The customer service department of Moresuperhard recently received continuous feedback from customers about

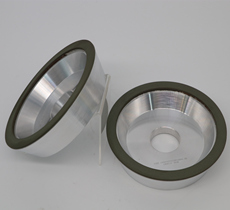

diamond grinding wheels used to grind glass stoppers of whisky crystal bottles.

At the beginning, the customer encountered the problem of grinding wheel burn in the process of using. Our production and engineering department received feedback and suggested that the diamond particles may have lost their sharp corners in grinding and could not fall off in time, thus blocking the pores and causing burns. Therefore, our engineers recommend that customers use higher-grade diamonds to improve the sharpness and grinding time of grinding.

What's more, engineers also adjusted the structure of the bonding so that the diamond abrasive particles can fall off more easily.

Final feedback:

the adjusted resin diamond grinding wheels did not have any problems during use, and fully met the customer's requirements.

Please get detailed communication contents as follows:

The first feedback of diamond grinding wheels for glass stoppers of whisky crystal bottles:

Hi Alan,

Now they were grinding glass stoppers for crystal whiskey bottles. The contact surface was solid with a diameter of 50 mm. With a larger contact surface, sparks occurred in the contact surface of the grinding wheel and the workpiece. This occurred with both the D25 and D39 wheel grit sizes when they were about half used up. The plates were sharpened with BORID SiC sharpening stone grit size 200 and 320, but there was no significant change. They replaced the plates with new ones and the spark treatment was the same.

What do you think could be improved? I thing that we might now have hardness at the limit point and we could go back a bit to a softer feature of the sanding plate, so that we will have a good grip even on a larger contact surface, but I don't think we need much softer..

The second feedback of diamond grinding wheels for glass stoppers of whisky crystal bottles:

The second feedback of diamond grinding wheels for glass stoppers of whisky crystal bottles:

I visited customer for who we did update wheel in grit size D25 and new position D39.

First about wheels D25.

11A2-D:150-W:10-X:10-E:7-T:20 D25 C100S Vmax.63m/s Wet

We got target what customer wish. We increased wheel life ~40-50hours depend workpieces and still keep good grinding grip on the glass.

Wheel D39

11A2-D:150-W:10-X:10-E:7-T:20 D39

also work good . Customer saw one difference between this two wheels and our D46.

The wheel D46 after sharpening with stone wish a short time a little burning. Generally work good but after sharpening is new bond on D25 and D39 better.. The wheel with bond RB-GW work after

sharpening good without any problem.

11A2-D:150-W:10-X:10-E:7-T:20 D46 RB Vmax.63m/s Wet

11A2-D:150-W:10-X:10-E:7-T:20 RB Vmax.63m/s Wet

11A2-D:150-W:10-X:10-E:7-T:20 RB Vmax.63m/s Wet

11A2-D:150-W:10-X:10-E:7-T:20 RB Vmax.63m/s Wet

11A2-D:150-W:10-X:10-E:7-T:20 RB Vmax.63m/s Wet

11A2-D:150-W:10-X:10-E:7-T:20 D126 RB Vmax.63m/s Wet

11A2-D:150-W:10-X:10-E:7-T:20 RB Vmax.63m/s Wet

11A2-D:150-W:10-X:10-E:7-T:20 RB Vmax.63m/s Wet

With a global development strategy and comprehensive multilingual business departments, Moresuperhard keeps an eye on the latest developments in the global grinding industry and is committed to providing high-quality and efficient grinding products and services to our customers worldwide! We also accept customized orders to suit your needs.

If you have any questions about

resin diamond grinding Wheels

, please feel free to contact us! You can leave us your questions below, and we will contact you as soon as possible!