Diamond Grinding Wheel Dressing Machine Function

.jpg)

- During the grinding process, the abrasive grains of the grinding wheel disc are gradually rounded and blunted under the action of friction and extrusion, or when grinding tough materials, the abrasive chips are often embedded in the pores on the surface of the grinding wheel, making the surface of the grinding wheel disc clogged, and finally making the grinding wheel disc lose its cutting ability.

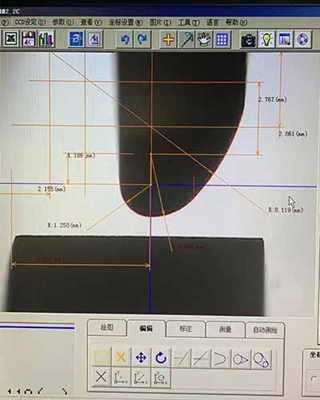

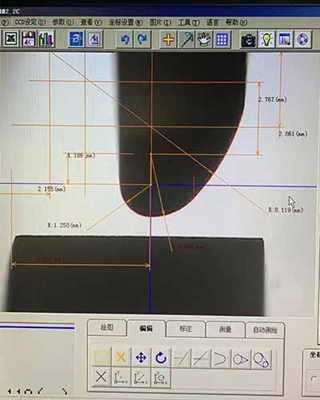

- Wheel dressers utilize their restored shape and cutting ability to dress flat surfaces, angles, arcs and combinations.

Diamond Wheel Dressing Principle

Diamond wheel dressing is divided into two steps: shaping and sharpening. The former is the grinding wheel for micro cutting to ensure the geometric accuracy of the grinding wheel; the latter is in the grinding wheel work for a period of time after the passivation, re-make the cutting micro-edge protrudes from the combination of the agent, and has the appropriate height. Commonly used diamond grinding wheel dressing methods include on-line electrolytic dressing, EDM wheel dressing, cup-shaped grinding wheel dressing, electrolytic-mechanical composite dressing and laser dressing. Among them, GC cup-shaped grinding wheel dressing is more simple, easy to operate, and it is also easier to realize automated dressing.

The actual dressing, bowl-shaped diamond grinding wheel and GC cup-shaped grinding wheel grinding belt staggered fit, with 1:8 linear speed ratio of uniform rotation. The axis of the dressing wheel is fixed, and the diamond grinding wheel makes dressing feed along the axis direction. In this way, the two mutually complete the de-abrasive grinding, grinding off the dulled abrasive, and completing the purpose of dressing sharpening.

Fully Automatic Dressing Control Method of Grinding Wheel

To realize the premise of automatic dressing is automatic monitoring. The first step of the automatic dressing system is to monitor the wear state of the grinding wheel in real time during the whole grinding process. The next step is to set the automatic dressing interval. Depending on the size and material of the processing inserts, the volume to be removed by grinding and the grinding time are different, so the interval should be set taking into account all factors.

The grinding wheel counts the number of times the insert is ground and compares it in real time to the dressing interval set by the system. When the number of grinding times reaches the set number of dressing intervals, the NC program will automatically call the dressing module to realize automatic dressing of the grinding wheel. After dressing, the compensation value of the wheel after dressing is output through data processing.

In order to ensure the safety of machine operation, this system also incorporates real-time monitoring of grinding wheel life and dressing wheel life. If the thickness of the grinding wheel is close to the warning thickness, it will automatically send an alarm signal and stop the machine to wait for the operator to deal with it.

Compensation Methods for Grinding Wheel Dressing

After the grinding wheel is dressed, the abrasive becomes thinner, and the actual contact range of the grinding wheel is bound to change. When grinding again, if the set parameters before dressing are still used, the consistency of the grinding wheel size will be destroyed, and the dimensional accuracy of the processed workpiece cannot be guaranteed. Therefore, it is very necessary to compensate the grinding wheel after dressing.

Since the hardness and wear resistance of diamond grinding wheels are much greater than that of GC cup dressing wheels. Therefore, the abrasive thickness reduced by the diamond grinding wheel in one dressing process is much smaller than the abrasive thickness reduced by the dressing wheel. Fix the position of dressing wheel, when dressing, the grinding wheel advances one dressing amount along the feeding direction, due to the mutual grinding effect, the thickness of the grinding wheel and dressing wheel decreases at the same time. So the size of the amount of dressing should be equal to the amount of reduction of the grinding wheel and the reduction of the dressing wheel and the amount.

In actual processing, only one grinding wheel thickness reduction needs to be compensated. After testing, usually, the grinding wheel thickness reduction is about one twentieth of the total amount of correction. For example, when the total correction amount is 0.03 mm, the processing compensation of the grinding wheel thickness is 0.0015 mm.

This control and compensation method for automatic dressing of grinding wheels has been used in a large number of applications in grinding processing. Through a long period of uninterrupted continuous trial grinding, machine tools processed workpiece size consistency has been well controlled, the size error does not exceed 5 microns, proving that the actual effect of this method is very reliable.

Main Features of Moresuperhard Wheel Dresser

.jpg)

- High-speed bus controller, control instruction cycle 1ms, control resolution reaches 0.0001mm.

- Absolute position control of 7 servo axes, no need for origin and limit switches, perfect software limit function, make the equipment run more stable and safe, processing efficiency increased by more than 30%.

- Abundant working modes (single-axis operation, manual mode, automatic mode) and with external handwheel, as well as real-time position feedback display function, so that the equipment debugging is more convenient, and the processing effect is more intuitive.

- The adoption of high-speed response, high-precision servo system and power-down position memory function makes the processing performance better and the use more convenient.

- Real-time position feedback and abnormal alarm on the main interface make the machining process more intuitive, as well as flexible parameter settings, which can be adapted to the processing of more grinding wheel products.

.jpg)

.jpg)

.jpg)