Centerless Grinding: A Comprehensive Guide

Grinding is a machining process that removes material from a workpiece using abrasive cutting tools. Centerless grinding is a particular type of grinding in which cylindrical objects are ground without the use of a center or a spindle. This article will provide a comprehensive guide on centerless grinding and its applications, advantages, and types of machines.

What is centerless grinding process?

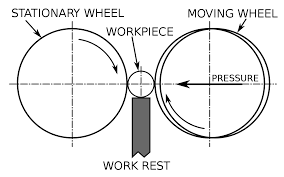

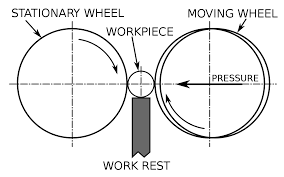

Centerless grinding is a machining process that involves removing material from a cylindrical object by using abrasive cutting tools. In this process, the object being ground is supported by a work rest blade and a regulating wheel that is positioned opposite to the grinding wheel. The grinding wheel rotates at high speeds and removes material from the object, while the regulating wheel controls the rotation speed and feed rate of the workpiece. The workpiece is fed through the grinding zone between the two wheels, and the grinding action takes place between the grinding wheel and the workpiece.

Why use centerless grinding?

Centerless grinding is used for a variety of reasons, including:

High precision: Centerless grinding is capable of achieving high levels of precision and accuracy due to its unique design. The absence of a center or spindle allows for more precise grinding of cylindrical objects.

Cost-effective: Centerless grinding is a cost-effective method for machining cylindrical objects, as it requires less setup time and fewer tools than other grinding methods.

High production rates: Centerless grinding is a quick and efficient method for grinding large volumes of cylindrical objects.

Types of centerless grinding machines:

There are several types of centerless grinding machines, including:

In-feed machines: In-feed centerless grinding machines are used to grind workpieces with relatively complex shapes, such as hourglasses, camshafts, and valves. The grinding wheel is fed into the workpiece until the desired shape and size are achieved.

Through-feed machines: Through-feed centerless grinding machines are used to grind cylindrical objects with a consistent diameter along the entire length of the workpiece. The workpiece is fed through the grinding wheels and exits on the opposite side.

End-feed machines: End-feed centerless grinding machines are used to grind objects with a reduced diameter as they exit the grinding wheel. The workpiece is fed into the grinding wheel until it reaches the desired size, and then it is removed.

In conclusion, centerless grinding is a unique machining process that offers many advantages, including high precision, cost-effectiveness, and high production rates. There are several types of centerless grinding machines, each with its own specific applications and advantages. If you are in need of precision grinding services for your cylindrical objects, centerless grinding may be the ideal solution for you.

Moresuperhard's Centerless Grinding Machines With Hign Precision:

High Precision CNC Centerless Grinder:

►High Precision Centerless Grinding Machines Models:

-FX12CNC

-FX18CNC-4

►Conventional High Precision Centerless Grinding Machines Models:

-FX12S

-FX18S/AS/BS

-FX18HS(Static Pressure Spindle)

-FX20S

►Broad Applications:

-Automotive Industry: shafts, pins, valves, and bearings

-Aerospace Industry: turbine shafts, landing gear components, and fuel system parts

-Medical Industry

-Tool and Die Industry

-Bearings industry

-Tool and Die Industry: cutting tools, punches, and dies with high accuracy and surface quality