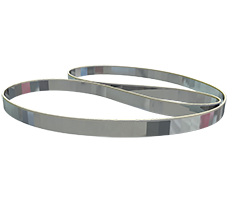

Moresuperhard diamond band saw blade is widely used for cutting semiconductor materials, monocrystalline silicon, polysilicon, silicon ingot, stone, graphite, ceramics, crystal, gem jade, glass, metal and other hard materials.

.jpg)

Feature:

1. Using corrosion and rust resistant high strength stainless steel matrix, the band saw blades has a long working life.

2. Diamond coating is not easy to fall off, and the skew is accurate.

3. Cutting edge is sharp, cutting speed is fast, cutting surface is smooth and flat

.jpg)

Things to pay attention to when using:

1. Adjust the tension of the band saw blade to moderate, too tight easy to break the belt, too loose easy to skew and break the belt.

2. When cutting, be sure to use coolant to remove waste chips in time.

3. The new saw blade must be guaranteed to have the run-in period.

The running time is about 5min with idling and cooling water

The first cut of the saw belt should be fed at half the normal rate, the second cut at 70% of the normal rate, and the third cut back to normal. (The reason is that the tension stress on the surface of the band saw blades is eliminated by running-in. At the same time, after a slower cutting speed, to ensure the full diamond edge. The better the state of the cutting edge, the higher the feed efficiency, the smaller the power consumption, the smaller the relative band saw blades force, so as to improve the service life of the effect)

4. After using the band saw blade for a period of time, it is found that under the same pressure state, when there is deviation or the forward speed is significantly slowed down, it is necessary to reduce the feed pressure and reduce the feed speed to improve the service life of the saw blade.

.jpg)

.jpg)