing knife of the return stroke does not participate in the processing and cutting of the parts, which results in the loss of the empty stroke, and the processing efficiency is comparatively low. Efficiency is relatively low.

At the same time with a variety of other processing equipment, numerical control and automation aspects of the great technological enhancement, planing processing method has been in the edge of gradually be replaced, from now on a lot of equipment upgrading towards the point of view, this type of processing machine tools and did not get a great upgrading of innovation, a large part of the original still stays in the original structure and layout, especially vertical machining centers and gantry machining centers, and processing tool innovation, is more As well as the continuous innovation of processing tools, it has greatly replaced the processing advantages of planer in the processing range, which puts the equipment with relatively low processing efficiency in a very embarrassing situation.

03Processing precision of planer

The machining accuracy of planer can generally reach IT10-IT7 accuracy level, especially for the processing of long guideway surface of some large-scale machine tools can even replace the grinding processing, which is the so-called “fine planer instead of fine grinding” processing mode.

4. Grinding machine

01Types of grinding machines

Relative to the first few types of processing equipment, the types of grinding machines is even more numerous, according to a machining technician's manual of statistics about 194 kinds of more than one, from the major categories can be divided into: instrumentation grinder, cylindrical grinder, internal grinder, grinder, coordinate grinder, guideway grinder, tool edge grinder, surface and face grinder, crankshaft camshaft spline and roller grinder, tool grinder, ultra-precision machine, internal honing machine, Cylindrical and other honing machines, polishing machines, belt polishing and grinding machines. Tool sharpening and grinding machine tools, indexable insert grinding machine tools, lapping machines, ball bearing collar groove grinding machines, roller bearing collar raceway grinding machines, bearing collar super-finishing machines, blade grinding machine tools, roller machining machine tools, steel ball machining machine tools, valve piston and piston ring grinding machine tools, automobile and tractor regrinding machine tools, and many other types of machine tools, because the classification of the grinding machine and should be too wide, and many grinding machines are industry-specific Some specific equipment, so we refer to the grinding machine in the machinery industry has a general usability to do a basic introduction, in this article, we mainly choose the cylindrical grinding machine and surface grinding machine to do a brief description.

02 grinding machine processing scope of application

A, cylindrical grinding machine, cylindrical grinding machine is mainly processing cylindrical surface, conical surface or other rotating body of the outer surface and shoulder end face, because of its better processing adaptability and processing accuracy, is widely used in machining some of the high-precision parts processing, especially in the final finishing process is more commonly used in these parts, which can not only maximize the guarantee of geometric dimensions of the parts processed, and at the same time also be able to achieve a better surface finish. Realize a better surface finish requirements, so it is one of the indispensable equipment in the machining process.

B, surface grinding machine, which is mainly used for processing plane, step surface, side and other parts surface, in the machinery industry is also very widely used, especially in some high-precision parts surface processing, grinding machine is almost the last guarantee of machining accuracy of the unquestionable choice, is also because of this, the use of surface grinding machine is the majority of grinding operator's required courses, and even in some equipment assembly industry, the use of surface grinding machine is also the standard skills of assembly personnel. Even in some equipment assembly industries, the use of surface grinder is also the standard skill of assembly personnel, because the grinding of various adjustment pads in the assembly process rely on surface grinder to complete.

03 Machining accuracy of grinding machines

A. Machining accuracy of cylindrical grinding machine:

Roundness and cylindricity: 0.003mm; surface roughness: 0.32Ra/μm.

B. Machining accuracy of surface grinder:

Parallelism: 0.01/300mm; surface roughness: 0.8Ra/μm.

From the above machining accuracy, we can also clearly see that, compared with the front of the lathe, milling machine, planer and other processing equipment, grinding machine is more capable of achieving a higher behavioral tolerance accuracy and surface roughness, so in many parts of the finishing process, the grinding machine is widely and commonly used.

5. Boring Machine

01 type of boring machine

Compared to the previous types of processing equipment, boring machine also belongs to a relatively small number of a kind of processing equipment, according to a machining technician manual statistics about 23 kinds of about, from its broad categories can be divided into the following kinds: deep hole boring machine, coordinate boring machine, vertical boring machine, horizontal milling and boring machine, fine boring machine, automotive tractor repair boring machine, etc., which in our machinery industry is the most common and the most commonly used boring machine should fly! Coordinate boring machine belongs to, below we also on the coordinate boring machine some features to do a brief introduction and analysis.

02 Boring machine processing scope of application

Boring machine types are varied, we on the coordinate boring machine to do a brief introduction, you can touch accordingly to learn other types of boring machine knowledge, coordinate boring machine is a precision machine tool with precision coordinate positioning device, mainly used for boring size, shape and positional accuracy requirements of the hole system, can be drilled, reamed, reamed, 鍯 end face, groove, milling surface and other processing, but also can carry out Coordinate measurement, precision scaling and engraving and other work, has a very wide range of reliable processing characteristics.

But with the vigorous development of CNC technology, especially CNC vertical milling machine and CNC horizontal milling machine, boring machine this once hole system processing equipment in the overlord, there is a danger of gradual replacement, of course, there is an objective side of the irreplaceable, but no matter what the demise of the equipment or the development of the machining industry is a kind of progress, it is technological progress, is the progress of technology, but also is the progress of the process is the progress of our country's manufacturing industry. The progress of our country's manufacturing industry.

03 Boring machine machining accuracy

Coordinate boring machine processing hole accuracy is generally IT6-7 level, surface roughness of 0.4-0.8Ra/μm.

6. Drilling machines

01 type of drilling machine

This is the most widely used processing equipment in the machinery industry, but where a mechanical processing plant, basically will have a, if even this processing equipment are not, you are embarrassed to say that you are dry processing, according to a mechanical machining processor manual statistics about 38 kinds of about, according to the major categories can be divided into the following types: coordinate boring drilling machine, deep hole drilling machine, rocker arm drilling machine, desktop drilling machine, vertical drilling machine, horizontal Drilling machine, milling drilling machine, center hole drilling machine, etc., and we use the most common in the machinery industry is the rocker arm drilling machine, just our machining industry standard, no this equipment, you basically can't do the industry, and because of this, we next focus on this drilling machine.

02 drilling machine processing scope of application

We are mainly on the rocker arm drill to illustrate, for this machine tool, here I have only one sentence, is to drill all types of holes, in addition to drilling can also be achieved by reaming, reaming, 鍯 holes, tapping and other machining processes, but there is a big problem, that is, the positional accuracy of the hole system is not high, so for some of the hole system positional accuracy of the parts that require a high degree of accuracy, we usually do not choose to realize the drilling machine.

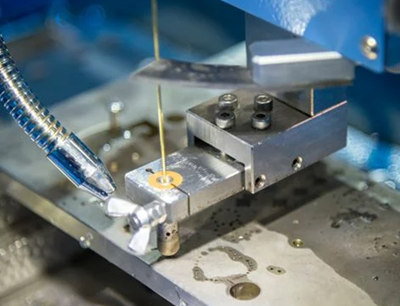

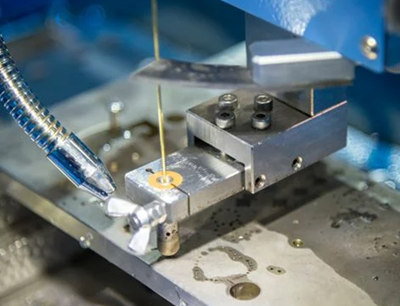

7. Wire Cutting Machine

For wire cutting this processing equipment, I do not have a lot of contact, so there is not a lot of accumulation in this area, but also did not go to do a lot of homework, so the breadth of the use of the mechanical industry has been limited, but it also has its own unique value of existence, especially for some of the parts of the shaped parts of the material and processing, or the existence of a number of relative advantages, but in view of the low efficiency of the processing and the laser machine. Vigorous development, wire cutting this processing equipment is also gradually wandering on the edge of the industry to be eliminated.

.jpg)