Main Specification and Parameter:

l Max. Diameter of processed work piece (mm) 280

l Max .Height of processed work piece (mm) 100

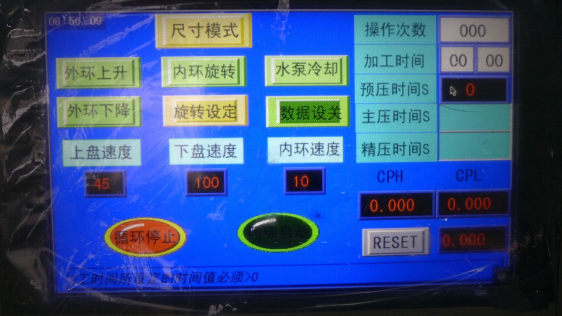

l Upper plate power/speed (kw/rpm) 11/5~80

l Lower plate power/speed (kw/rpm) 11/5~80

l Internal ring power/speed(kw/rpm) 3 /5~65

l Machine Min. inlet pressure(Mpa) 0.8

l Machine outer dimension L*B*H(mm) 2100x2300x2700

l Machine weight (kg) 6000

Scope of supply:

| Item |

Quantity |

Note |

| High precision Grinding machine |

1 set |

SKF-GMM1000 |

| Dressing Grinding wheel |

1 set |

|

| Dressing Wheel Carrier |

1 set |

|

Work piece Carrier |

1 set |

Cooling tank (300L) Filter paper1 roll |

| Coolant System |

1 set |

|

Filter Paper+ Magnetic Separator

system |

1 set |

|

| Semi-auto loading/unloading table |

1 set |

|

| Toolbox |

1 set |

|

| Operating Manual |

1 set |

Packing list and certificate |

| Diamond/CBN Grinding wheel |

1 set |

|

Installation and debugging of High Precision Double Side Grinding and Lapping Machine

Pre-acceptance document is provided by Buyer,the workpiece of pre-acceptance and final acceptance should reach to the drawing requirement when finish fine grinding.

On-site debugging in Buyer’s plant.:

Responsibility

a. Supplier is responsible for on-site installation, debugging and machine technical performance requirement in Buyer's plant

b. Supplier is responsible for the professional tooling for installation and debugging.

c. Supplier is responsible to offer configured public facility and operator requirement for installation and debugging.

d. Buyer is responsible to offer configured public facility and arrange operator to assist supplier to finish on-site installation and debugging in Buyer's plant.

e. Buyer is responsible to provide work piece to be tested and cooling oil for debugging(self-configured slurry is acceptable)

l Installation and debugging period: 2-7 working days. If any defect running while debugging to postpone working period, Supplier shall be responsible for the related expense.

l Installation inform: Buyer should inform Supplier by written for machine debugging when finishes configured public facility and machine arrival.

l Supplier should arrive in Buyer's plant in 3 days for installation and debugging when received Buyer's inform

l During installation and debugging, Supplier is responsible for food and

Accommodation.

During installation and debugging, Supplier people must follow the management rule of Buyer's plant

During installation and debugging, if any special case to happen long term installation and debugging without finishing, both parties solve with negotiation.