Vertical Grinding Machine

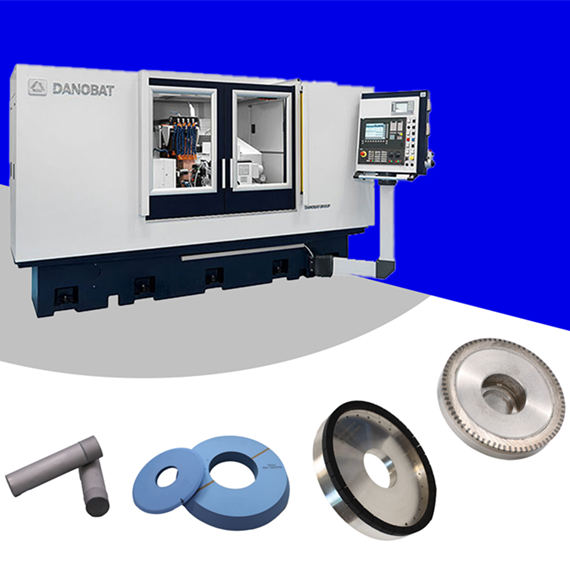

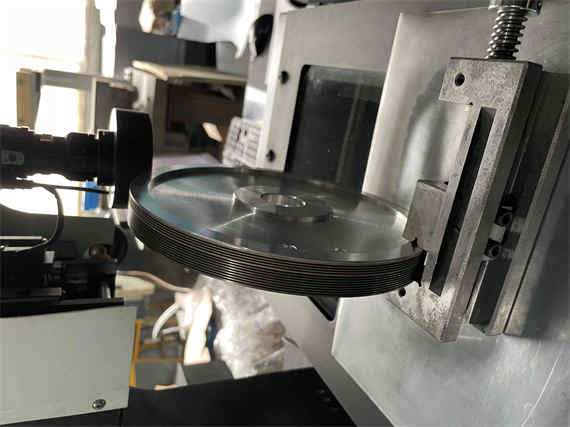

1. The machine is a gantry structure, composed of double columns, beams, and beds to form a closed rigid frame structure. A transverse drag plate is arranged on the beam, and a vertical grinding head is respectively installed on the transverse drag plate.

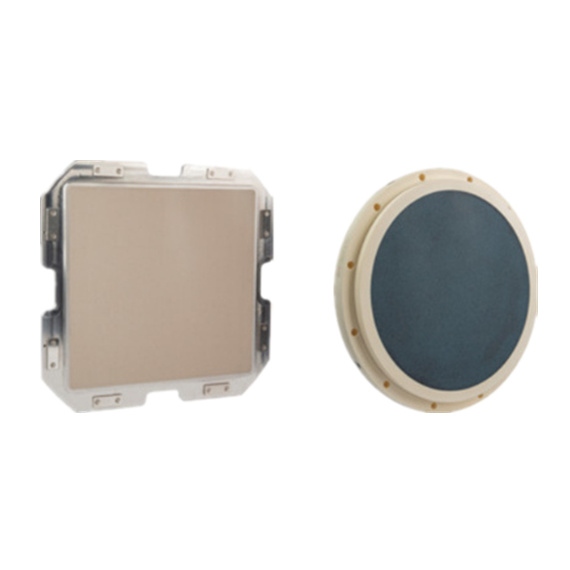

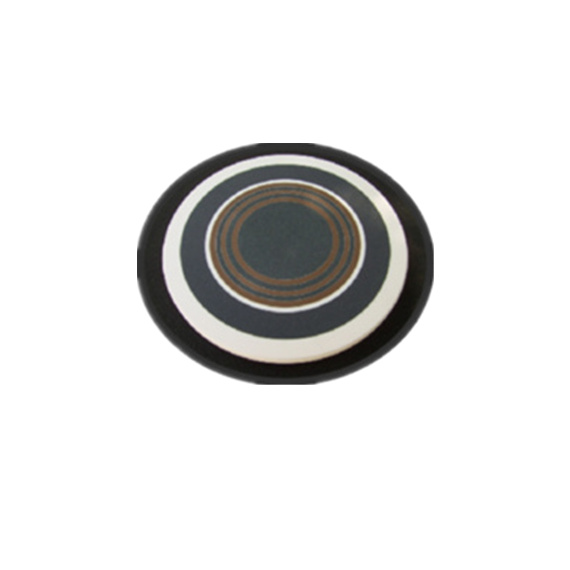

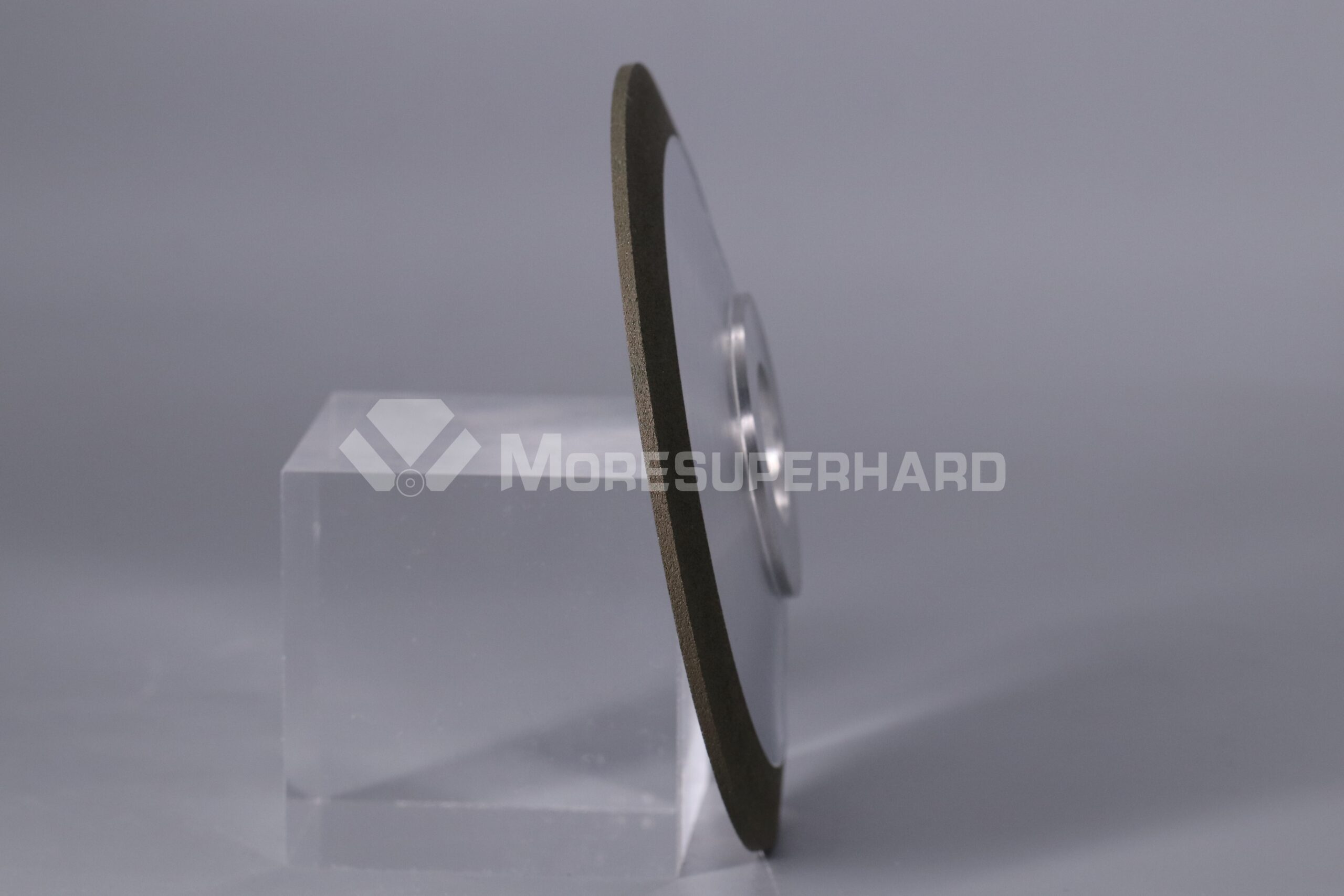

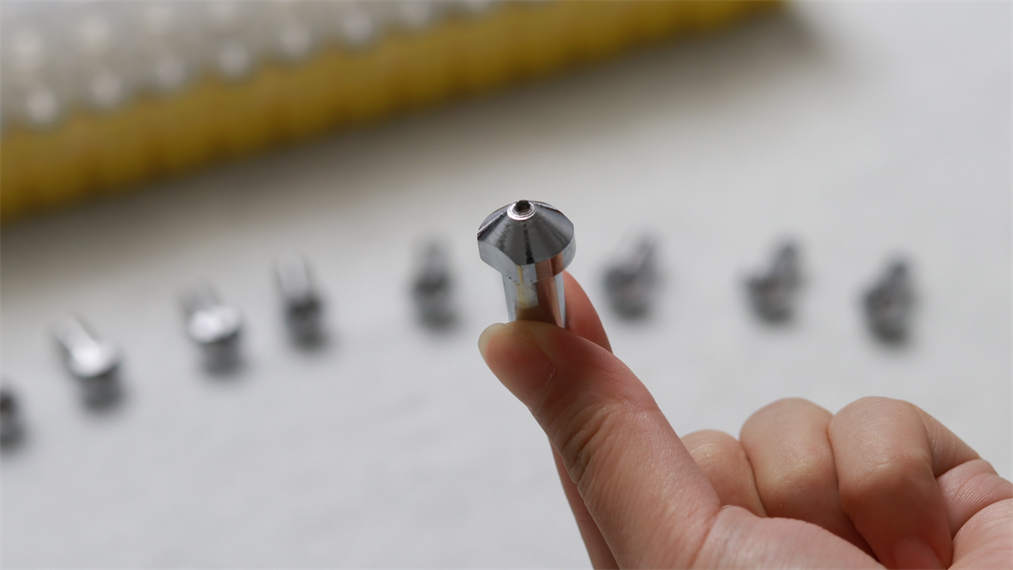

2. The diamond roller dresser is installed at one end of the table, which is used to trim the side and the bottom surface respectively.

3. The machine tool control adopts the German Siemens or Japan FANUC system, which automatically controls the vertical and transverse feed of the grinding head, hydraulic drive of the workbench, and is equipped with the hand-held electric handwheel.

4. Cooling filter system: When grinding and grinding wheel dressing, the workpiece is cooled and the grinding wheel is washed. Filter using magnetic separator, paper filter and natural settlement three filtration. The coolant flow rate is 600L.