In the realm of high-precision manufacturing, achieving micron-level accuracy is no longer a goal but a necessity. Today, we are thrilled to highlight how the Stähli DLM 705 double face grinding machine, paired with our advanced double-end vitrified CBN grinding wheels, is redefining precision standards across industries.

Unmatched Grinding Performance

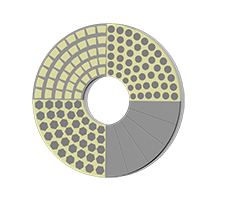

At the core of this cutting-edge solution lies our high-quality

double-end vitrified CBN grinding wheels, engineered to deliver exceptional results. With a diameter of 720 mm and a grit size of 200/230#, these wheels are designed to handle the most demanding grinding tasks with unparalleled efficiency.

Whether processing hydraulic valve plates, silicon carbide seal rings, or other precision components, the combination of Stähli DLM 705 and our vitrified CBN wheels ensures:

- Hydraulic valve plates: Achieving a thickness tolerance of 20±0.002mm and a flatness of 0.001mm, meeting the strictest requirements of hydraulic systems.

- Silicon carbide seal rings: Double-sided parallel grinding with a parallelism of ≤1μm, guaranteeing leak-proof performance in critical applications.

- Dual-plate lapping: Unprecedented precision of ±0.0005mm, setting a new benchmark for ultra-fine grinding.

Engineered for Versatility

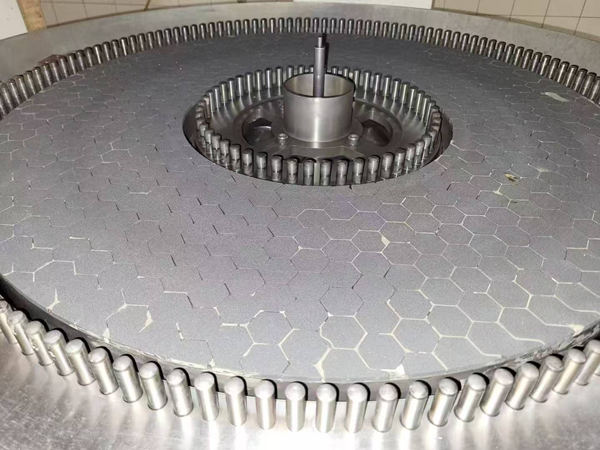

Our vitrified CBN grinding wheels are not only about precision—they’re also built for versatility. The Stähli DLM 705, when equipped with our wheels, can be seamlessly integrated with

planetary gears, enabling efficient processing of complex workpieces in batch production. This flexibility makes it an ideal solution for industries ranging from hydraulics and aerospace to automotive and precision engineering.

.jpg)

Why Choose Our Double-end Vitrified CBN Grinding Wheels?

- Superior Material: Vitrified CBN (Cubic Boron Nitride) offers exceptional hardness and heat resistance, ensuring longer wheel life and consistent performance even under heavy loads.

- Precision Engineering: Each wheel is crafted to exact specifications, with a 720mm diameter and 200/230# grit size optimized for fine finishing and tight tolerances.

- Proven Results: From hydraulic valve plates to carbide seal rings, our wheels deliver repeatable accuracy, reducing scrap rates and boosting production efficiency.

Elevate Your Manufacturing Standards

In a market where precision defines success, the Stähli DLM 705 paired with our vitrified CBN grinding wheels is your key to staying ahead. Whether you’re producing critical components for hydraulic systems or high-performance seal rings, our solutions ensure that every workpiece meets the most stringent quality standards.

Ready to transform your grinding processes? Contact us today to learn how our double-end vitrified CBN grinding wheels can enhance the performance of your Stähli DLM 705 machine and elevate your manufacturing capabilities.

.jpg)

.jpg)