Motorized Spindle Chiese Manufactuor for Tool Grinding Machines

1.Constant power section design reduces the cost of the inverter.

2.Reliable life with the application of P4 precision ceramic ball bearings.

3. Low heat loss with use of Copper rotor motor or imported motor.

Based on the above features, our high frequency and high speed spindles play the important role in improving the production efficiency and machining quality.

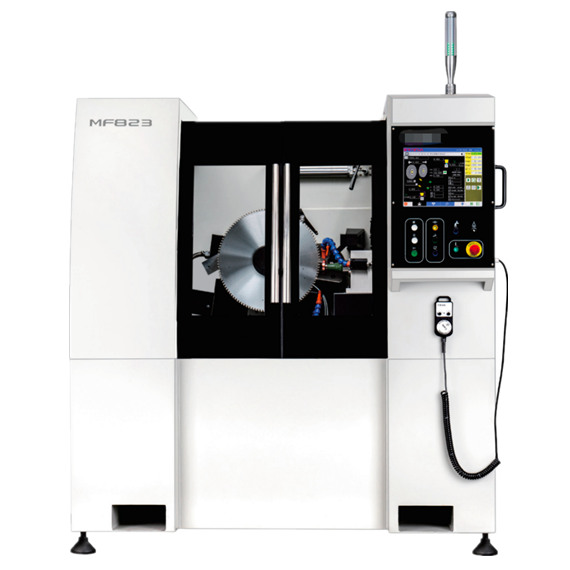

Double Head Grinding Spindle Product performance indicators

Installation size: φ150×290, φ180×293, φ150×322, etc.

Toolholder interface: HSK-F50 standard taper hole

Accuracy: Internal hole and end runout ≯ 0.002mm at both ends; runout ≯ 0.005mm after installation

Runout after shank installation ≯ 0.005mm

Vibration: ≯ 0.4mm/s (RMS) in the full speed range

Rated power: *7.5kW (S1)

Rated speed: 6000r/min

Rated torque: 12Nm

Rated voltage: 380V

Motor type: Permanent magnet synchronous motor

Lubrication method: grease lubrication

Sealing method: gas seal + mechanical seal

Bearing brand: NSK