We recently received feedback from an Iranian customer who encountered an issue with the plated CBN grinding wheels they purchased from us. The customer reported that the wheels were causing burns on the workpiece during grinding.

Our service team immediately engaged with the customer to understand their specific application and the type of grinding method used, dry or wet. We reviewed a machining video provided by the customer and determined that the workpiece material was likely steel.

We explained to the customer the possible causes of burns during the grinding process:

1. Large grinding volume, when the grinding volume will make the surface temperature of the workpiece rise, which may produce burns.

2. The grinding wheel is not timely dressing, when grinding a certain amount of workpiece, the grinding wheel surface will have residual workpiece material blocking the grinding wheel, if not timely dressing off, it will produce burns. But this customer is using electroplated CBN grinding wheel, there is no dressing problem.

3. Cooling method, the effective addition of chip liquid during grinding can take away the heat generated during the price processing, thus avoiding burns. The customer processing mode is dry grinding, but the site conditions can join the cutting fluid is not sure.

4. Workpiece material, the higher the hardness of the workpiece material, the more heat generated by grinding, but the material is too soft, it is easy to block the grinding wheel, but the processing surface temperature rises sharply. At this time, we have not got the customer processing material specific information, to be further confirmed.

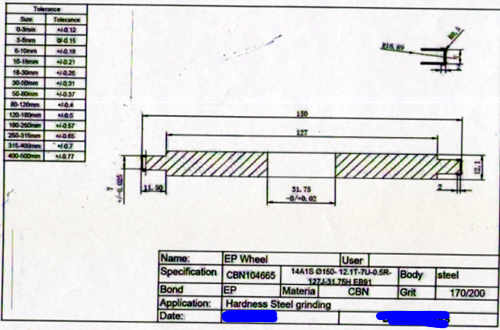

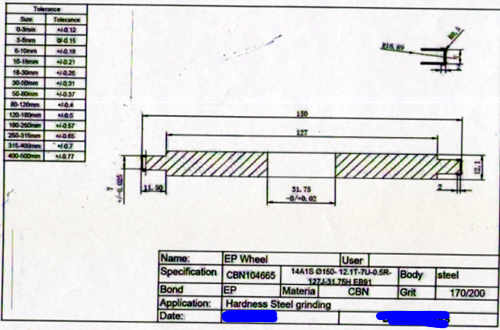

To resolve the issue, we recommended that the customer consider using coarser grit size wheels, such as 120# or even 80/100#, as well as using resin bond wheels instead of electroplated bond. Resin bond offers a degree of elasticity during large grinding volume processing, which can reduce grinding depth and the risk of burning.

---EDITOR: Miya Ma,Jackie Wang

---POST: Jackie Wang